Welding visual detection method and device based on convolutional neural network

A convolutional neural network and visual detection technology, applied in the field of crawlers, can solve problems such as the difficulty of explicit feature extraction and the inability to guarantee accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] The present invention will be further described below in conjunction with the accompanying drawings.

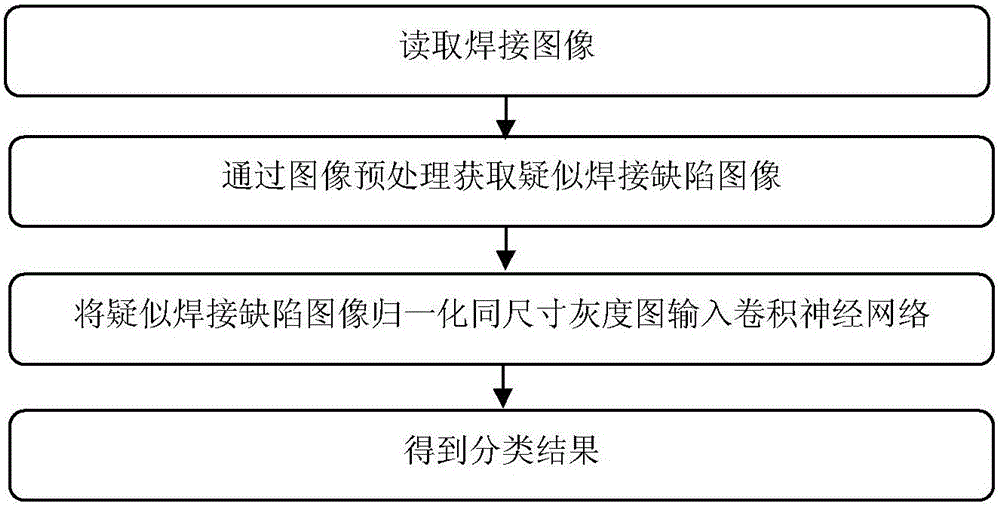

[0075] refer to Figure 1 to Figure 7 , a welding visual detection method based on convolutional neural network, including the following process:

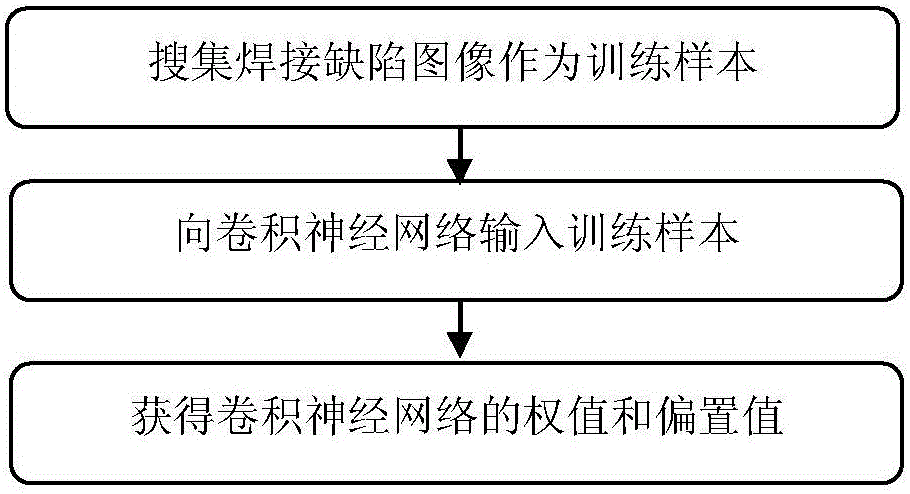

[0076] In the training phase, it is first necessary to collect training samples. In this embodiment, a total of 10,000 training samples are collected. Among the 10,000 samples, 500 are welding defect pictures, and the remaining 9500 are the aforementioned 500 welding defect pictures. Welding defect pictures obtained by adding Gaussian white noise, picture rotation, color transformation, translation, contrast stretching, flipping and other image processing methods. Then these samples are input into the convolutional neural network for training, and the connection weights and bias values of the convolutional neural network are obtained.

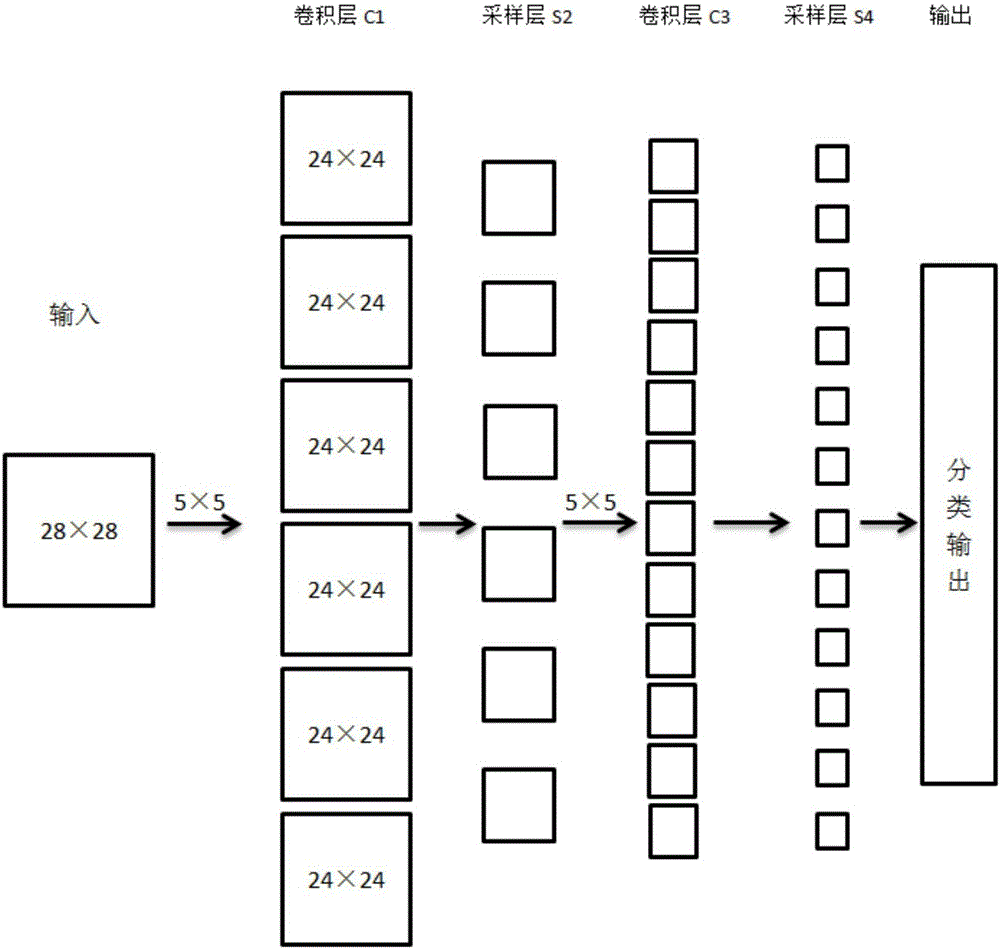

[0077] In this embodiment, the structure of the convolutional neural network adopts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com