Runner of opposite-rotating through flow turbine capable of bidirectionally generating electricity

A tubular water turbine and water turbine technology, applied in renewable energy power generation, hydropower generation, machines/engines, etc., can solve problems such as low efficiency and complex structure, and achieve the effect of simple structure, wide high-efficiency area, and low loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

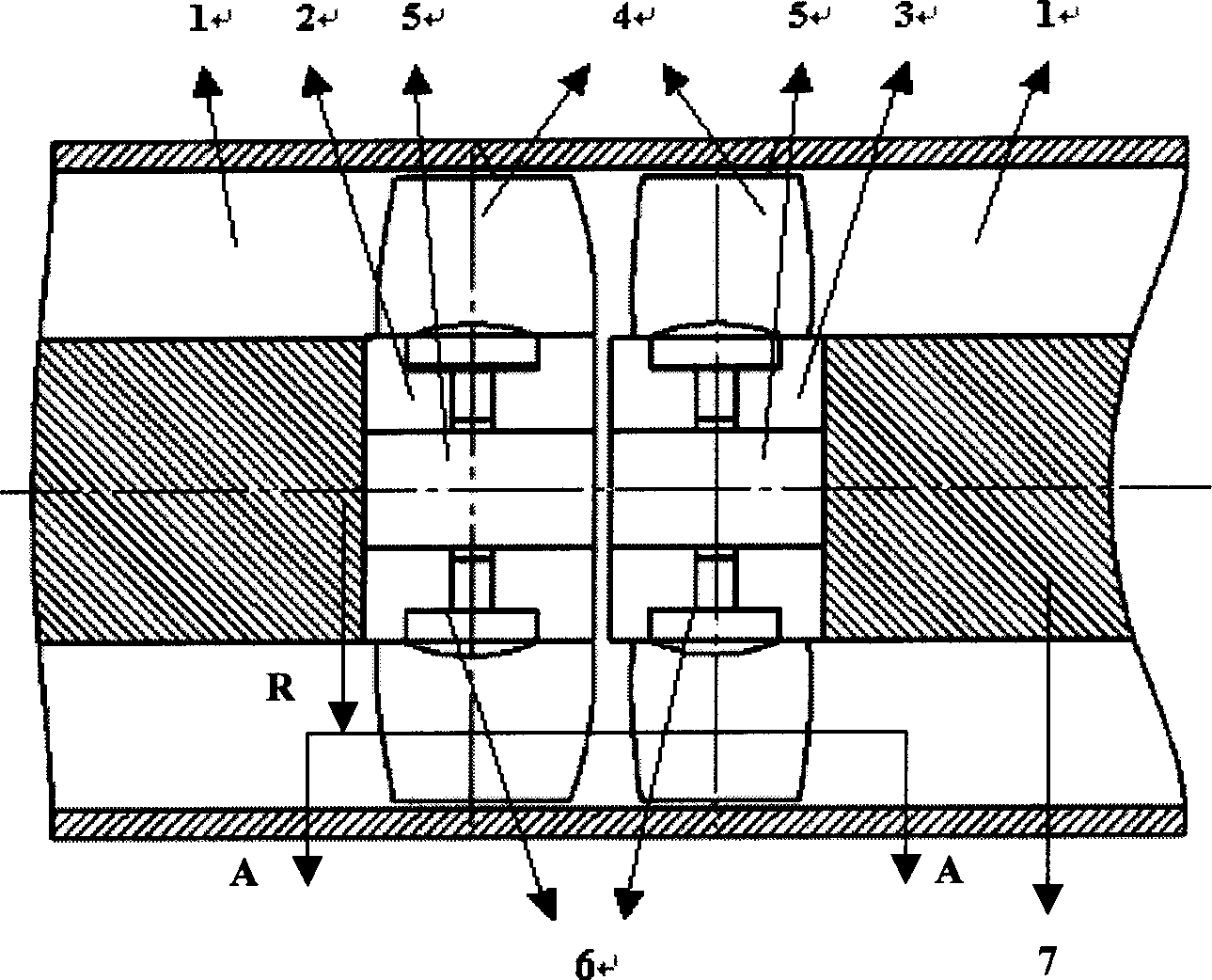

[0013] figure 1 Schematic diagram of the structure of the counter-rotating through-flow runner provided by the present invention. This counter-rotating through-flow runner includes two sets of runners using S-shaped blades 4, namely the front runner 2 and the rear runner 3, and both sets of runners use the same S-shaped blade 4 to form a Counter-rotating tubular runner. The two sets of runners are arranged in the axial direction, and the installation direction of the inlet and outlet sides of the blades of the front runner 2 is opposite to that of the blades of the rear runner 3, that is, the inlet side of the blades of the front runner is used as the rear rotor. The outlet side of the runner blade is placed, and the outlet side of the front runner blade is placed as the inlet side of the rear runner blade, such as figure 2 shown. The rotation directions of the front and rear runners are opposite, and the speed ratio is 1-2. The distance between the two sets of runners in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com