Optical resolution type photoacoustic microscope based on optical beam scanning

A photoacoustic microscope and beam scanning technology, applied in the field of optical resolution photoacoustic microscope, can solve the problems of difficult miniaturization and portable design, large laser volume, difficult maintenance, etc., and achieve simple signal post-processing circuit, large imaging depth, easy maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

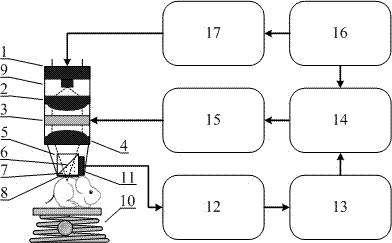

[0022] Embodiment 1 The structure of this embodiment is as follows figure 1 As shown, the names of the components are: 1. Laser diode, 2. Collimating lens, 3. Multi-dimensional laser galvanometer, 4. Focusing lens, 5. Right-angle prism, 6. Coupling liquid box, 7. Ultrasonic coupling liquid, 8. .Film, 9. Shell, 10. Lifting platform, 11. Ultrasonic sensor, 12. Signal preprocessing circuit, 13. Data acquisition circuit, 14. Computer, 15. Vibrating mirror driving circuit, 16. Clock circuit, 17. Driving power supply circuit.

[0023] Among them, the laser diode 1 is a pulsed semiconductor laser diode (PFAS1S12, PerkinElmer), the working wavelength is 850nm, and the single pulse energy is about 3.9uJ; the ultrasonic sensor 11 is a 256-element surface array probe with a hollow structure (5M16*16-1.0*1.0 , Guangzhou Doppler Electronic Technology Co., Ltd.), the center frequency is 5.0MHz, the effective aperture is 16mm, and the shell model is B16; the focusing lens 4 adopts an aspher...

Embodiment 2

[0037] Embodiment 2 An optical resolution photoacoustic microscope based on beam scanning, which is similar in structure to Embodiment 1, the difference is that the ultrasonic sensor 11 adopts a hollow unit angle probe (5.0 P9×9K1), the center frequency is 5.0MHz, the size is 9 mm×9 mm, and the external interface adopts Q9 (BNC) interface.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com