Intelligent sensor self-correcting method

An intelligent sensor and self-calibration technology, applied in the field of decoupling self-calibration, can solve the problems of sensor compatibility and poor interchangeability, and achieve the effect of good applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to make the purpose, technical solution and advantages of the patent of the present invention clearer, the patent of the present invention will be further described in detail below in conjunction with the accompanying drawings.

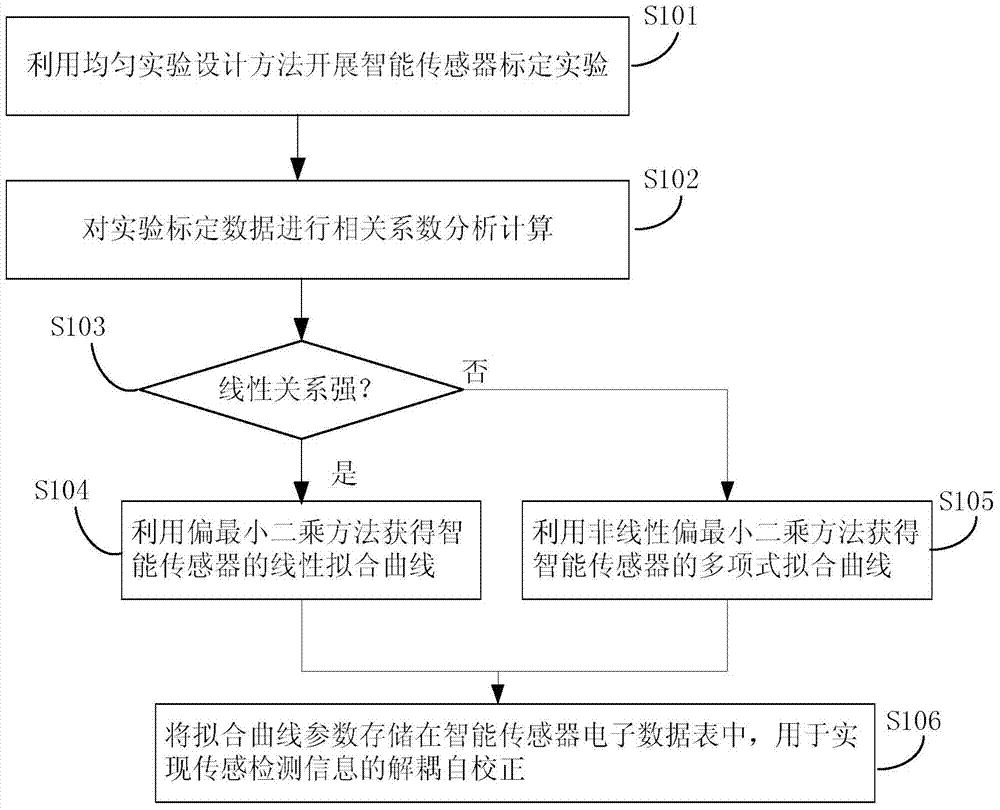

[0014] The invention provides an intelligent sensor self-calibration method, which uses a uniform experimental design method to carry out experimental calibration for the intelligent sensor; calculates the correlation coefficient between the independent variable and the dependent variable according to the experimental calibration data; calculates the correlation coefficient between the independent variable and the dependent variable according to the Correlation coefficient matrix, using the partial minimum multiplication regression method or nonlinear partial least multiplication regression method to model the smart sensor, and obtain the fitting curve of the smart sensor; use the obtained fitting curve to store the curve parameters in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com