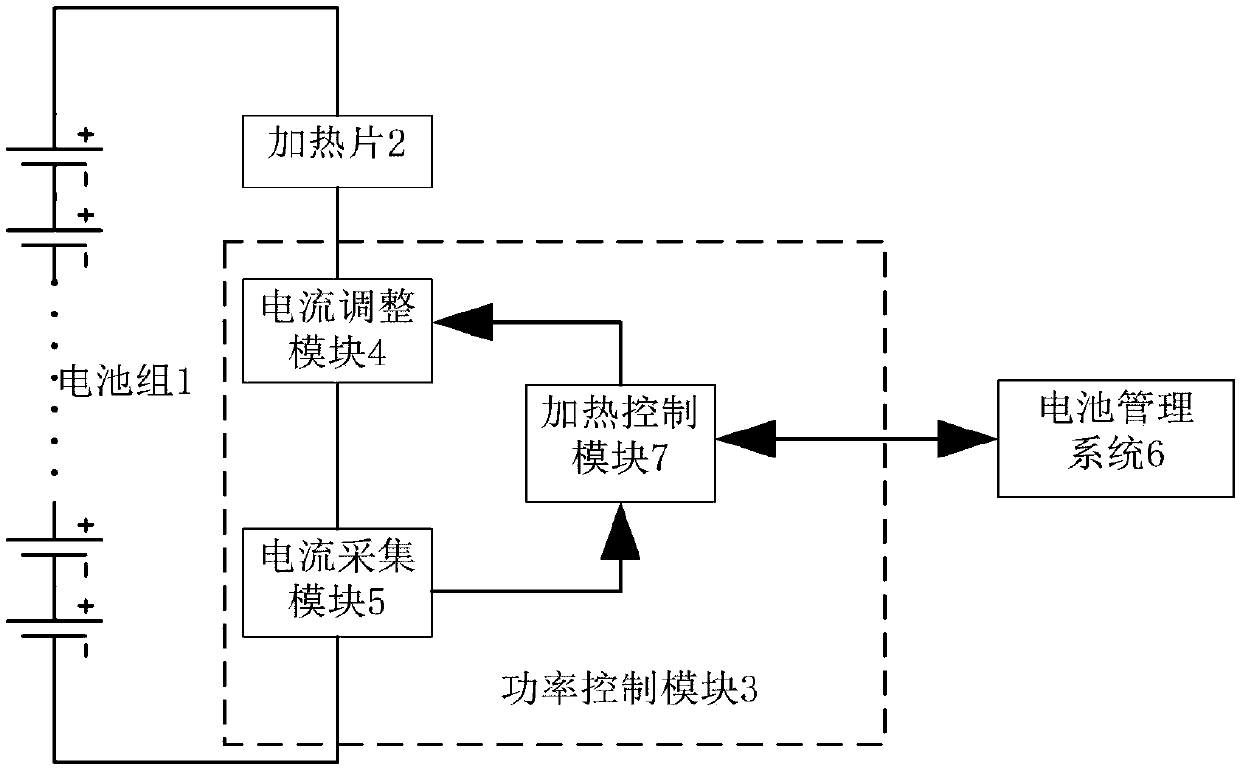

Battery system with adjustable heating speed and control method thereof

A heating speed, battery system technology, applied in the power supply of electric heating circuit, battery/fuel cell control device, battery and other directions, can solve the problems of fast heating rate, low maintenance difficulty, slow heating speed, etc. The effect of long driving range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

