Hydraulic design method for low-specific-speed overload-free centrifugal pump impeller

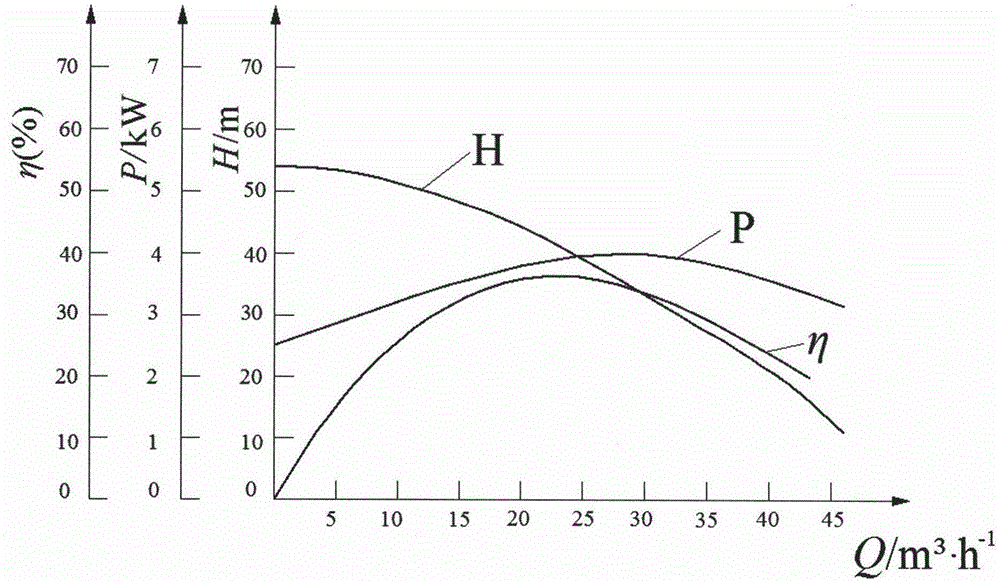

A centrifugal pump impeller and hydraulic design technology, which is applied in the direction of pumps, pump components, mechanical equipment, etc., can solve the difficulty of impeller casting process, the efficiency of the design point of the centrifugal pump with low specific speed is reduced, and the low specific speed is not given. The number of revolutions of the centrifugal pump impeller and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0226] 1. According to the given design parameters, calculate the specific speed n s , the calculation formula is

[0227] n s = 3.65 n Q H 3 / 4

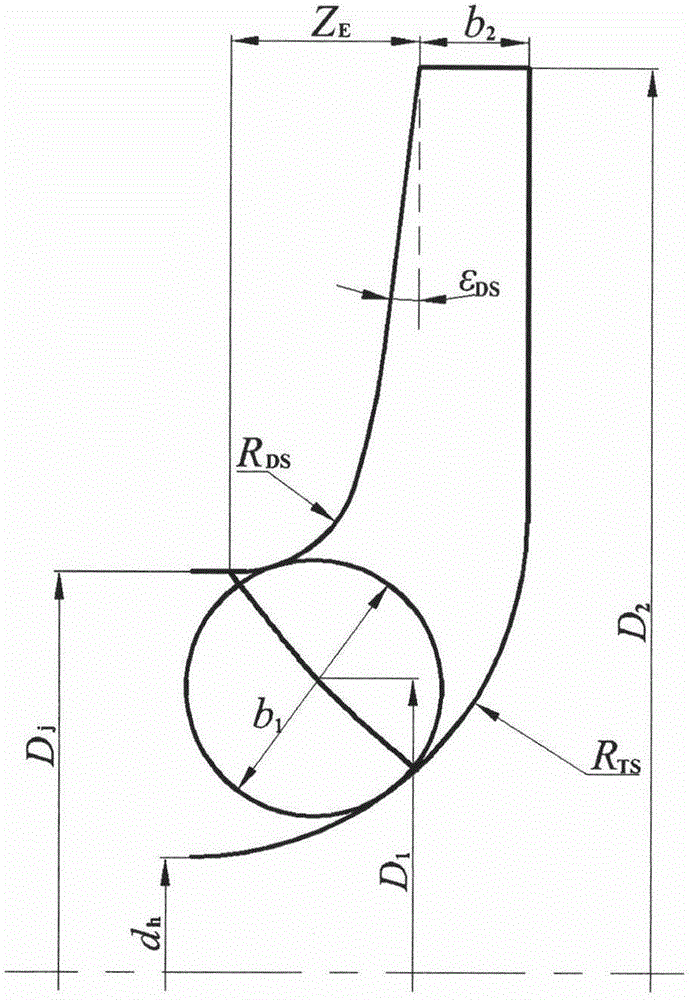

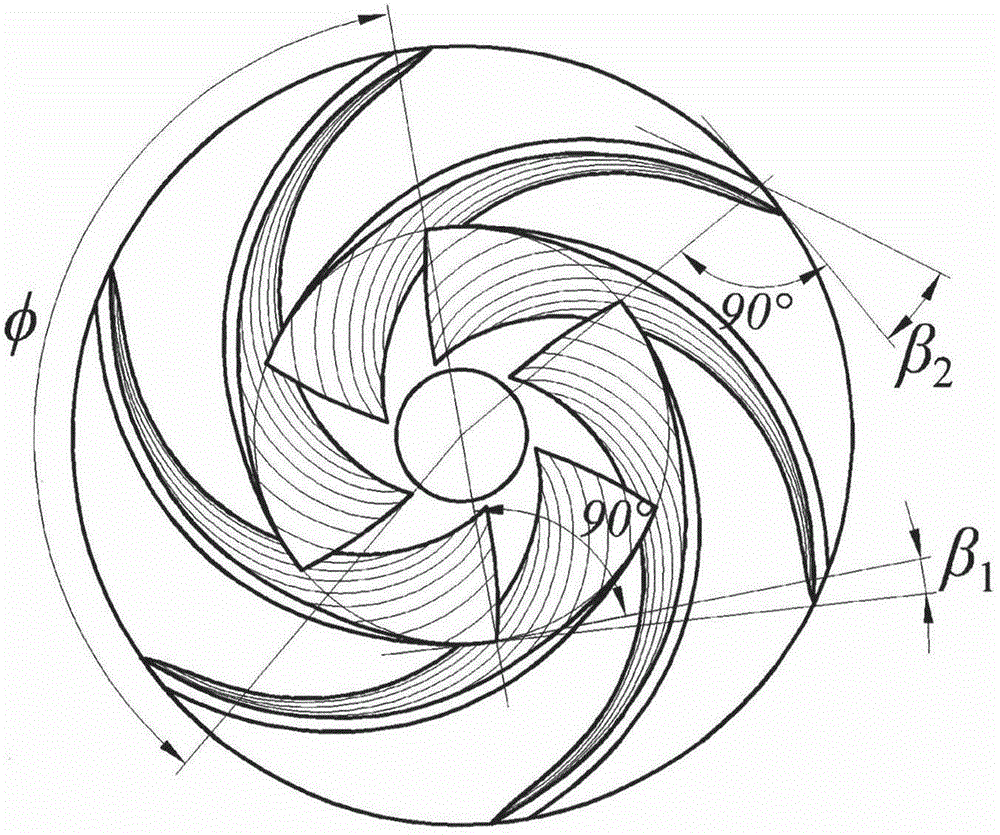

[0228] 2. Design and select the main geometric parameters of the impeller according to the following formula

[0229] D 2 = K D 2 · ( n s 100 ) - 1 2 · ( 0.01807 + 0.4651 · Q ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com