Ionic curing agent and red mud fly ash gel material

A technology of cementitious materials and curing agents, applied in cement production, etc., can solve the problem of large amount of curing agents, and achieve the effects of easy operation, low price and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

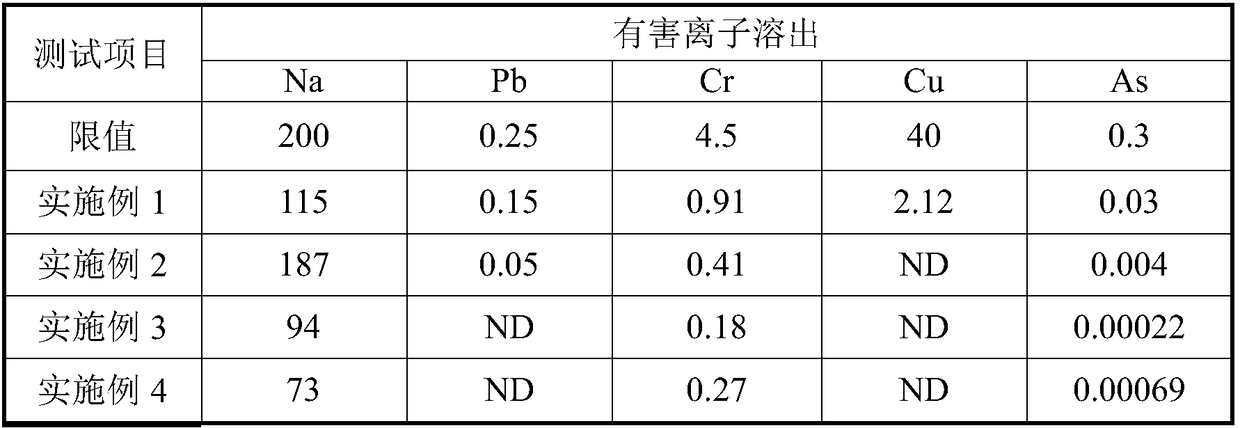

Examples

Embodiment 1

[0022] The present embodiment provides a kind of ion curing agent, and described ion curing agent comprises layered double metal hydroxide: 25g, ammonium chloride 25g.

[0023] This embodiment also provides a red mud fly ash cementitious material, the raw material is 12kg of red mud, 6kg of fly ash, 1kg of desulfurized gypsum, 1kg of lime, 50g of ion curing agent (25g of layered double metal hydroxide, chlorinated Ammonium 25g), the required amount of water is 4.53kg.

[0024] The preparation steps of the red mud fly ash cementitious material are as follows:

[0025] a. All solid raw materials are added to the mixer according to the proportion and mixed evenly.

[0026] b. Weigh 0.25% ionic curing agent with the total content of solid raw materials and add it in the form of external mixing and mix evenly.

[0027] c. Add water in proportion to the evenly mixed dry ingredients, and then fully stir evenly.

Embodiment 2

[0029] The present embodiment provides a kind of ion curing agent, and described ion curing agent comprises layered double metal hydroxide: 30g, ammonium chloride 20g.

[0030] This embodiment also provides a red mud fly ash cementitious material, the raw material is red mud 12kg, fly ash 6kg, desulfurization gypsum 1kg, lime 1kg, ion curing agent 50g (layered double metal hydroxide 30g, chlorinated ammonium 20g), the required amount of water is 4.57kg.

[0031] The preparation steps of the red mud fly ash cementitious material are as follows:

[0032] a. All solid raw materials are added to the mixer according to the proportion and mixed evenly.

[0033] b. Weigh 0.25% ionic curing agent with the total content of solid raw materials and add it in the form of external mixing and mix evenly.

[0034] c. Add water in proportion to the evenly mixed dry ingredients, and then fully stir evenly.

Embodiment 3

[0036] The present embodiment provides a kind of ion curing agent, and described ion curing agent comprises layered double metal hydroxide: 60g, ammonium chloride 40g.

[0037] This embodiment also provides a red mud fly ash cementitious material. The raw materials are 12kg red mud, 6kg fly ash, 1kg desulfurized gypsum, 1kg lime, 100g ion curing agent (60g layered double metal hydroxide, chlorinated ammonium 40g), the required amount of water is 4.57kg.

[0038] The preparation steps of the red mud fly ash cementitious material are as follows:

[0039] a. All solid raw materials are added to the mixer according to the proportion and mixed evenly.

[0040] b. Weigh 0.5% ion curing agent with the total content of solid raw materials and add it in the form of external mixing and mix evenly.

[0041] c. Add water in proportion to the evenly mixed dry ingredients, and then fully stir evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com