Relay type rapid chip taking and chip assembling device and chip assembling machine employing same

A technology of loading and driving devices, which is applied to conveyor objects, transportation and packaging, electrical components, etc., can solve the problems of long packaging time, large rotation stroke, low production efficiency, etc., and achieve high packaging accuracy and efficiency. The effect of improving and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

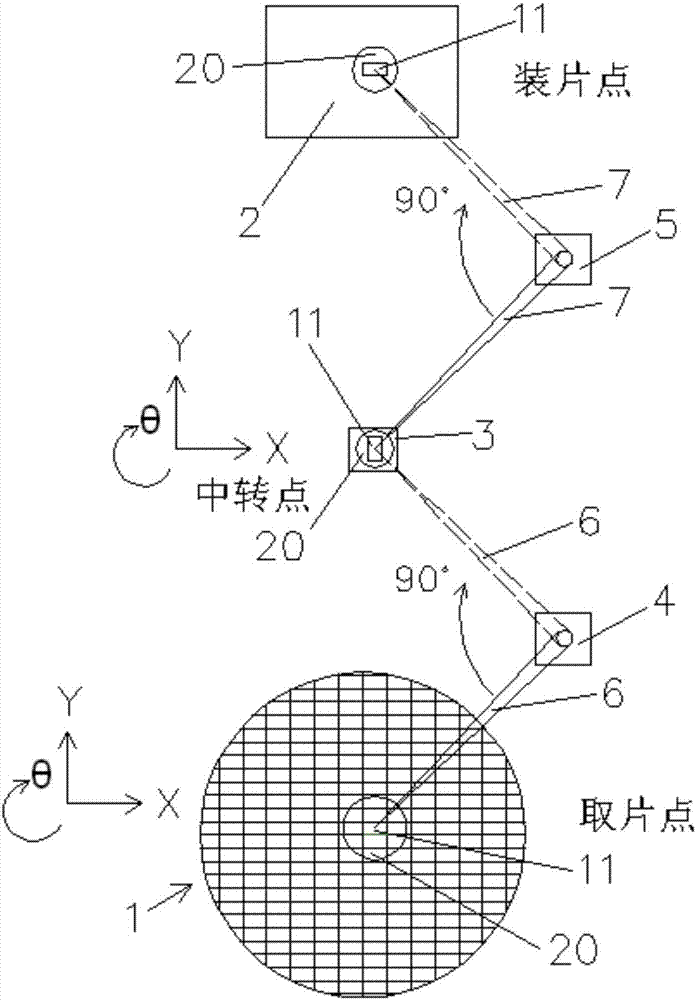

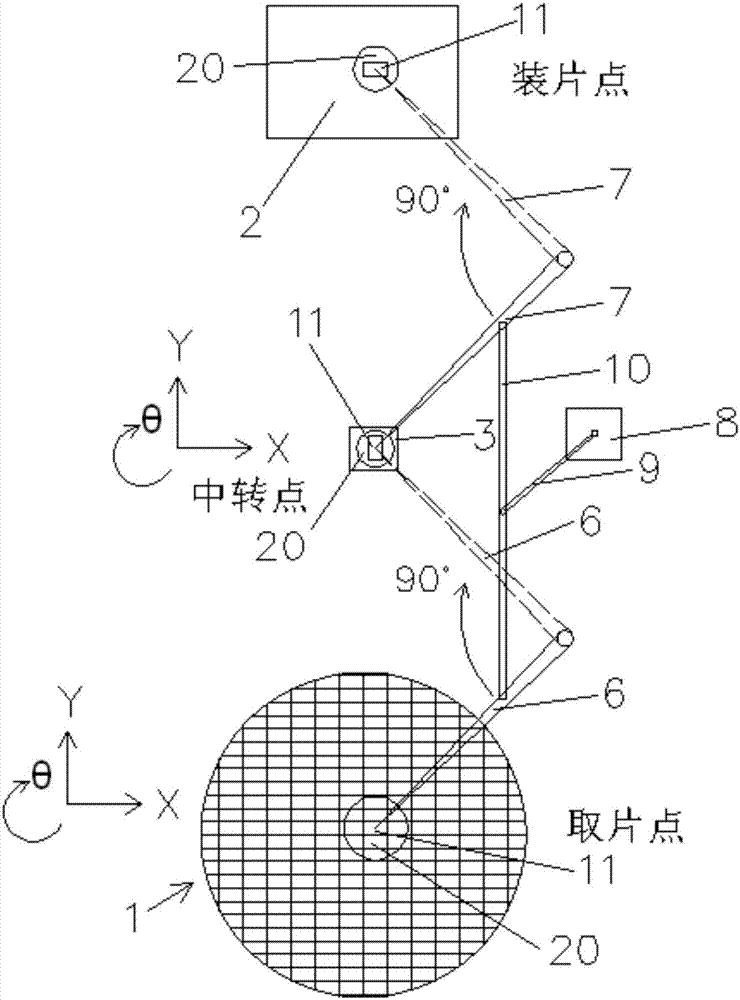

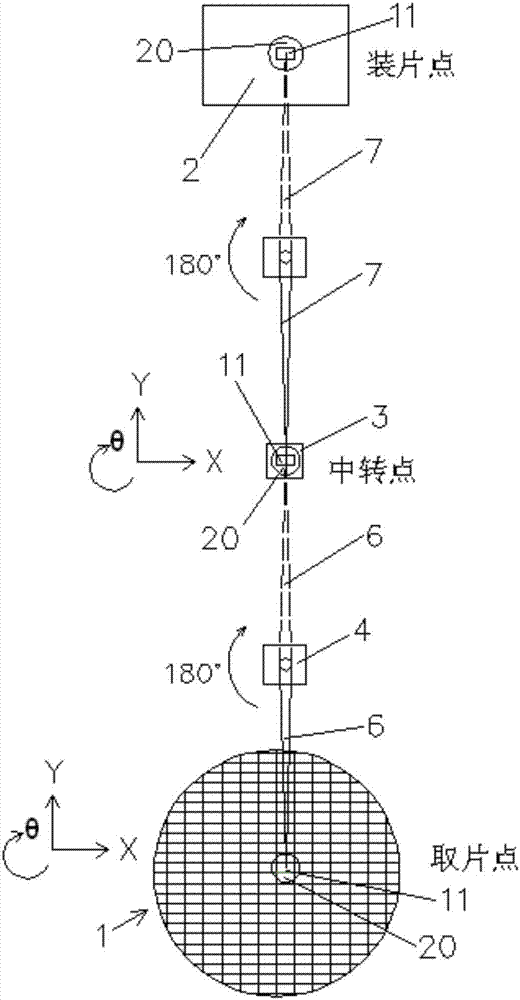

[0038] In order to achieve the purpose of the present invention, as shown in the figure, one embodiment of the present invention is: a relay-type fast chip picking and loading device, including a wafer table 1, and the wafer table 1 is used to place wafers, including: The first rotating arm 6, the first rotating arm 6 is used to take out the chip 11 on the wafer, and after rotation, the chip 11 is placed on the following transfer table 3; the transfer table 3 is used for the transfer of the chip; the second rotating arm 7, The second rotating arm 7 is used to take out the chip 11 on the turntable 3, and the chip 11 is placed on the substrate 2 after rotation; the welding head is used to take out the chip 11 and place the chip 11, and the welding head is arranged on the first rotating arm 6 and One end of the second rotating arm 7, the welding head moves back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com