Upconversion fluorescent ink for inkjet printer and preparation method of upconversion fluorescent ink

An inkjet printer, fluorescent ink technology, applied in inks, applications, household appliances, etc., can solve the problems of short fixation time, unfavorable long-term storage of encrypted files, and inability to realize instant anti-counterfeiting printing, etc. Strong design, good anti-counterfeiting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment one: preparation ytterbium erbium co-doped sodium fluoride yttrium (NaYF 4 :Yb,Er) nanoparticles

[0036] 0.8mmol YCl 3 , 0.18mmol YbCl 3 , 0.02mmol ErCl 3 Dissolve in 2mL ultrapure water, then add dropwise to 25mL oleic acid / octadecene mixed solvent with a volume ratio of 1:2, stir for 30 minutes, heat to 160°C to remove the moisture in the solvent, and then cool to room temperature; 2.5mmol NaOH, 4mmol NH 4 F was dissolved in 5 mL of methanol, then added dropwise to the above oleic acid / octadecene mixed solvent, stirred for 2 hours, heated to 120°C to remove methanol in the solvent; then heated to 290°C, and kept for 1.5 hours to obtain ytterbium Erbium-codoped sodium yttrium fluoride (NaYF 4 : Yb, Er) nanoparticles, wherein the molar content of ytterbium (Yb) is 18%, and the molar content of erbium (Er) is 2%, which is green under the irradiation of 980nm wavelength laser.

Embodiment 2

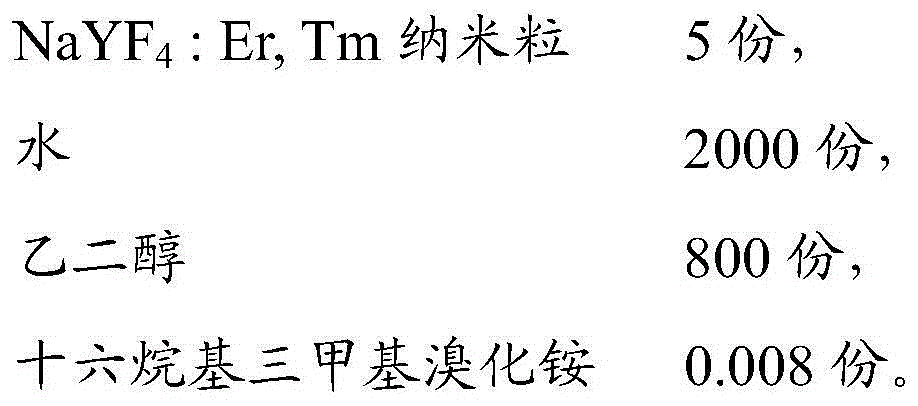

[0037] Embodiment two: preparation ytterbium thulium co-doped sodium fluoride yttrium (NaYF 4 :Yb,Tm) nanoparticles

[0038] 0.795mmol YCl 3 , 0.2mmol YbCl 3 , 0.005 mmol TmCl 3 Dissolve in 2mL ultrapure water, then add dropwise to 25mL oleylamine / octadecene mixed solvent with a volume ratio of 1:2, stir for 30 minutes, heat to 160°C to remove the water in the solvent, and then cool down to room temperature; 2.5mmol NaOH, 4mmolNH 4 F was dissolved in 5mL of methanol, then added dropwise to the above mixed solvent of oleylamine / octadecene, stirred for 2 hours, heated to 120°C to remove methanol in the solvent; then heated to 290°C, and kept for 1.5 hours to obtain ytterbium Thulium-codoped sodium yttrium fluoride (NaYF 4 : Yb, Tm) nanoparticles, wherein the molar content of ytterbium (Yb) is 20%, and the molar content of thulium (Tm) is 0.5%, which is blue under the irradiation of 980nm wavelength laser.

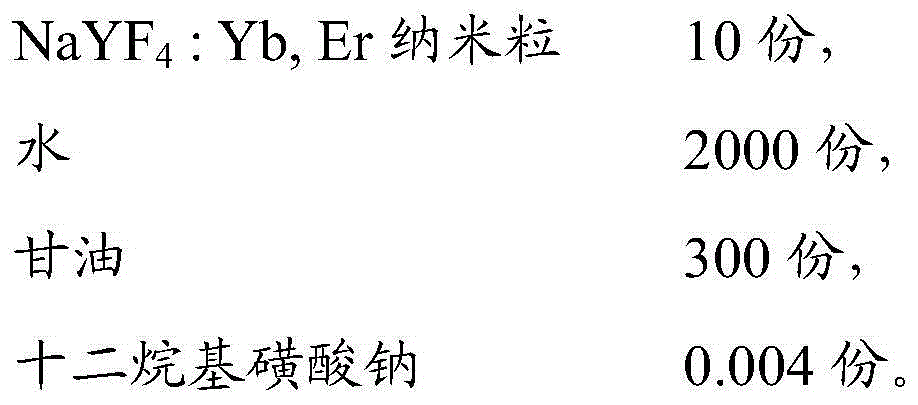

Embodiment 3

[0039] Embodiment three: prepare the sodium yttrium fluoride (NaYF 4 :Er,Tm) nanoparticles

[0040] 0.88mmol YCl 3 , 0.1mmol ErCl 3 , 0.02mmol TmCl 3 Dissolve in 2mL ultrapure water, then add dropwise to 25mL oleic acid / oleylamine / octadecene mixed solvent with a volume ratio of 1:1:2, stir for 30 minutes, heat to 160°C to remove the moisture in the solvent, and then Cool down to room temperature; 2.5mmol NaOH, 4mmol NH 4 F was dissolved in 5mL of methanol, and then added dropwise to the above mixed solvent of oleic acid / oleylamine / octadecene, stirred for 2 hours, heated to 120°C to remove methanol in the solvent; then heated to 290°C, and kept for 1.5 hours, Erbium-thulium co-doped sodium yttrium fluoride (NaYF 4 : Er, Tm) nanoparticles, wherein, the molar content of erbium (Er) is 10%, and the molar content of thulium (Tm) is 2%, which is red under the irradiation of 980nm wavelength laser.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

| Dynamic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com