Microwave refrigerated sponge cake dough, and its making method

A technology of sponge cake and microwave freezing, applied in the field of food processing, can solve the problems of lack of flavor, short shelf life, sudden decrease in flavor, etc., and achieve the effects of improving taste and flavor, convenient transportation and uniform organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

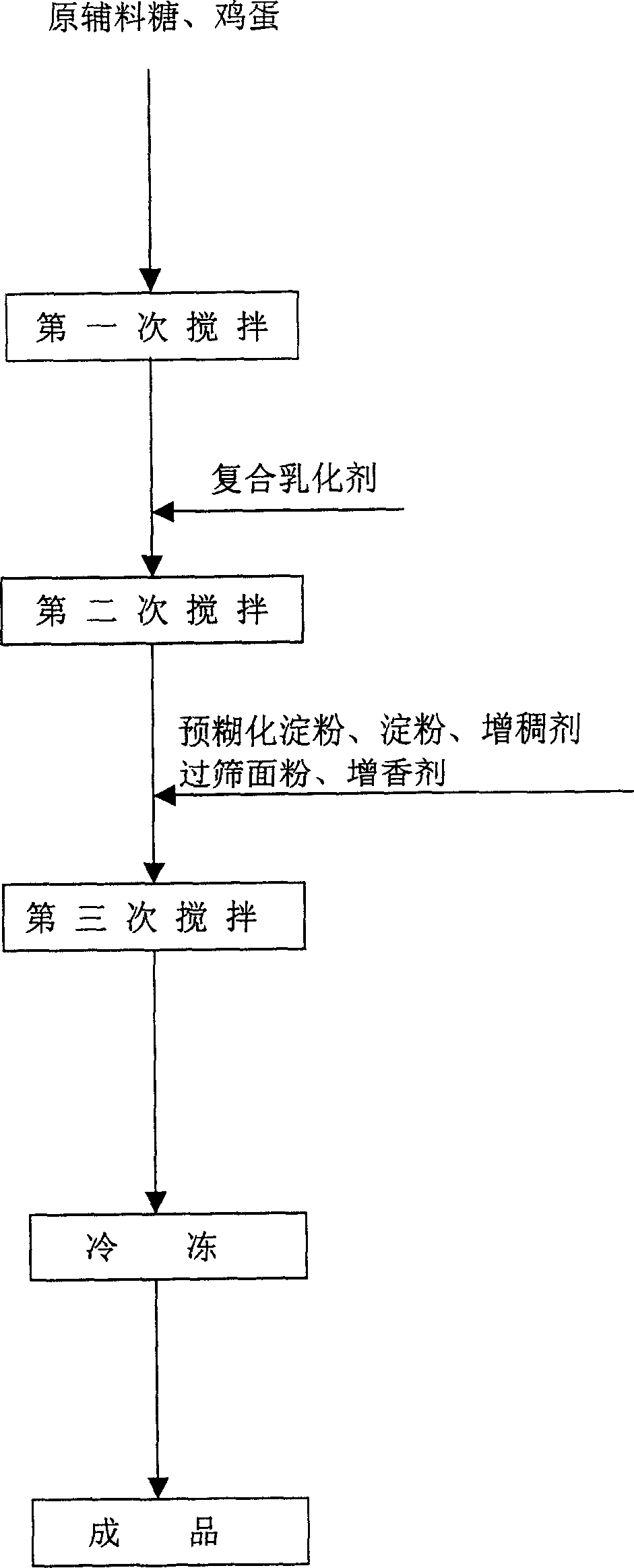

Method used

Image

Examples

Embodiment 1

[0022] Embodiment one: its composition and proportioning are by (weight percentage) in the embodiment of the present invention:

[0023] In the embodiment of the present invention, the compound emulsifier configuration is first carried out: take sodium stearoyl lactylate (SSL) and diacetyl tartaric acid mono(di) fatty acid glyceride (DATEM) and monoglyceride: 0.2, mix uniformly by 2:1:2 , then add water: 15, heat slowly, the heating temperature is: 85°C, and stir continuously to dissolve the emulsifier, and finally stir to lower the temperature to 55°C, stop stirring and cool the temperature to ambient temperature, ready for use;

[0024] Take sugar: 24 and eggs: 26 and whip for 2 minutes. After the sugar dissolves, add the compound emulsifier prepared first, and beat at high speed until milky white or 2.5 times the total amount before whipping;

[0025] The pre-gelatinized starch is pre-gelatinized wheat starch: 3, the starch is corn starch: 2, the thickener is xanthan gum: 0...

Embodiment 2

[0028] Embodiment two: its composition and proportioning are by (weight percentage) in the embodiment of the present invention:)

[0029] In the embodiment of the present invention, the compound emulsifier configuration is first carried out: take sodium stearoyl lactylate (SSL) and diacetyl tartaric acid mono(di) fatty acid glyceride (DATEM) and monoglyceride as: 1, mix uniformly by 2:1:2 , then add water: 17, heat slowly, the heating temperature is: 95 ° C, and continue to stir to dissolve the emulsifier, and finally stir to reduce the temperature to 60 ° C, stop stirring and cool the temperature to ambient temperature, ready to use;

[0030] Take sugar: 26 and eggs: 28 and beat for 1 minute. After the sugar dissolves, add the compound emulsifier prepared first, and beat at high speed until milky white or 3 times the total amount before whipping;

[0031] Pre-gelatinized starch is pre-gelatinized corn starch: 5, starch is wheat starch: 4, thickener is

[0032] Guar gum: 0.3,...

Embodiment 3

[0034] Embodiment three: its composition and proportioning are by (weight percentage) in the embodiment of the present invention:

[0035] In the embodiment of the present invention, the complex emulsifier configuration is first carried out: take sodium stearoyl lactylate (SSL) and diacetyl tartaric acid mono(di) fatty acid glyceride (DATEM) and monoglyceride: 0.6, mix uniformly by 2:1:2 , then add water: 16, heat slowly, the heating temperature is: 90 ° C, and continue to stir to dissolve the emulsifier, and finally stir to reduce the temperature to 57 ° C, stop stirring and cool the temperature to ambient temperature, ready to use;

[0036] Take sugar: 25 and eggs: 27 and beat for 1.5 minutes. After the sugar dissolves, add the compound emulsifier prepared first, and beat at high speed until milky white or 3.5 times the total amount before whipping;

[0037] Pre-gelatinized starch is pre-gelatinized tapioca starch: 4, starch is potato starch: 3, thickener pectin: 0.2, sieved...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com