Chiller system with low capacity controller and method of operating same

a controller and low-capacity technology, applied in the field of chilling water systems, can solve the problems of low capacity demand, lower kilowatt-per-ton use, and less efficient operation of chillers, and achieve the effect of low capacity, low capacity, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

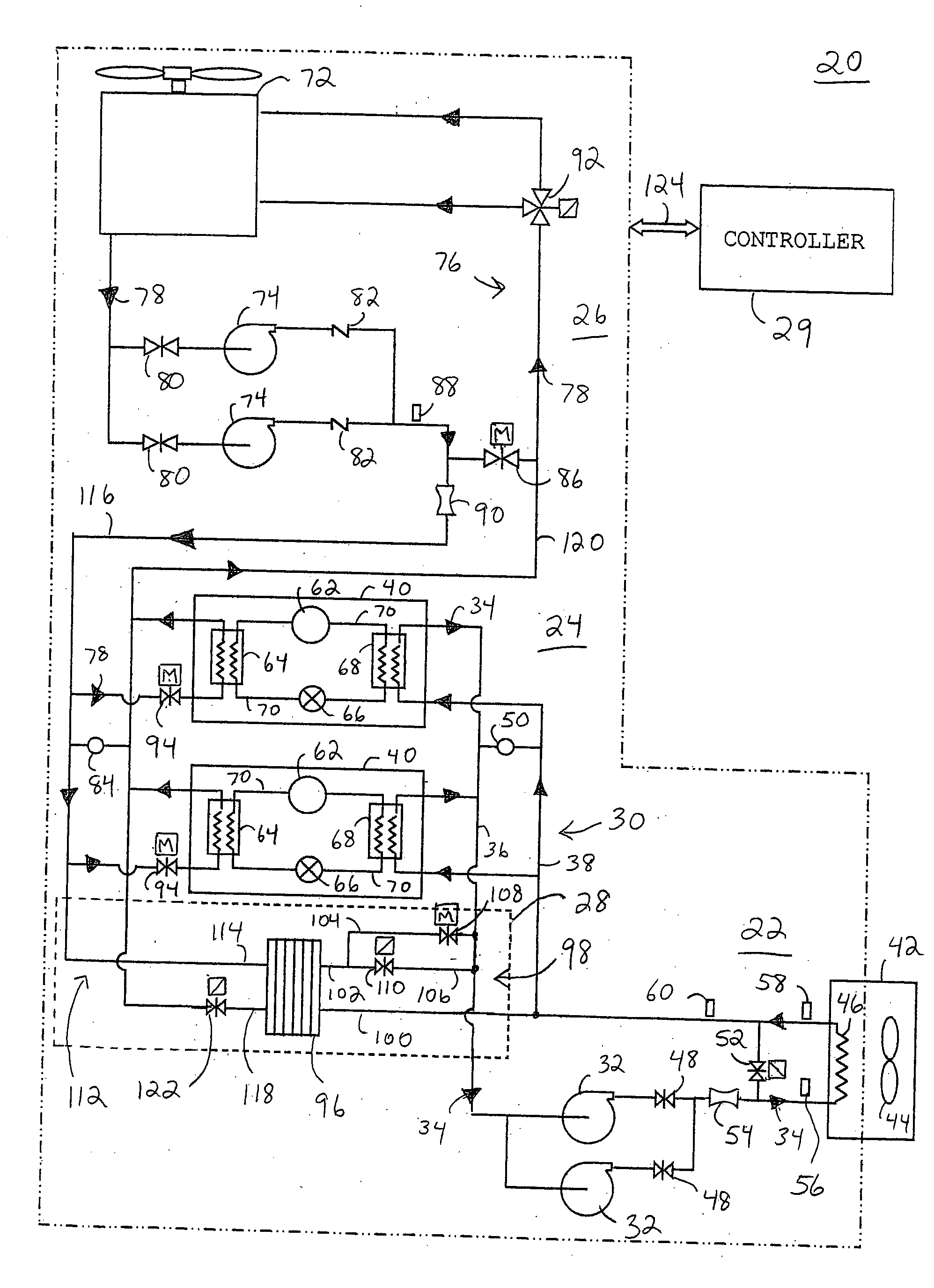

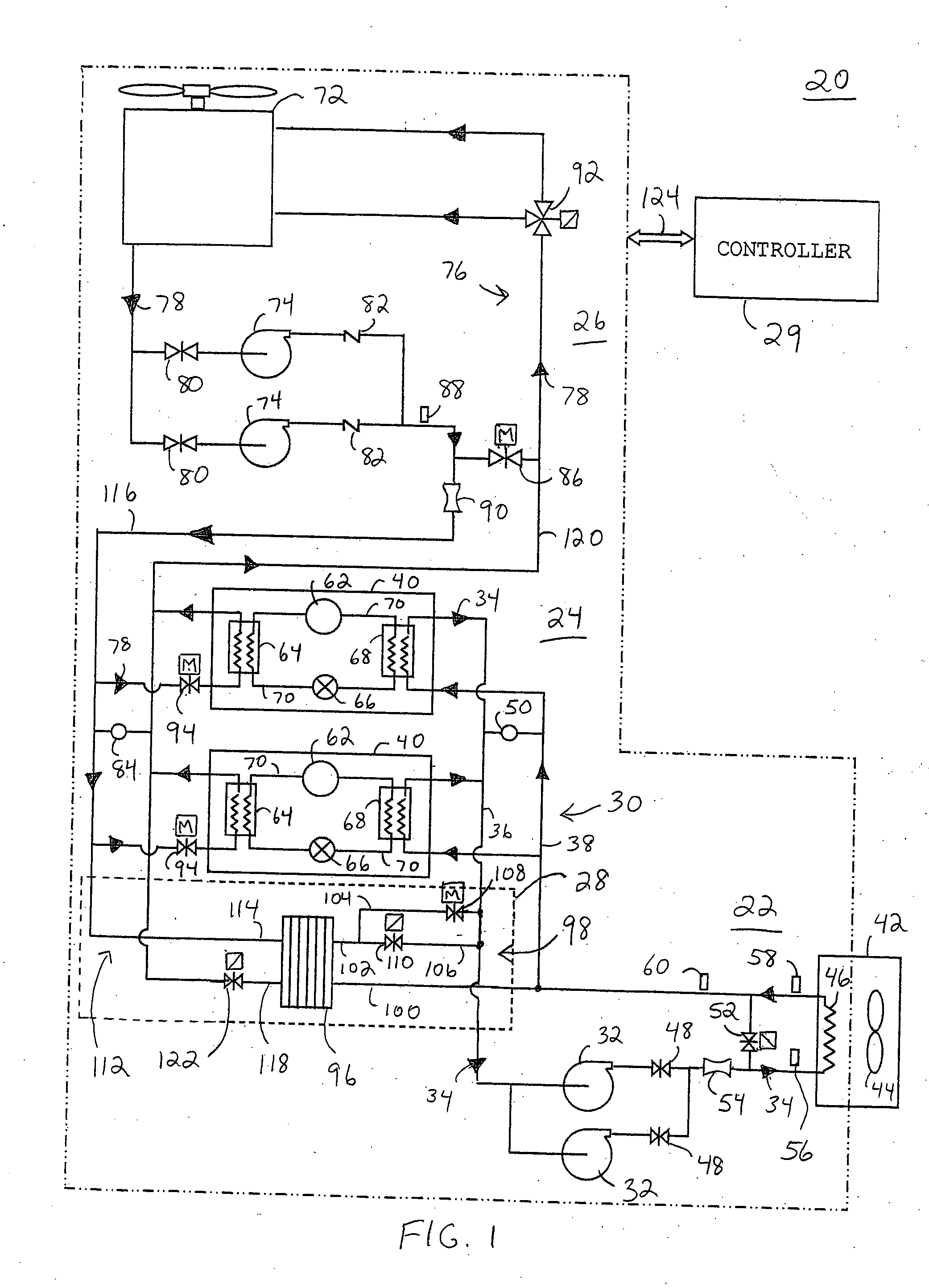

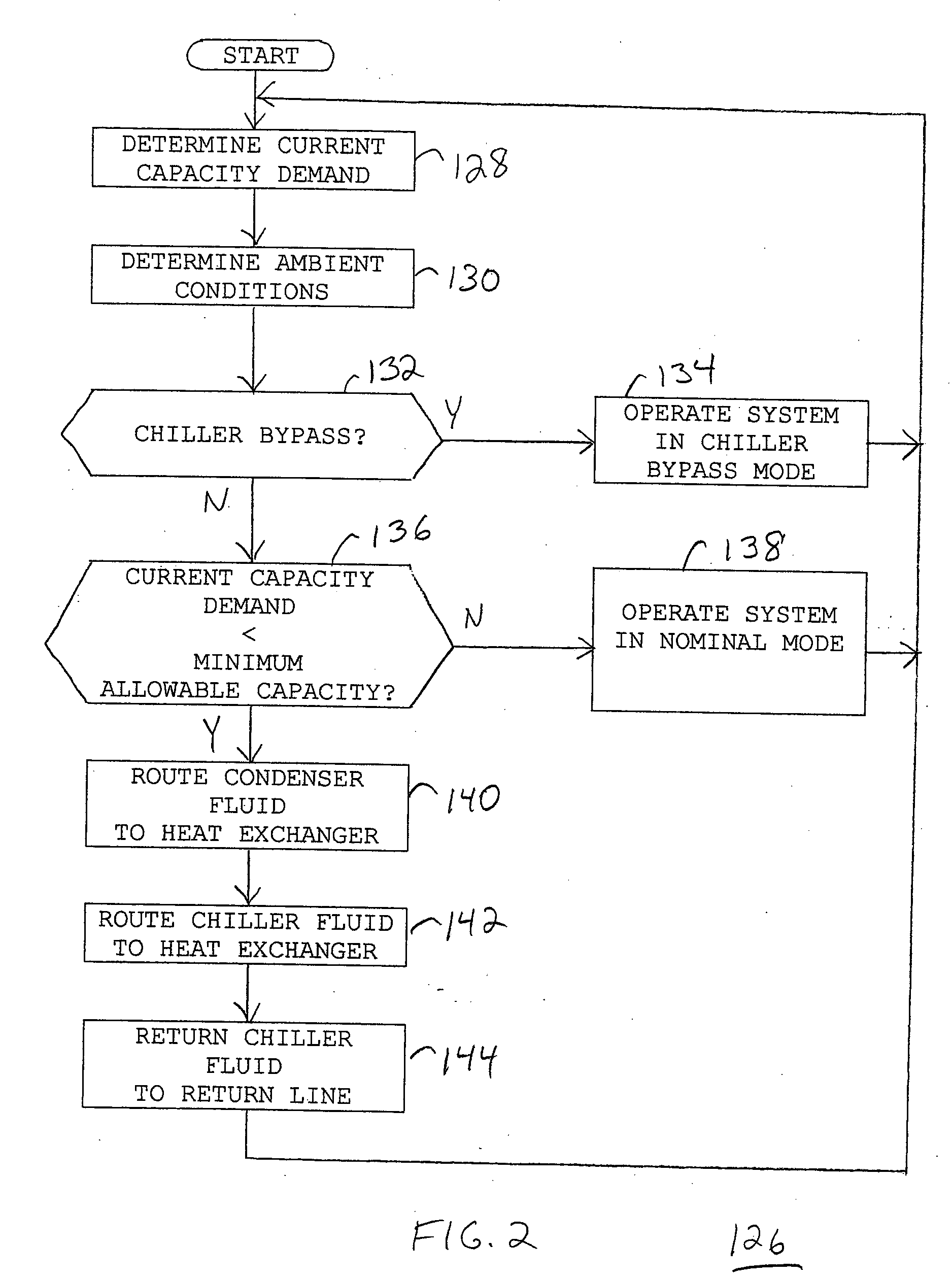

[0023]FIG. 1 shows a block diagram of a chiller system 20 in accordance with a preferred embodiment of the present invention. In general, chiller system 20 includes a chiller fluid section 22, a refrigeration section 24, a condenser fluid section 26, a low capacity controller 28, and a system controller 29.

[0024] Chiller fluid section 22 includes a chiller fluid loop 30 and pumps 32. Pumps 32 are in fluid communication with chiller fluid loop 30 for forcing a chiller fluid, represented by arrow heads 34, to circulate within chiller fluid loop 30. Chiller fluid loop 30 includes a supply line 36 and a return line 38. Supply line 36 conveys chiller fluid 34 from chillers 40 of refrigeration section 24 to an air handler 42 for conditioning the air within a space served by air handler 42. Air handler 42 uses chiller fluid 34 to transfer heat energy from the air being circulated from the space by means of a fan 44 and ductwork (not illustrated) to a heat exchange coil 46 of chiller fluid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com