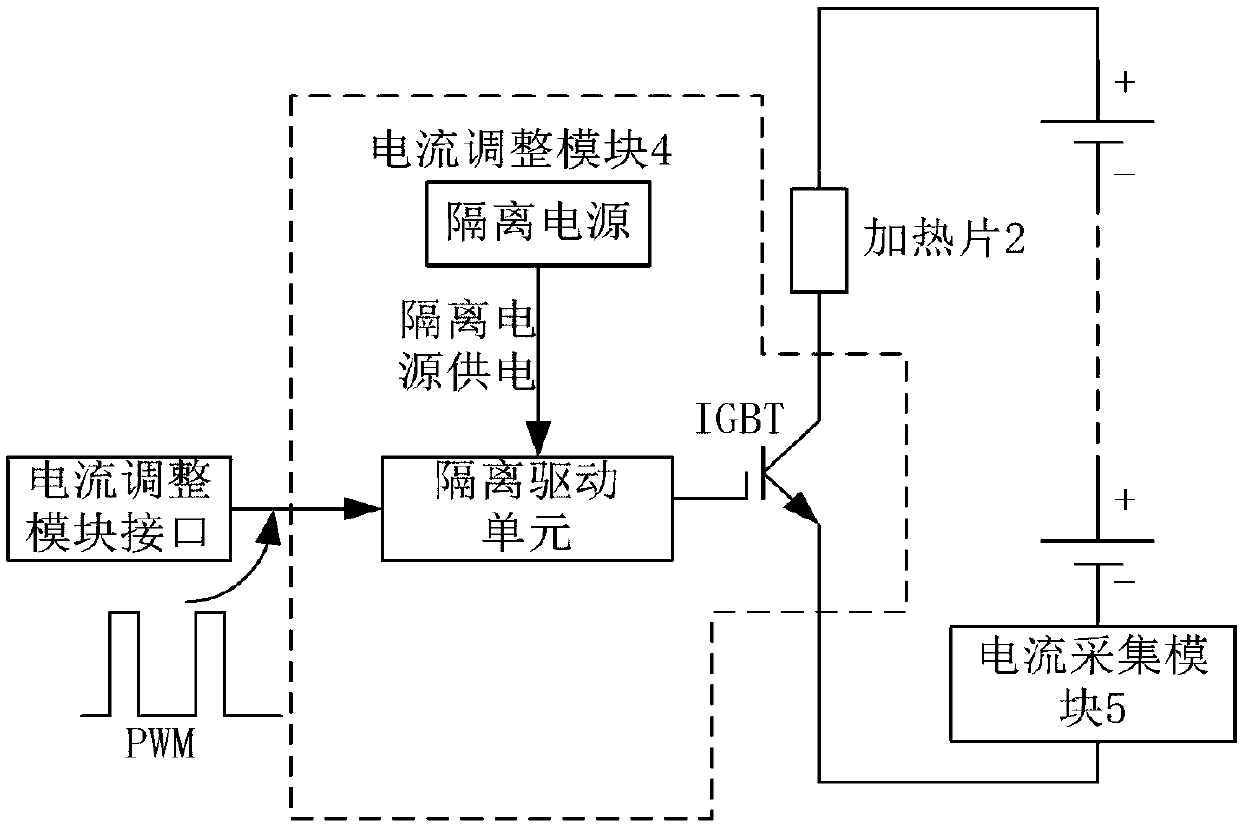

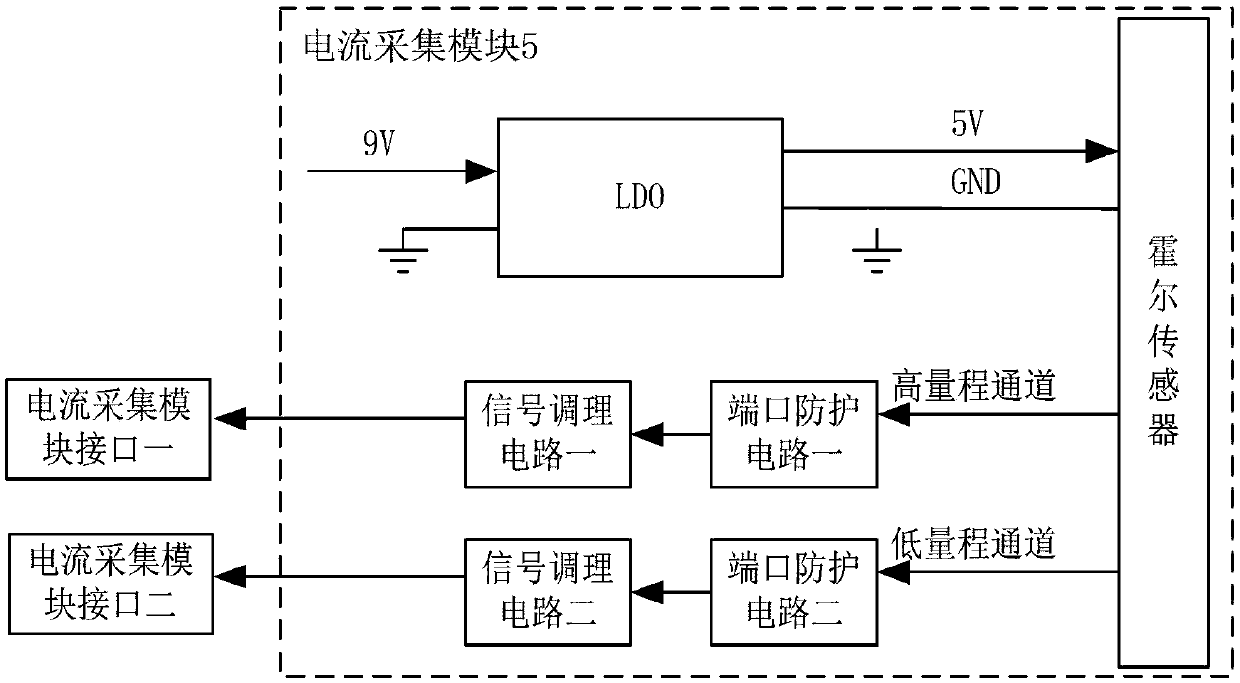

Embodiment 1

[0055] The single battery is a lithium-ion battery with a single capacity of 70Ah and a rated voltage of 3.7V. The battery system is 4 parallel and 36 in series. The battery heater 2 is made of nickel with a resistance of 80mΩ. The heater 2 is built into the battery. The connection mode of 2 is 4 in parallel and 36 in series, the ambient temperature is -20°C, and the battery management system 6 sends the parking heating mode to the heating control module 7 . After the battery management system 6 sends the heating mode to the heating control module 7, the PWM transmission duty cycle is 100%, the heating control module 7 starts quickly, the IGBT is 100% turned on, and heats at the maximum speed, the maximum heating current is 147A, and the temperature of the battery system is The speed rises rapidly every 5°C / min, and when the battery temperature reaches the set stop heating temperature of 10°C, the heating control module 7 stops the heating operation, and the heating stops. At ...

Embodiment 2

[0057] The single battery is a lithium-ion battery with a single capacity of 70Ah and a rated voltage of 3.7V. The battery system is 4 parallel and 36 in series. The battery heater 2 is made of nickel with a resistance of 80mΩ. The heater 2 is built into the battery. The connection mode of 2 is 4 in parallel and 36 in series, the ambient temperature is -20°C, the vehicle is plugged into a DC charger, and the battery management system 6 sends the DC charging heating mode