Foamed ceramic material and process for producing foamed ceramic based on layered and sectionalized material preparation and distribution

A technology of layered and partitioned foamed ceramics, which is applied in the field of materials, can solve the problems of long cycle times of foamed ceramics, and achieve the effects of shortening the production cycle, accelerating the heating rate, and reducing the holding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

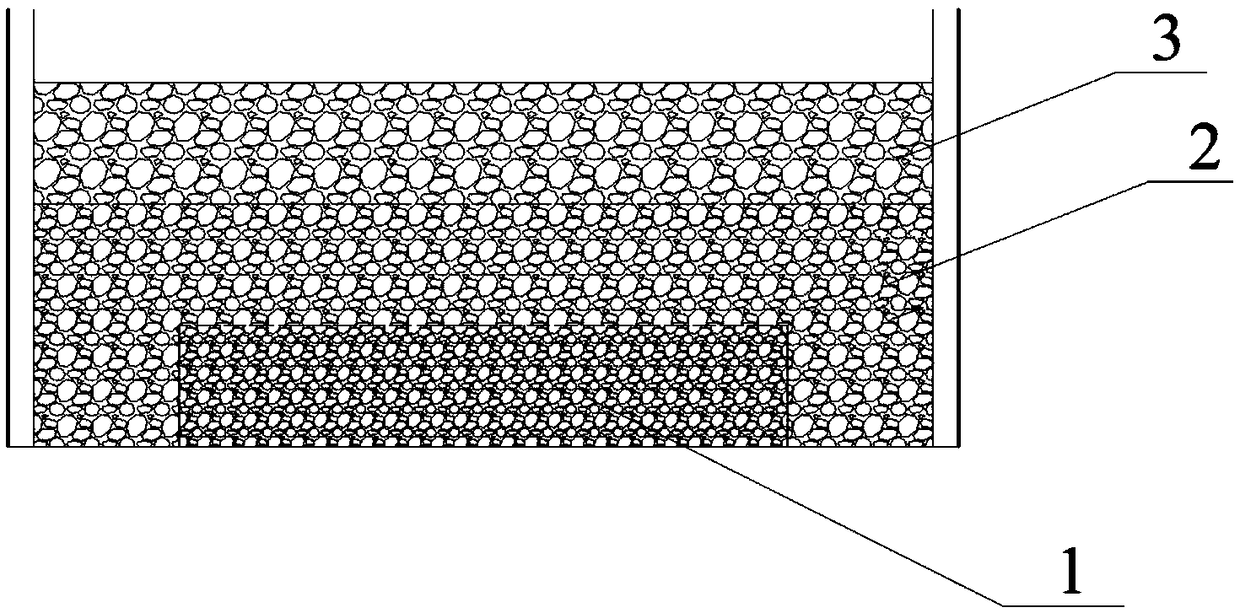

Image

Examples

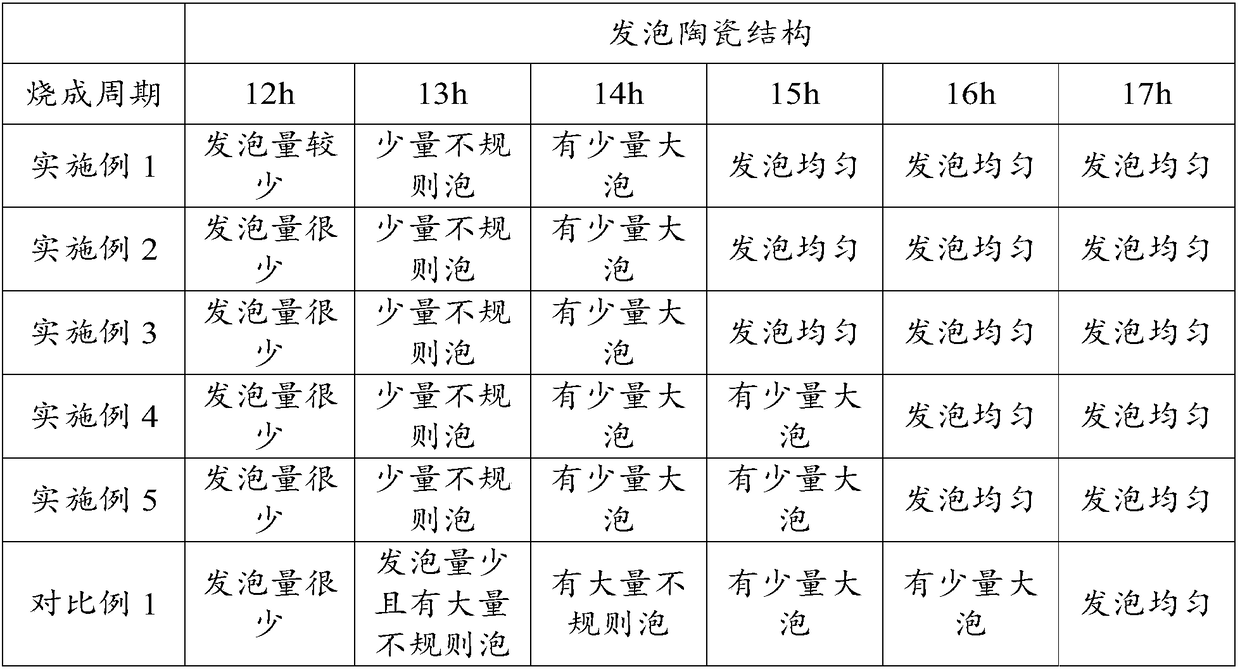

Embodiment 1

[0049] This embodiment provides a process for producing foamed ceramics from layered and partitioned fabrics, which includes:

[0050] S1. Configure ceramic raw materials.

[0051] Wherein, in parts by weight, the ceramic raw materials include:

[0052] 60 parts of polishing slag, 20 parts of pressing mud, 5 parts of waste glass, 6 parts of potassium feldspar, 4 parts of talc, 5 parts of medium temperature sand, and 0.1 part of sodium carboxymethyl cellulose.

[0053] S2. Preparation of pellets

[0054] Take the above-mentioned ceramic raw material, mix it with 0.5wt% silicon carbide, ball mill, spray granulate, and then roller granulate to make the first granular material whose particle size is -60~+80 mesh sieve; take the above-mentioned ceramic raw material, mix Add 0.3wt% of silicon carbide to make the second granular material with a particle size of -40 ~ +60 mesh sieve; take the above ceramic raw material, add 0.2wt% of silicon carbide, and make it through double-rolle...

Embodiment 2

[0063] This embodiment provides a process for producing foamed ceramics from layered and partitioned fabrics, which includes:

[0064] S1. Configure ceramic raw materials.

[0065] Wherein, in parts by weight, the ceramic raw materials include:

