Preparation method of Pickering emulsion with stable starch nanoparticles

A technology of starch nanometer and granular emulsifier, applied in the field of Pickering emulsion preparation, can solve the problems of time-consuming, low yield, poor emulsion stability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

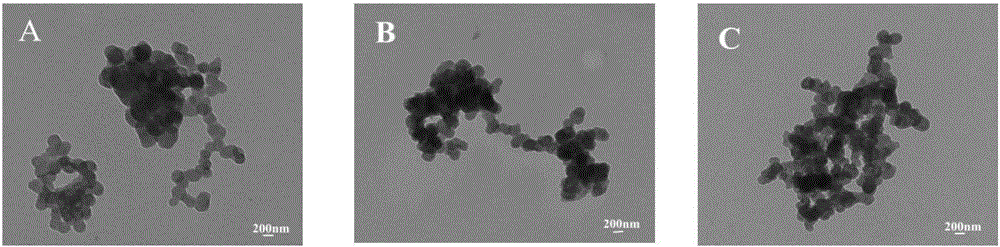

[0043] Preparation of starch nanoparticle emulsifier by alcohol method: choose cassava, sweet potato, and cornstarch, take 5g each, disperse into 100ml water respectively (starch concentration is 5%), then gelatinize in boiling water bath for 30min, make cornstarch paste liquid, sweet potato starch gelatinization liquid and tapioca starch gelatinization liquid. Get 100ml of dehydrated ethanol respectively, add dropwise in above-mentioned three kinds of gelatinized liquid (the volume ratio of every kind of gelatinized liquid and dehydrated ethanol is 1:1), stir while adding, control the magnetic stirrer The rotational speed was 1500 rpm, and the stirring was continued for 2 hours after the titration, and then the suspension was centrifuged, and the precipitate was freeze-dried to obtain starch nanoparticle powder. Figure 1a It is the transmission electron microscope image of different starch nanoparticles, corresponding to tapioca starch nanoparticles, sweet potato starch nanop...

Embodiment 2

[0046] Mix soybean oil and water at a volume ratio of 1:1 to prepare an oil-water mixture, and take three oil-water mixtures, each of which is 100 mL. Take 1 g each of the corn nanoparticles, sweet potato nanoparticles and tapioca starch nanoparticles prepared in Example 1, and add them to the oil-water mixture prepared above, control the temperature of the mixture to 25°C, and use a high-speed homogenizer at a temperature of 10000rmp Homogenize at a speed of 2 minutes to obtain a Pickering emulsion. Figure 2a Stability observation diagrams of Pickering emulsions prepared for different types of starch nanoparticles, from left to right corresponding to the stability observation diagrams of 0h, 1h, 3h, 1day and 7day; Figure 2b Microscopic images of Pickering emulsions prepared for different types of starch nanoparticles, from left to right corresponding to emulsions stabilized by sweet potato starch nanoparticles, tapioca starch nanoparticles and corn starch nanoparticles; F...

Embodiment 3

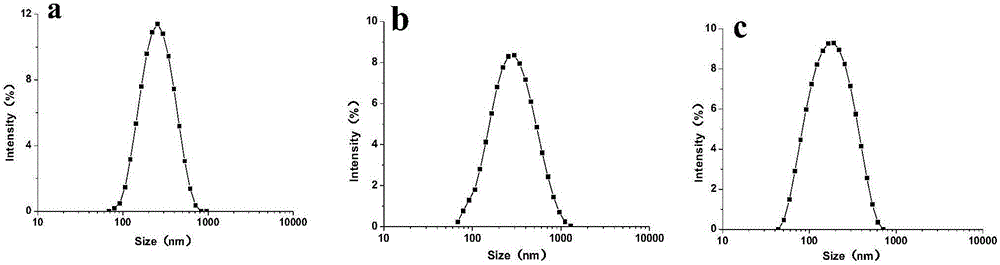

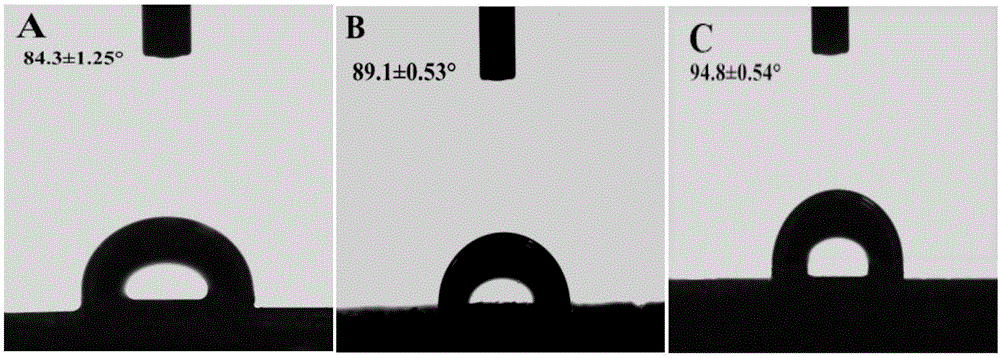

[0049] By controlling the speed of the mixer, starch nanoparticles with different particle sizes were prepared. Refer to Example 1 for the specific operation method: select sweet potato starch or corn starch → gelatinize separately → add absolute ethanol dropwise, control the speed of the mixer to 300, 500, 1000, 1500 and 2000 rpm respectively → centrifuge → freeze-dry. Figure 3a The particle size distribution diagram of starch nanoparticles prepared for different stirring speeds, corresponding to sweet potato starch nanoparticles and corn starch nanoparticles from left to right; Figure 3b It is the three-phase contact angle diagram of sweet potato starch nanoparticles, which corresponds to the sweet potato starch nanoparticles prepared under the conditions of 300, 500, 1000, 1500 and 2000 rpm from left to right; Figure 3c It is the three-phase contact angle diagram of corn starch nanoparticles, corresponding to the corn starch nanoparticles prepared under the condition of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com