Method for restoring crack of blade of hydraulic turbine

A blade crack and repair method technology, applied in the field of metal parts repair, can solve the problems of reducing the service life of blades, material composition, complex structure, and affecting the bonding strength of welds, so as to prolong the service life, prevent weld defects, and improve welding The effect of seam bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

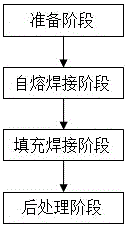

[0018] Such as Figure 1-4 As shown, a water turbine blade crack repair method of the present invention includes a preparation stage, a self-fluxing welding stage, a filling welding stage, and a post-processing stage.

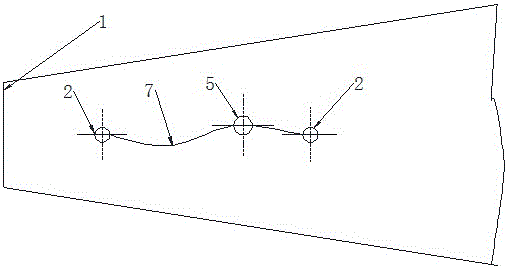

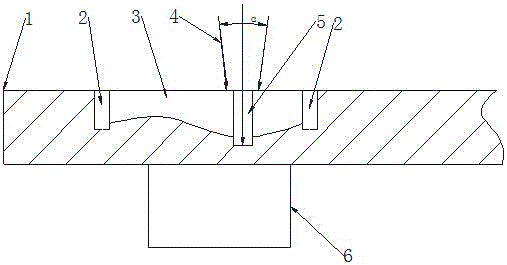

[0019] Among them, in the above preparation stage, the following steps are performed: 1) cleaning the blade 1 to be repaired, removing oil stains and sundries on the surface of the blade 1 and in the weld seam; The maximum depth and its position; 3) Make a truncated hole 2 at each end of the crack 7 with a diameter greater than 1-2 mm of the crack width and a depth of about 3 mm greater than the crack depth; 4) Make a hole 2 with a diameter greater than the crack width 1-2 mm at the maximum crack depth 2mm, and a detection hole 5 whose depth is about 3mm greater than the crack depth; 5) Fix an ultrasonic generator 6 on the back of the blade.

[0020] When the preparatory stage is completed, the crack self-fluxing welding is carried out, and the self-fluxing we...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com