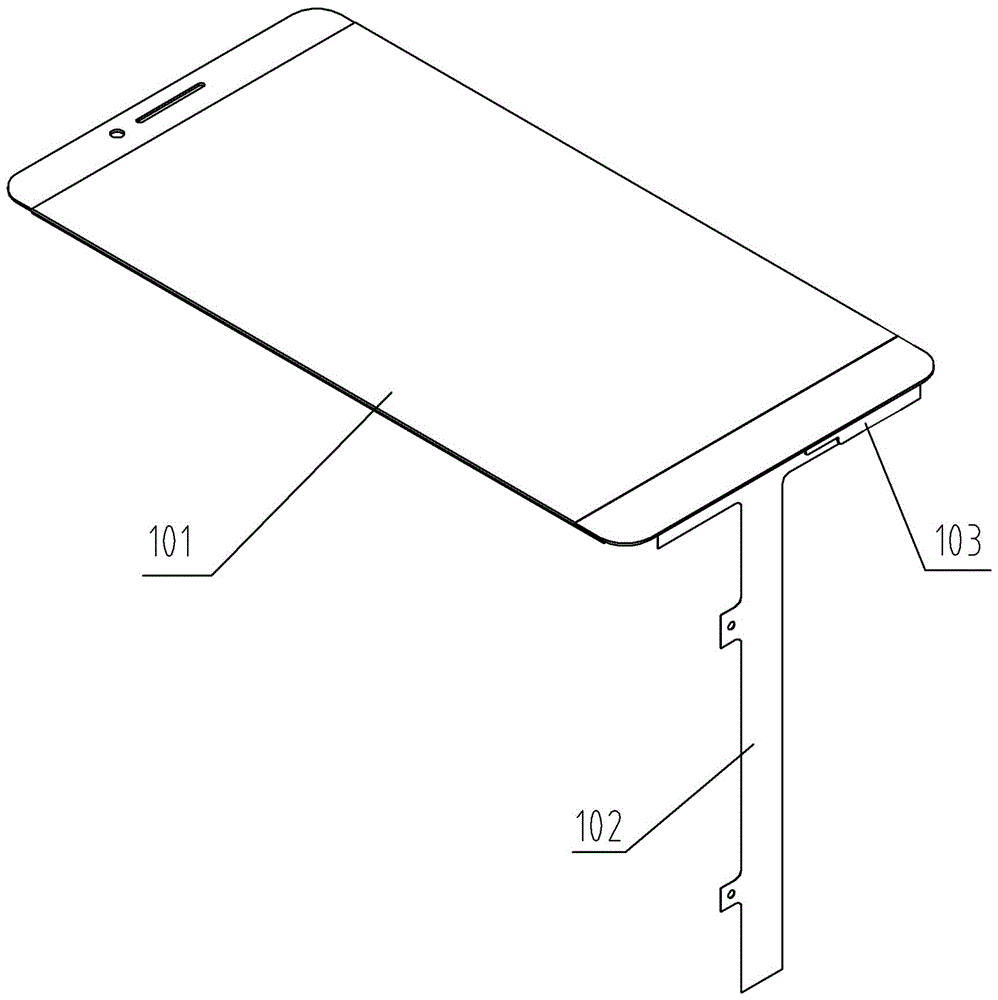

Mobile phone assembling machine

A technology for assembly machines and mobile phones, which is applied in assembly machines, metal processing equipment, manufacturing tools, etc., and can solve problems such as difficulty in realizing accurate work of automation equipment, small film area and thickness of circuit boards, and low production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

