Preparation method of ultraviolet-proof anti-electromagnetic radiation textile fabric

An anti-electromagnetic radiation and anti-ultraviolet technology is applied in the field of textile product manufacturing to achieve the effects of high output, simple production process and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] A specific embodiment of the preparation method of a kind of anti-ultraviolet and anti-electromagnetic radiation textile fabric of the present invention, comprising

[0021] Sequential screening agent mixing process, padding process and high temperature fixing process;

[0022] The shielding agent mixing process: add the PEDOT / PSS aqueous dispersion to the water-soluble polyurethane solution after shaking and dispersing, and stir the mixed solution fully; the weight percentage of the raw materials is: 30% to 60% of the PEDOT / PSS aqueous dispersion, water-soluble 40% to 70% of non-toxic polyurethane solution;

[0023] The padding process: the PEDOT / PSS solution is placed in the dipping tank of the padding machine, the fabric base cloth is subjected to two dipping and two rolling processes at room temperature, and the PEDOT / PSS mixed aqueous solution is padded onto the fabric; wherein, each The excess rate of similar fabrics is 60% to 80%;

[0024] The high-temperature ...

Embodiment 1

[0026] Embodiment 1: a kind of preparation method of anti-ultraviolet and anti-electromagnetic radiation textile fabric, comprises the following steps:

[0027] (1) Screening agent mixing process: After shaking and dispersing the PEDOT / PSS aqueous dispersion, add it to the water-soluble polyurethane solution, and stir the mixed solution thoroughly; the weight percentage of the raw materials is: PEDOT / PSS aqueous dispersion 40%, water-soluble polyurethane The solution is 60%; among them, the solid content of PEDOT / PSS in the PEDOT / PSS aqueous dispersion is 1.5%, and the solid content of polyurethane in the water-soluble polyurethane solution is 60%.

[0028] (2) Padding process: PEDOT / PSS solution is placed in the immersion tank of the padding machine, and the pure cotton fabric is used as the base fabric to go through the second dipping and second rolling process at room temperature, and the PEDOT / PSS mixed aqueous solution is padded to the pure cotton fabric above; among them...

Embodiment 2

[0031] Embodiment 2: a kind of preparation method of anti-ultraviolet and anti-electromagnetic radiation textile fabric, comprises the following steps:

[0032] (1) Screening agent mixing process: After shaking and dispersing the PEDOT / PSS aqueous dispersion, add it to the water-soluble polyurethane solution, and stir the mixed solution thoroughly; the weight percentage of the raw materials is: PEDOT / PSS aqueous dispersion 50%, water-soluble polyurethane The solution is 50%; wherein, the solid content of PEDOT / PSS in the PEDOT / PSS aqueous dispersion is 2%, and the solid content of polyurethane in the water-soluble polyurethane solution is 50%.

[0033] (2) Padding process: PEDOT / PSS solution is placed in the immersion tank of the padding machine, and the polyester fabric is used as the base fabric to go through the second dipping and second rolling process at room temperature, and the PEDOT / PSS mixed aqueous solution is padded onto the pure cotton fabric. ; Among them, the exc...

PUM

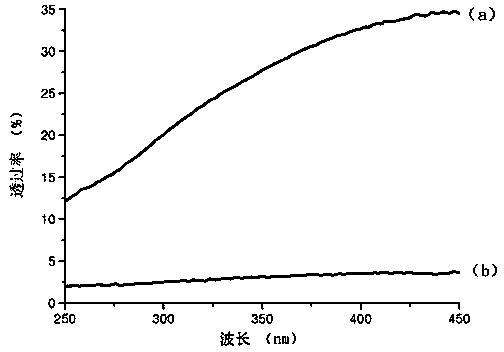

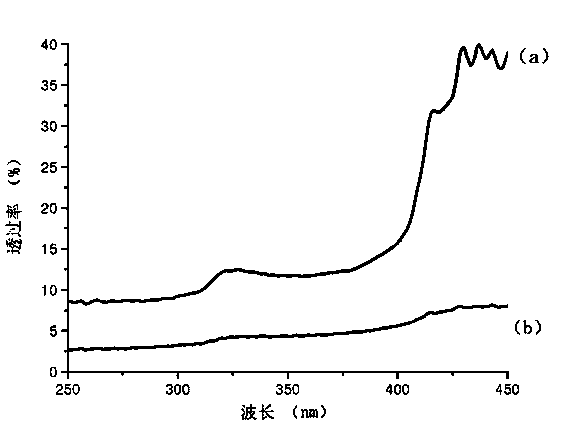

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com