Polar coordinate composite camera rack for vision inspection

A technology of visual inspection and polar coordinates, which is applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems of difficult to obtain images, difficult to adjust the camera position, etc., and achieve the effect of convenient disassembly and easy measurement of angle parameters

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in detail below in combination with specific embodiments.

[0015] The camera frame of the present invention is a mechanical mechanism used for installation, positioning and position adjustment of industrial cameras used in image acquisition in an industrial detection system.

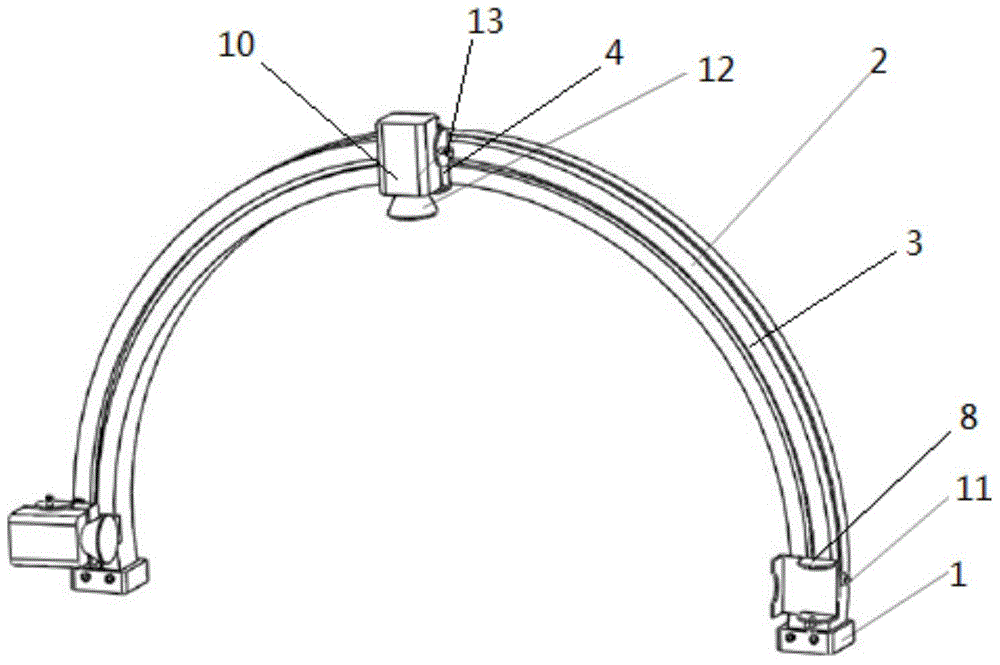

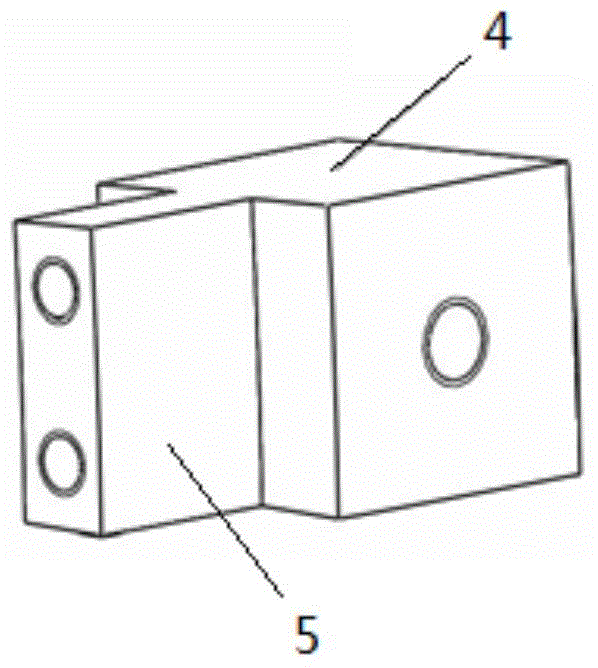

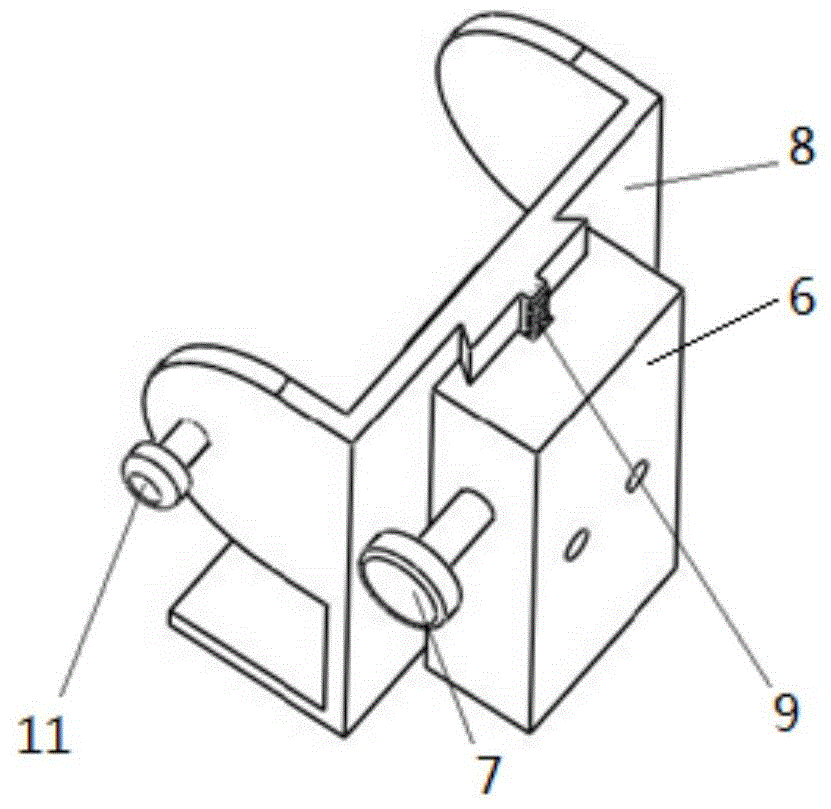

[0016] The camera frame system of the present invention includes an end cover 1 and an arc frame 2, two end caps 1 are installed on the two ends of the arc frame 2 respectively, and the end cover 1 is fixed on the work surface to support the entire arc. The role of shaped rack 2. The arc frame 2 is provided with a guide rail 3, and the slider 4 is installed in the guide rail 3. The slider 4 can slide on the arc frame 2 along the guide rail 3. The bracket fine-tuning device is fixedly connected with the slider 4, and the bracket fine-tuning device It is connected with the camera fixing bracket, and the bracket fine-tuning device adjusts the position of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com