Visual automatic thread inspection device and using method

An automatic detection device and thread technology, applied in the direction of measuring devices, mechanical measuring devices, mechanical devices, etc., can solve the problems that the measurement results are easily affected by human factors, cannot meet actual needs, and lack the basis for qualified judgments, etc., to achieve quality The effect of automatic detection, reduction of enterprise cost and labor intensity, and reliable detection results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

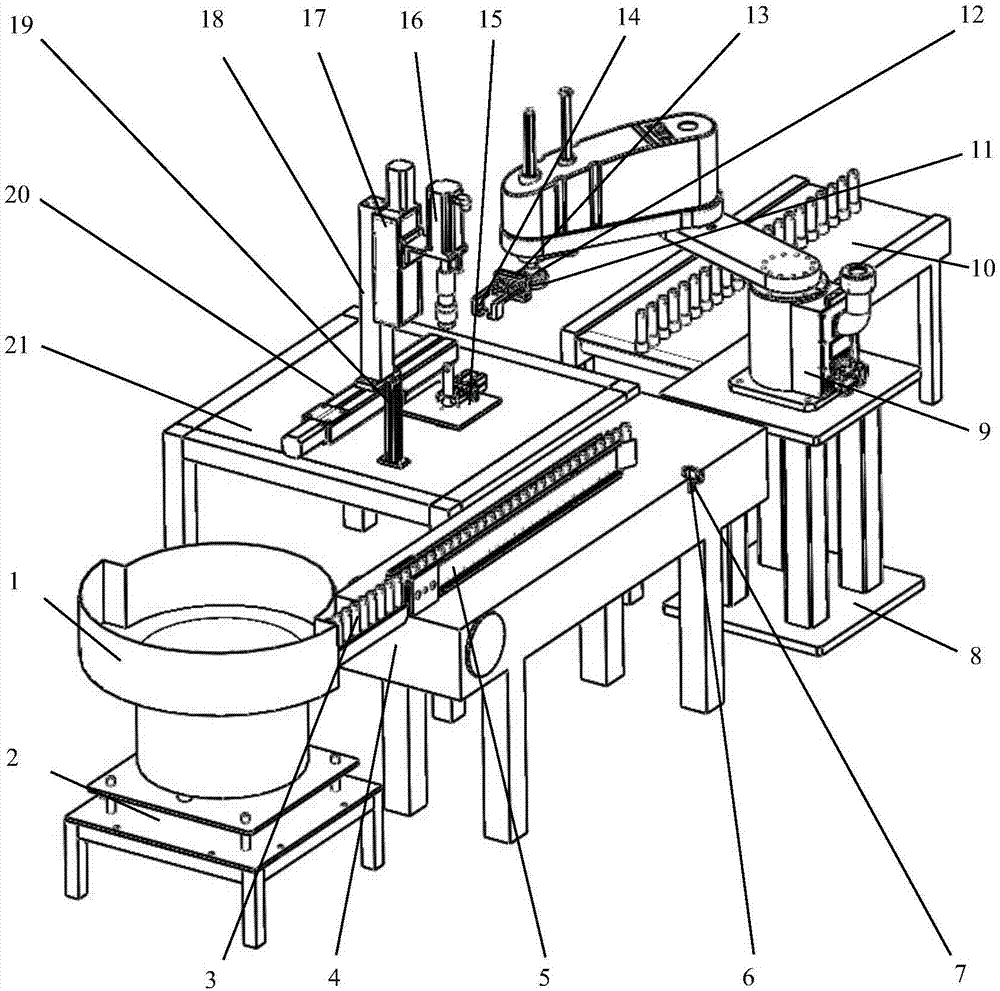

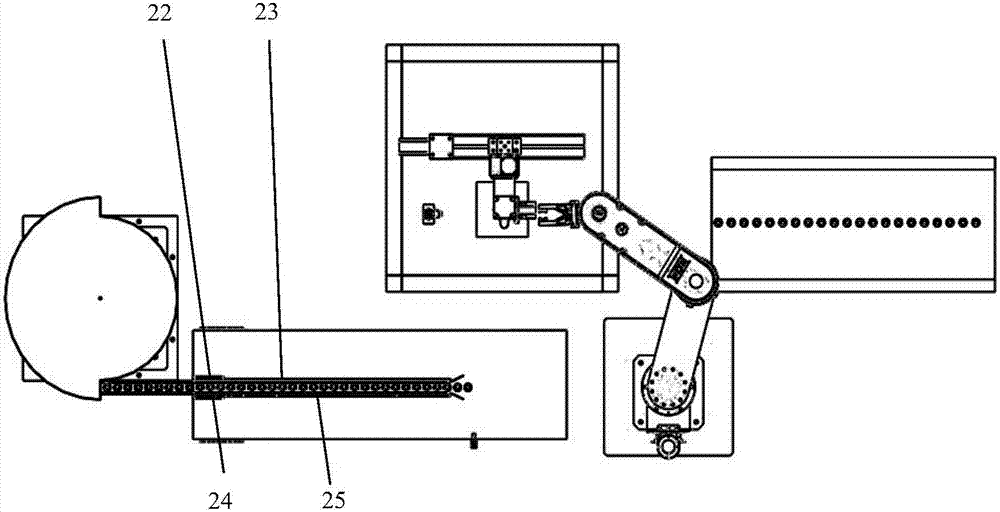

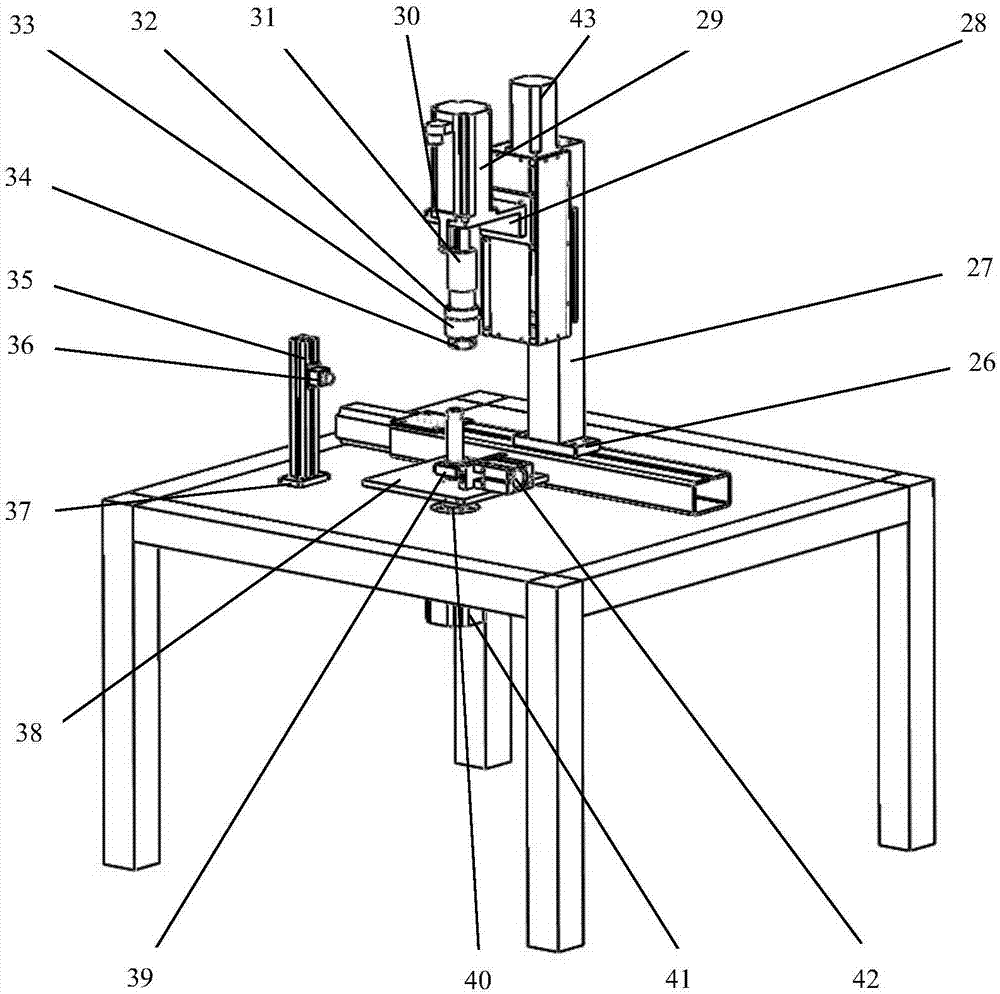

[0017] Such as figure 1 , figure 2 , image 3 , Figure 4As shown, a thread automatic detection device with vision and its use method are composed of a vibrating plate device, a first conveying line device, a robot device, a comprehensive inspection platform, and a second conveying line. The vibrating plate device includes a vibrating plate 1 and a vibrating plate mounting base 2, the vibrating plate 1 is fixedly mounted on the vibrating plate mounting base 2, and the vibrating plate mounting base 2 is fixedly mounted on the ground; the first conveying line device includes a first conveying line 4, a limited Positioning device 5, threaded workpiece 3, photoelectric sensor 6 and photoelectric sensor mounting plate 7, the first conveying line 4 is connected with the vibration plate 1, and is located on the same horizontal plane, the limiting device 5 includes the first conveying baffle plate 22, the first conveying installation plate 23, the second conveying baffle 24 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com