Combustion device of petroleum coke slurry

A combustion device and petroleum coke technology, applied in the direction of burners, combustion methods, combustion types, etc., can solve the problems of low combustion temperature of petroleum coke slurry, increased load of desulfurization equipment, high nitrogen content, etc., to improve flame stability, improve Effect of heating rate and specific surface area increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

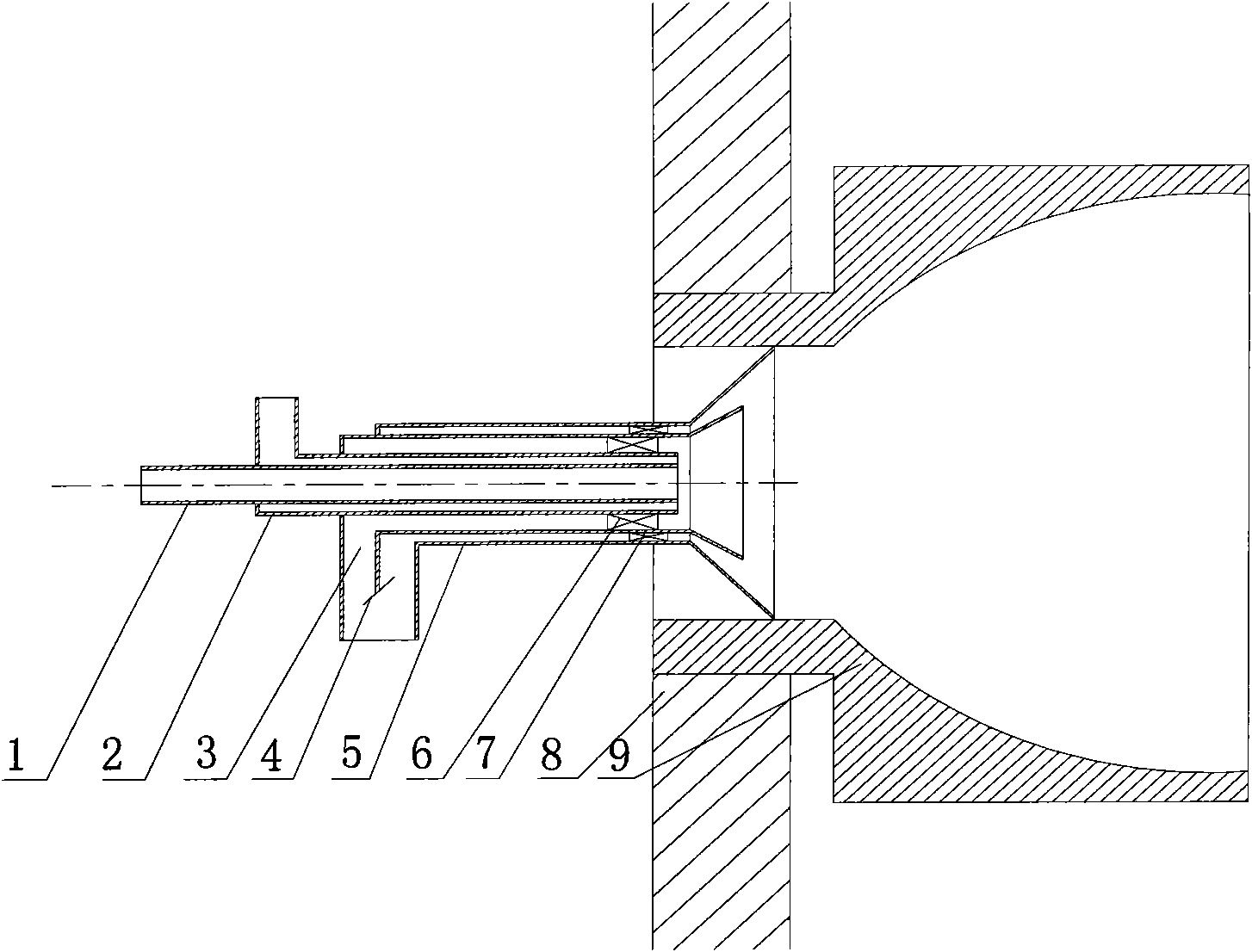

[0014] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0015] see figure 1 , the present invention includes a regenerator cavity 9 with an adjustable insertion depth arranged in the furnace. A fuel / gas on duty nozzle 1 connected to the heat storage chamber 9 is provided, and a petroleum coke slurry atomizing nozzle connected to the heat storage chamber 9 is sequentially set on the outside of the fuel / gas duty nozzle 1 from the inside to the outside. Pipe 2, the inner combustion air nozzle 3 and the outer combustion air nozzle 5, the outlet of the inner combustion air nozzle 3 and the outer combustion air nozzle 5 is a flared structure, the inner combustion air nozzle 3 and the outer The entrance of the combustion-supporting air nozzle 5 is also provided with an air-conditioning baffle 4 for adjusting the air volume, and the inner combustion-supporting air nozzle 3 and the outer combustion-supporting air nozzle 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com