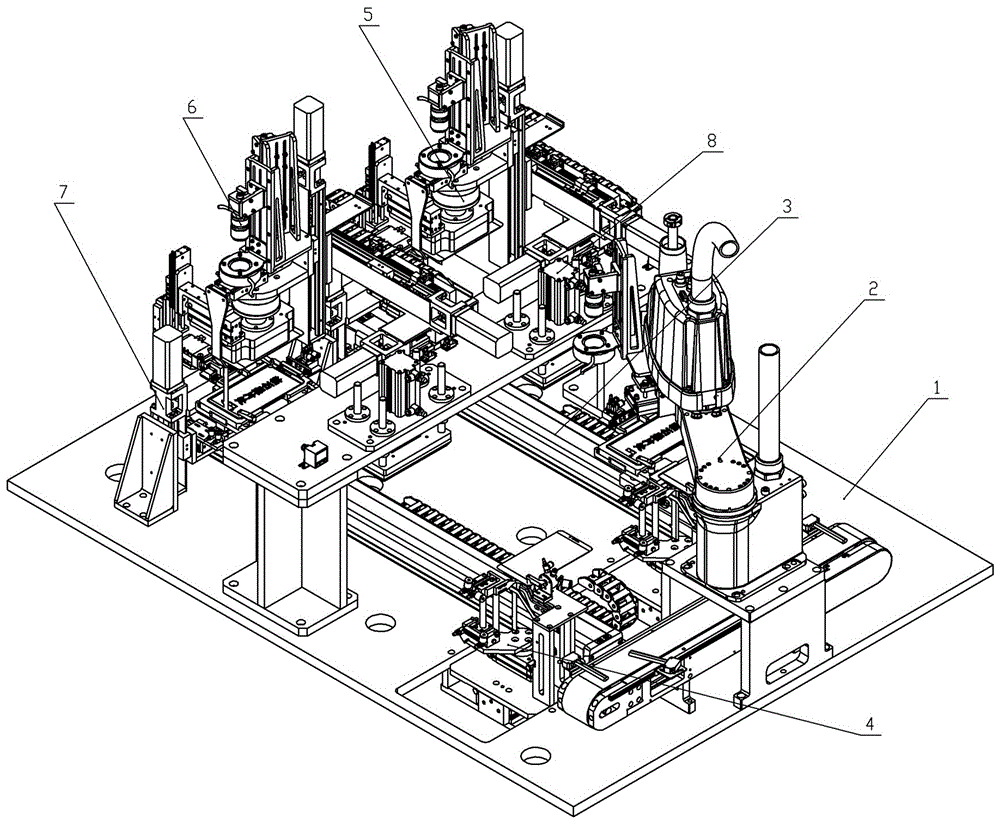

[0018] Such as figure 2 As shown, a mobile phone assembly machine includes a body bracket 1, on which are respectively installed loading and unloading components 2 for grabbing materials to the installation station or removing materials from the installation station, positioning the materials and sending them to different The feeding component 3 of the processing station, the FPC component 4 for processing the conductive film of the mobile phone screen, the assembly component 5 for assembling the mobile phone screen and the mobile phone case, and the pressure maintaining component 8 for maintaining the pressure and stability of the mobile phone.

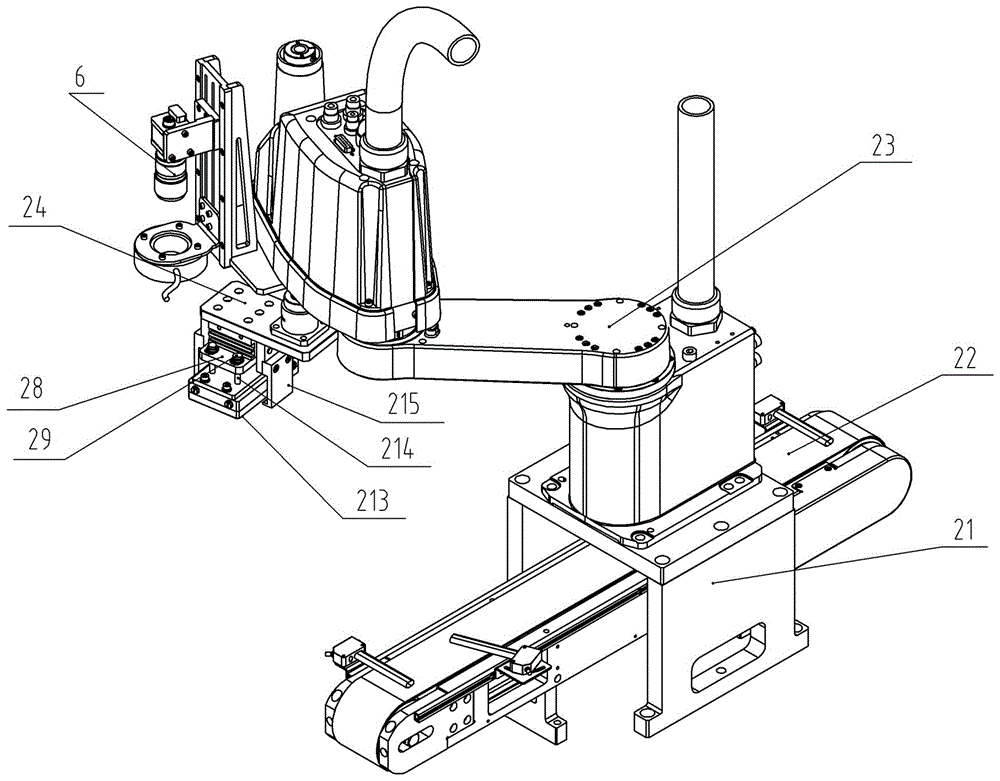

[0019] Such as image 3 , 4 As shown, the loading and unloading assembly 2 includes a base 21 fixedly installed on the body support 1, a movable manipulator 23, the manipulator is equipped with a gripper for grabbing materials and a gripper driver for driving the movement of the gripper; the bottom of the base 21 is provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com