[0066] 30 parts of polishing slag, 40 parts of pressing mud, 5 parts of waste glass, 9 parts of potassium feldspar, 6 parts of talc, 15 parts of medium temperature sand, and 0.1 part of sodium carboxymethyl cellulose.

[0067] S2. Preparation of pellets

[0068] Take the above-mentioned ceramic raw material, mix it with 0.5wt% silicon carbide, ball mill, spray granulate, and then roller granulate to make the first granular material whose particle size is -60~+80 mesh sieve; take the above-mentioned ceramic raw material, mix Add 0.3wt% of silicon carbide, through roller granulation to make the second granular material whose particle size is -40~+60 mesh sieve; take the above ceramic raw material, add 0.2wt% of silicon carbide, throug...

Embodiment 3

[0077] This embodiment provides a process for producing foamed ceramics from layered and partitioned fabrics, which includes:

[0078] S1. Configure ceramic raw materials.

[0079] Wherein, in parts by weight, the ceramic raw materials include:

[0080] 35 parts of polishing slag, 20 parts of pressing mud, 15 parts of waste glass, 12 parts of potassium feldspar, 9 parts of talc, 11 parts of medium temperature sand, and 0.1 part of sodium carboxymethyl cellulose.

[0081] S2. Preparation of pellets

[0082] Take the above-mentioned ceramic raw material, mix it with 0.5wt% silicon carbide, ball mill, spray granulate, and then roller granulate to make the first granular material whose particle size is -60~+80 mesh sieve; take the above-mentioned ceramic raw material, mix Add 0.3wt% of silicon carbide, through roller granulation to make the second granular material whose particle size is -40~+60 mesh sieve; take the above ceramic raw material, add 0.2wt% of silicon carbide, thro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com