Vapor sealing box for printing and dyeing

A steam-sealing box and box body technology, which is applied in the direction of processing textile material containers, etc., can solve the problems of color fixing liquid waste, steam leakage, and large steam consumption, so as to reduce steam consumption, sufficient color fixing time, and improve product quality. quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

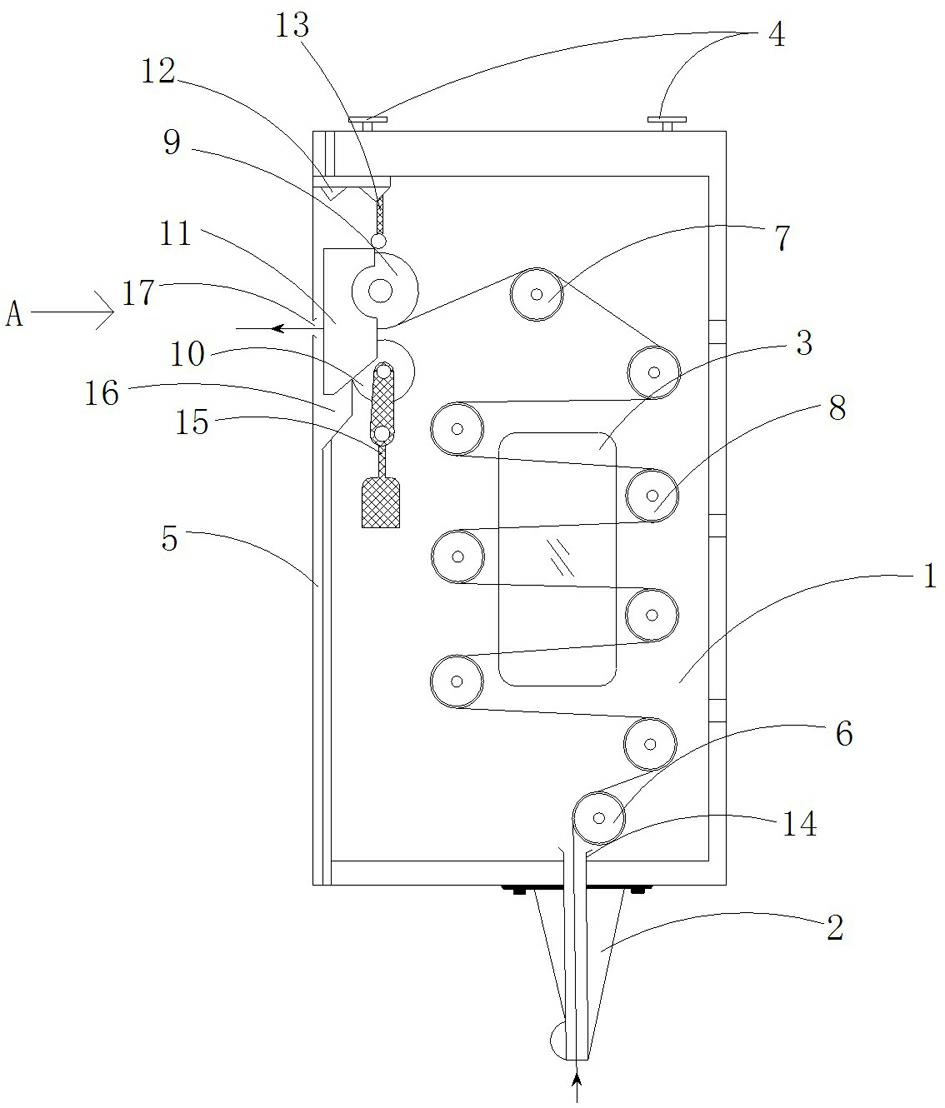

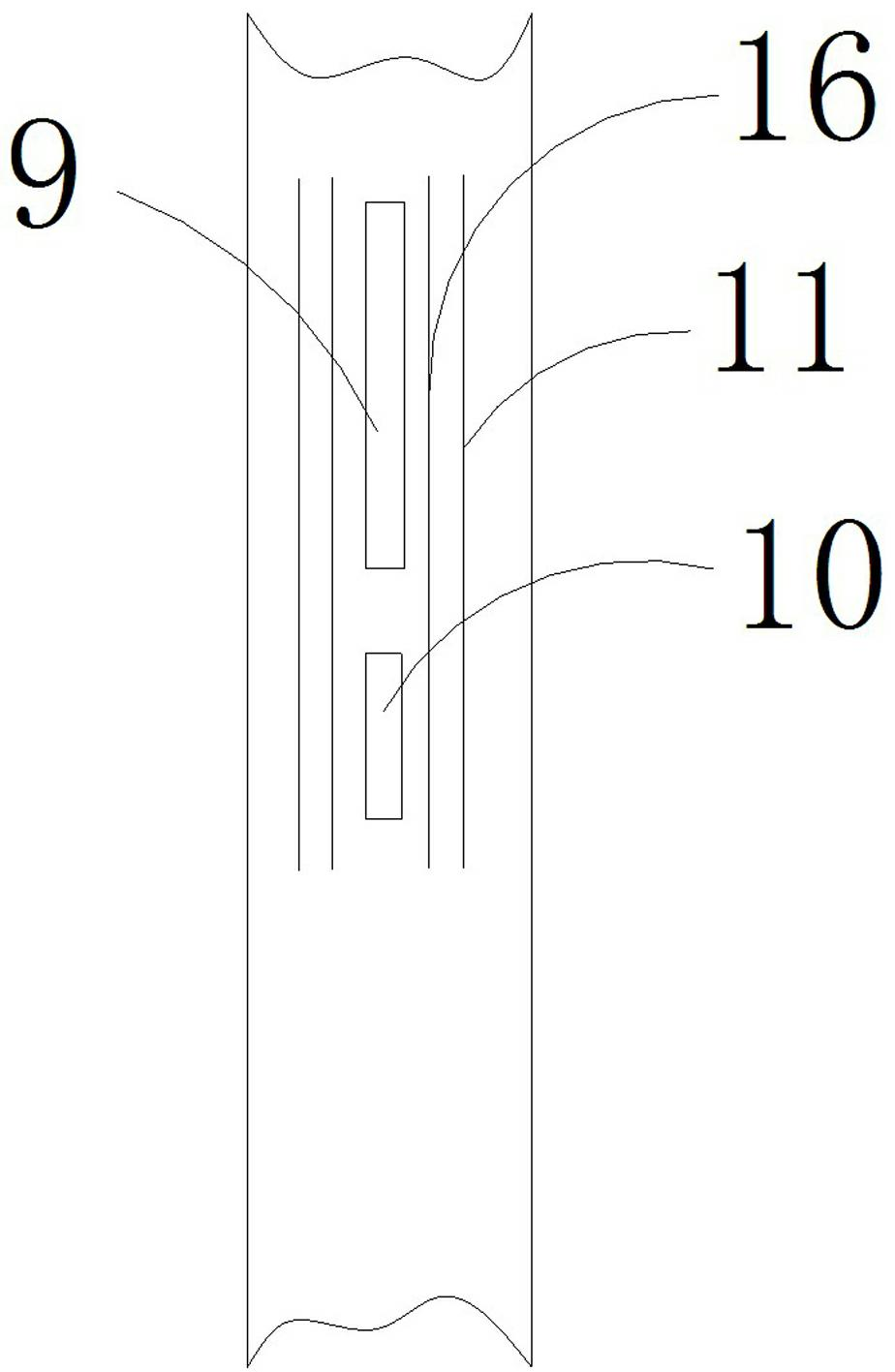

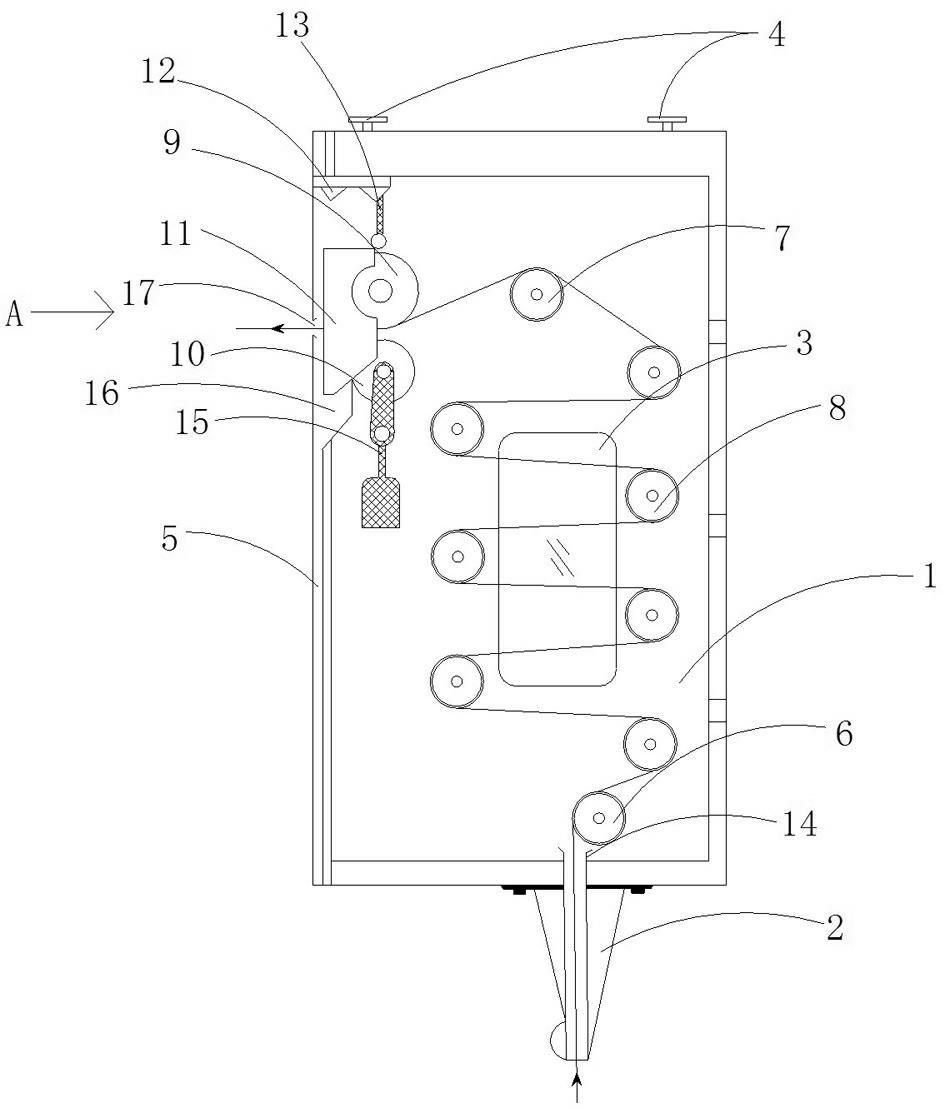

[0013] Embodiment 1: as figure 1 and figure 2 As shown, a steam sealing box for printing and dyeing includes a box body 1, the bottom side wall of the box body 1 is provided with a cloth inlet 2, the box body 1 is provided with a manhole door 3, and the box body 1 is provided with a manhole door 3. The upper part of the box body 1 is provided with two steam inlets 4, the side wall of the box body 1 is provided with a connecting flange 5, and the box body 1 is provided with a cloth guide mechanism and a steam leakage prevention heat preservation mechanism. The cloth guide mechanism includes a lower cloth guide roller 6, an upper cloth guide roller 7 and a cloth guide roller group 8, the lower cloth guide roller 6 corresponds to the cloth inlet 2, and the cloth guide roller group 8 is formed by the cloth guide roller Roller dislocation distribution, the upper cloth guide roller 7 is arranged above the cloth guide roller group 8; the steam leakage prevention and heat preservati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com