to the heating control module 7 . The heating control module 7 sends a PWM duty cycle of 60%, the heating control module 7 starts, controls the IGBT pulse work, and the heating starts, the heating current is 149A, the output current of the charger is set to 60A, and the temperature of the battery system is set at 5°C / min The speed rises rapidly. When the battery temperature reaches the charging stop heating temperature of 10°C, the heating control module 7 stops the heating action, the heating stops, the charger...

Embodiment 3

[0059] The single battery is a lithium-ion battery with a single capacity of 70Ah and a rated voltage of 3.7V. The battery system is 4 parallel and 36 in series. The battery heater 2 is made of nickel with a resistance of 80mΩ. The heater 2 is built into the battery. The connection mode of 2 is 4 in parallel and 36 in series, the ambient temperature is -20°C, the vehicle is plugged into the AC charging cable, and the battery management system 6 sends the AC charging heating mode to the heating control module 7 . The heating control module 7 sends a PWM duty cycle of 90%, the heating control module 7 starts, controls the IGBT pulse work, and starts heating. The heating current is 139A, the output current of the charger is set to 20A, and the temperature of the battery system is set at 5°C / min. The speed rises rapidly. When the battery temperature reaches the charging stop heating temperature of 10°C, the heating control module 7 stops the heating action, the heating stops, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com