Thermoplastic starch plastic

A thermoplastic starch and plastic technology, applied in the field of plastics, can solve the problems of poor heat resistance and water resistance, rising product cost, and reduced mechanical properties, and achieves the improvement of heat resistance and water resistance, simple production process, and improved physical properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

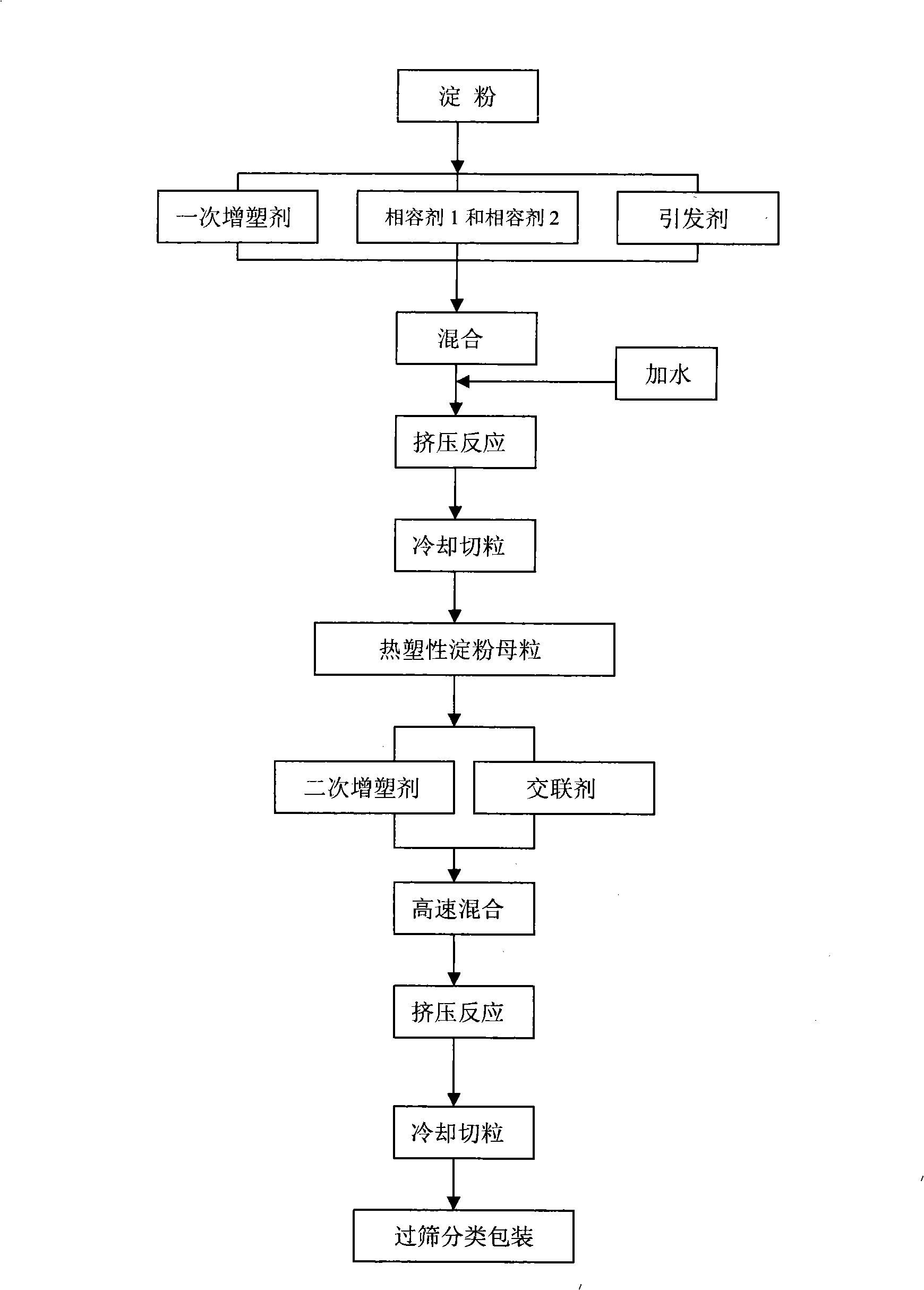

[0043] Preparation method and production process of the present invention, such as figure 1 Shown:

[0044] First, measure starch 110Kg, glycerin (primary plasticizer) 17.5Kg, maleic anhydride (compatibilizer 1) 20Kg, tert-butyl peroxide (initiator) 0.035Kg and maleic acid di The weight of octyl ester (compatibilizer 2) 3Kg, and carry out mixing and stirring by high-speed kneader, obtain mixed material;

[0045] Then measure the weight of water according to the number of parts by weight, and add 17.5Kg of water and the mixed material into the extruder, and carry out extrusion reaction through the extruder, during which the temperature control range of each interval is between 140 ° C and 160 ° C, Then, after the extrusion reaction, a good grafting effect can be obtained, the material after the extrusion reaction is extruded, cooled and pelletized, and thermoplastic starch masterbatch is obtained;

[0046] Then all the thermoplastic starch masterbatches are stirred with glyce...

Embodiment 2

[0050] Its preparation method and production process, such as figure 1 Shown:

[0051] First, measure starch 120Kg, ethylene glycol (primary plasticizer) 20Kg, maleic anhydride (compatibilizer 1) 10Kg, tert-butyl peroxide (initiator) 0.02Kg and maleic acid according to components and parts by weight The weight of dioctyl ester (compatibilizer 2) 1Kg, and carry out mixing and stirring by high-speed kneader, obtain mixed material;

[0052] Then measure the weight of water according to the number of parts by weight, and add 17.5Kg of water and the mixed material into the extruder, and carry out extrusion reaction through the extruder, during which the temperature control range of each interval is between 140 ° C and 160 ° C, Then, after the extrusion reaction, a good grafting effect can be obtained, the material after the extrusion reaction is extruded, cooled and pelletized, and thermoplastic starch masterbatch is obtained;

[0053] Then all the thermoplastic starch masterbatc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Membrane thickness | aaaaa | aaaaa |

| Tear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com