Water chilling unit combined operation optimal control method based on model prediction

A chiller and combination technology, applied in forecasting, neural learning methods, biological neural network models, etc., can solve the problems of restricting the energy-saving operation of refrigeration systems, lag in operation adjustment, and not considering energy-saving problems, and achieves good applicability and construction. Die simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings.

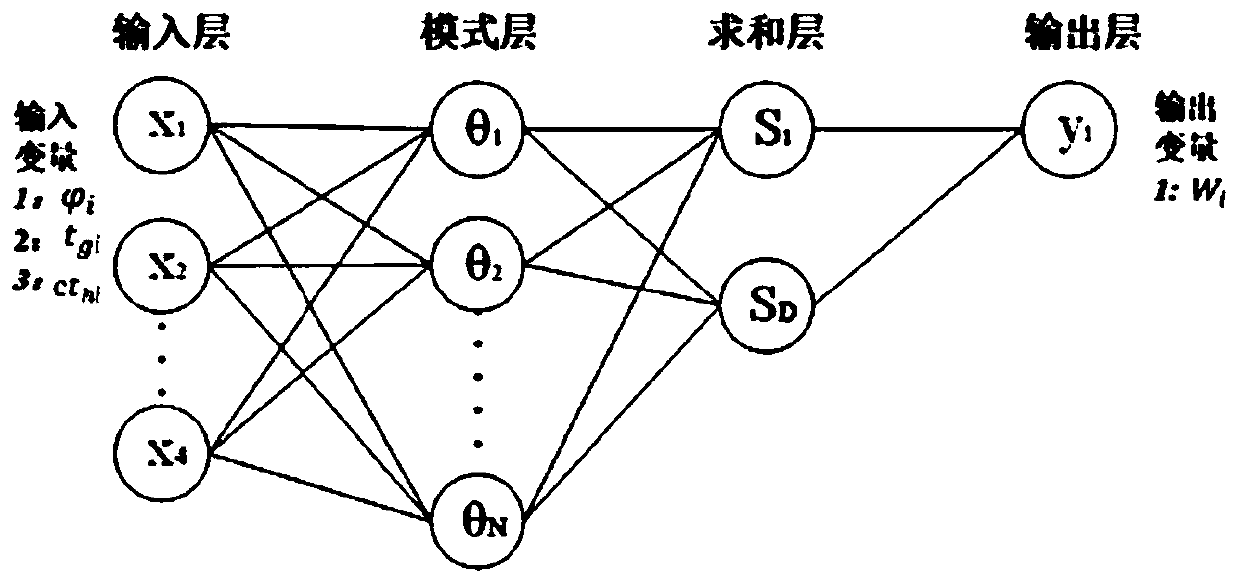

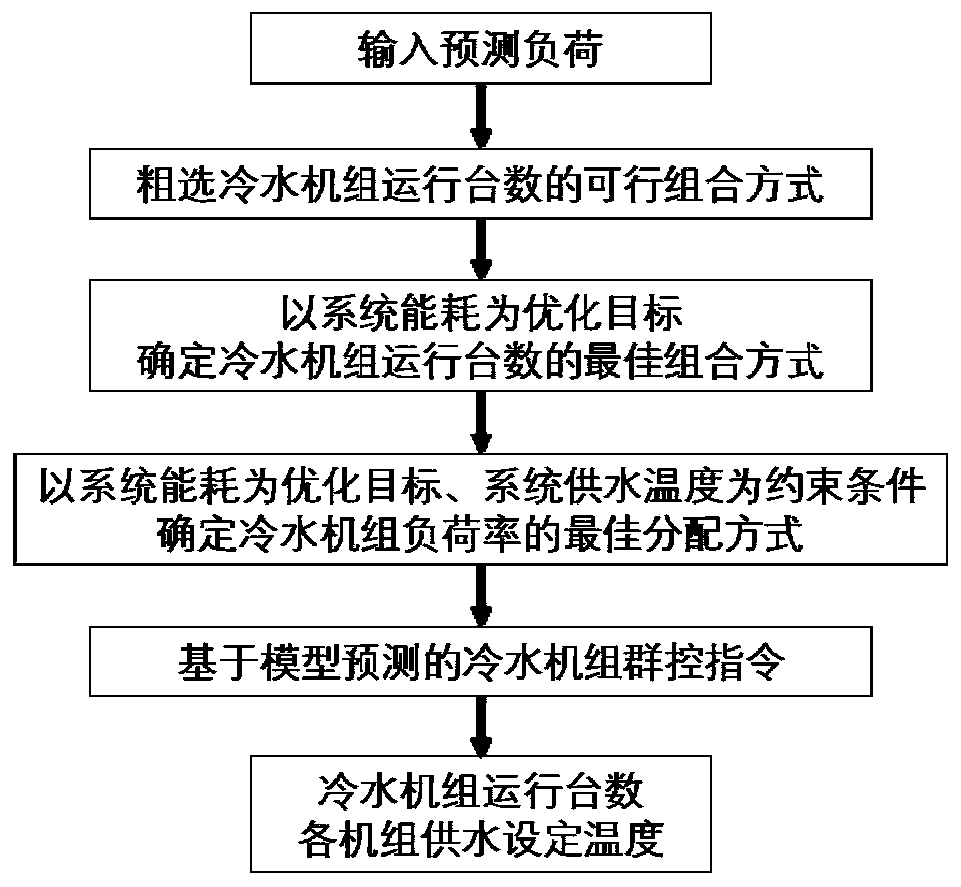

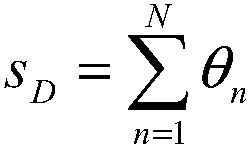

[0054] ginseng figure 1 As shown, a GRNN-based chiller energy efficiency model modeling method proposed by the present invention can be implemented in the following steps:

[0055] S1: Establish a training data set for the GRNN model.

[0056] ① Record the automatic monitoring data of the refrigeration system, the recording interval is 10 minutes, and the monitoring parameters include the operating power W of each chiller i , Chilled water supply temperature t gi , Chilled water return temperature t h , Cooling water inlet temperature ct hi .

[0057] ②According to the monitoring data and the rated cooling capacity of the unit, the load rate of the computer unit As shown in the following formula:

[0058]

[0059] Among them, C is the specific heat of water, m i , t gsi , t h It is the measured flow rate of the i-th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com