Laser positioning device

A technology for laser positioning and measuring beams, which is applied in measuring devices, re-radiation of electromagnetic waves, and utilization of re-radiation, etc. It can solve problems such as tediousness, poor user experience, and large errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

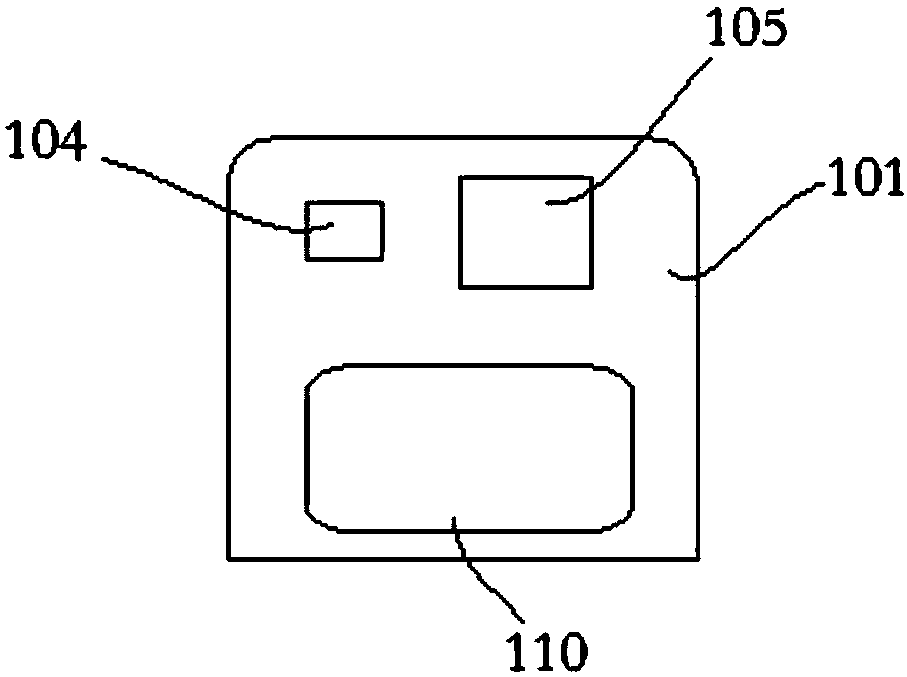

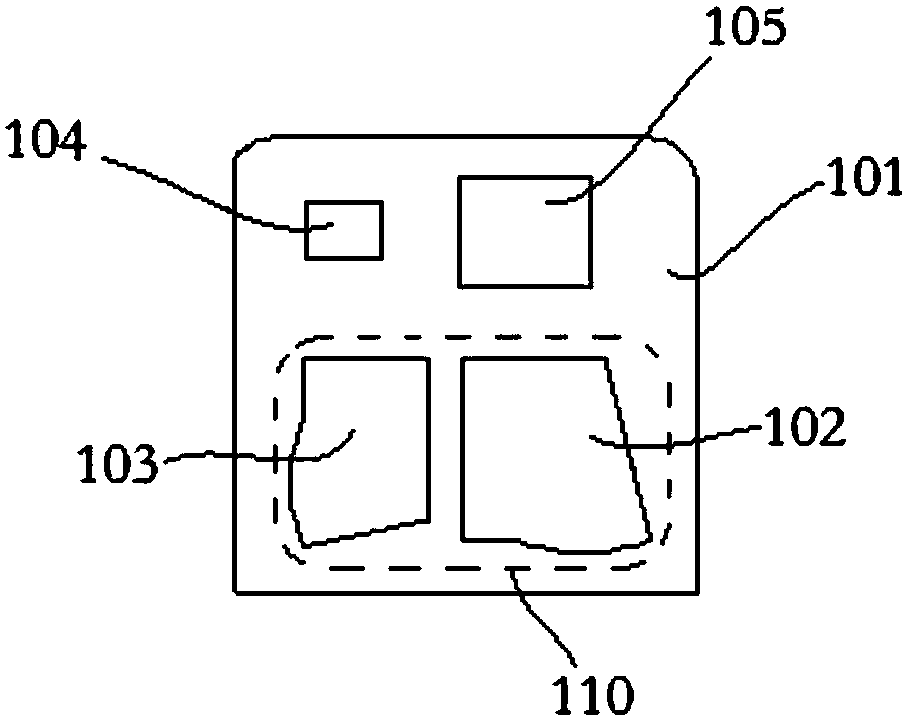

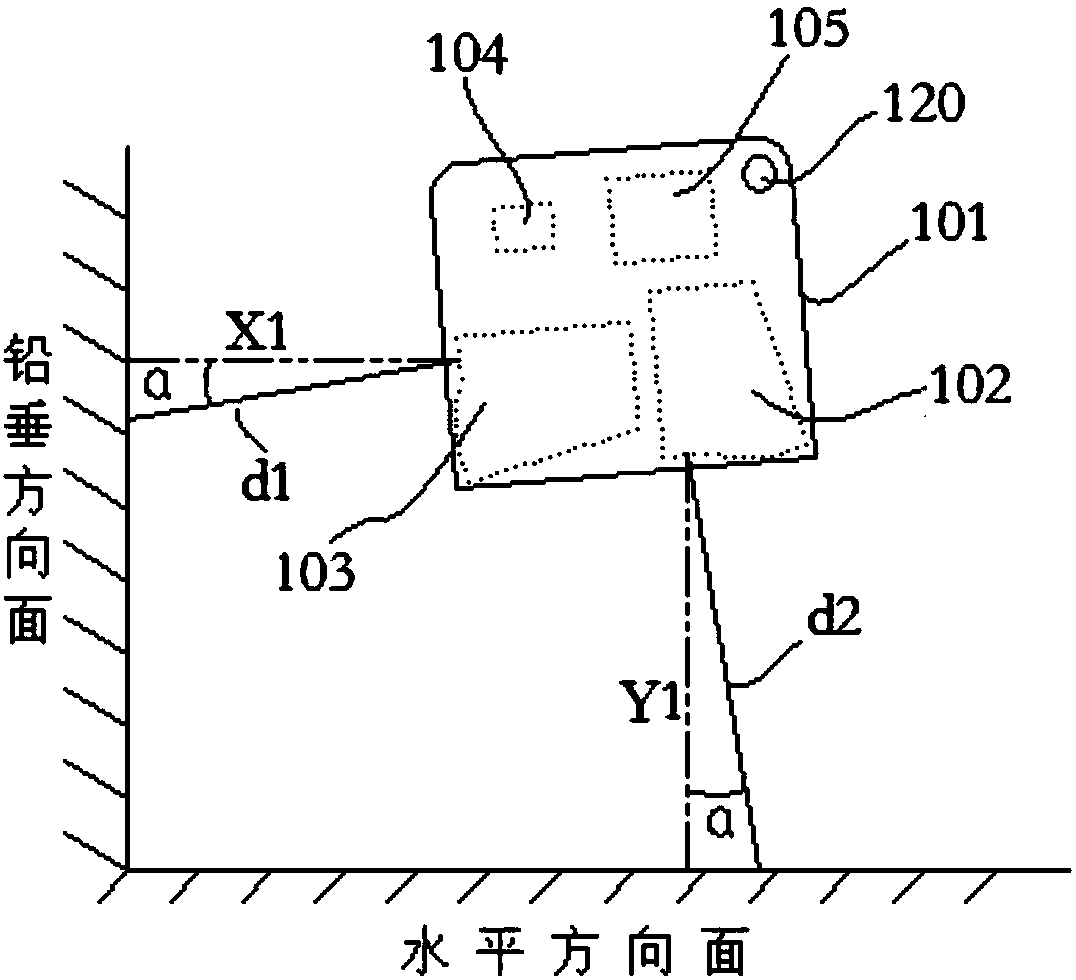

[0025] according to figure 2 , image 3 Embodiment 1 of the present embodiment shown, in this embodiment, the laser positioning device 101 includes a ranging unit 110, an acceleration sensing unit 104, and a control unit 105; wherein, the ranging unit 110 includes a first A ranging module 102 and a second ranging module 103 . In this embodiment, the first ranging module 102 is used to emit and receive the first measuring beam on the horizontal plane in the target space, so as to measure the distance to the actual irradiation point on the horizontal plane; the second ranging module 103 The second measuring light beam is used to transmit and receive the second measuring beam on the vertical plane in the target space, so as to measure the distance to the actual irradiated point on the vertical plane. In addition, in this embodiment, the included angle between the first measuring beam and the second measuring beam is set as a fixed angle.

[0026] Such as figure 2 , image ...

Embodiment 2

[0031]In this embodiment, the laser positioning device 101 includes a ranging unit 110, an acceleration sensing unit 104, and a control unit 105; wherein, the ranging unit 110 includes a laser emitting module, a light splitting module, and a laser receiving and measuring module (attached Not shown in the figure) the laser emitting module and the laser receiving and measuring module.

[0032] The specific working principle of embodiment 2 is as follows:

[0033] Place the laser positioning device 101 in a substantially horizontal or substantially vertical state in the target space, the laser emitting module of the distance measuring unit 110 emits a beam, and the beam splitting module divides the beam emitted by the laser emitting module into the first horizontal plane in the target space. The measurement beam and the second measurement beam to the vertical direction plane in the target space, the laser receiving and measuring module receives the first measurement beam and the ...

Embodiment 3

[0036] In this embodiment, the laser positioning device 101 includes a ranging unit 110, an acceleration sensing unit 104, and a control unit 105; wherein, the ranging unit 110 includes a laser transceiver measurement module, a spectroscopic module (both in the drawings Not shown) laser transceiver measurement module.

[0037] The specific working principle of embodiment 3 is as follows:

[0038] Place the laser positioning device 101 in a substantially horizontal or substantially vertical state in the target space, the laser transceiver and measurement module of the distance measuring unit 110 emits light beams, and the beam splitting module divides the beam emitted by the laser transceiver and measurement module into horizontal planes in the target space. The first measurement beam and the second measurement beam to the vertical direction plane in the target space, the laser transceiver measurement module receives the first measurement beam and the second measurement beam to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com