Gradient laminated coating tool and preparation method thereof

A gradient coating, multi-layer coating technology, applied in coating, chemical instruments and methods, metal material coating technology, etc. Apply negative effects and other issues to achieve the effect of increasing bonding strength, good overall performance, and improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

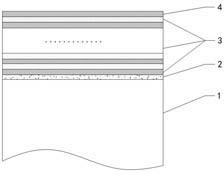

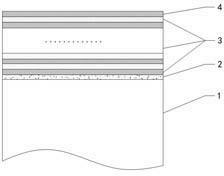

Image

Examples

Embodiment 1

[0039] In this embodiment, the cutting tool is a common milling insert, its base material is: cemented carbide YT15, and the coating material is: Ti, ZrN and ZrTiN.

[0040] The preparation method is: arc ion plating deposits a Ti transition layer of about 30-40nm, and then alternately deposits ZrTiN and ZrN hard coatings with a thickness of about 150-200nm by a nitrogen flow gradient method, and finally the surface is a ZrTiN coating (deposition When using 1 Ti and 1 Zr arc target).

[0041] Specifically include the following steps:

[0042] 1) Pre-treatment: Polish the surface of the milling blade whose substrate is cemented carbide YT15 to remove surface oil, rust and other impurities, then put it in alcohol and acetone in turn, and ultrasonically clean it for 30 minutes each to remove oil and other impurities on the surface of the tool Attachments, after the hair dryer is fully dried, quickly put them into the coating machine, and vacuumize to 5.0×10 -3 Pa, heat to 300 ℃,...

Embodiment 2

[0054] In this embodiment, the tool is an ordinary twist drill, and its base material is: high-speed steel W18Cr4V; the coating material is: Ti, ZrN and ZrTiN.

[0055] The preparation method is: arc ion plating deposits a Ti transition layer of about 30-40nm, and then alternately deposits ZrTiN and ZrN hard coatings with a thickness of about 150-200nm by a nitrogen flow gradient method, and finally the surface is a ZrTiN coating (deposition When using 1 Ti and 1 Zr arc target).

[0056] Specifically include the following steps:

[0057] 1) Pre-treatment: Grind the surface of the twist drill substrate whose substrate material is high-speed steel W18Cr4V with No. 2000 sandpaper to remove impurities such as oil stains and rust on the surface, then put them in alcohol and acetone in turn, and ultrasonically clean them for 30 minutes each to remove the tool surface Oil stains and other attachments should be quickly put into the coating machine after the hair dryer is fully dried,...

Embodiment 3

[0068] The tool is an ordinary milling insert, the base material is: cemented carbide YT15; the coating material is: Ti, Ti / Zr and MoS 2 / Ti / Zr;

[0069] Deposition using 1 Ti arc target, 1 Zr arc target and 2 MoS 2 Intermediate frequency sputtering target, its preparation process is:

[0070] 1) Pre-treatment: Polish the surface of the cemented carbide YT15 milling blade substrate to remove surface oil, rust and other impurities, then put them in alcohol and acetone in sequence, and ultrasonically clean them for 25 minutes each to remove oil and other attachments on the surface of the tool. After the hair dryer is fully dried, quickly put it into the coating machine, and vacuumize to 5.0×10 -3 Pa, heat to 300 ℃, keep warm for 30~40 min;

[0071] 2) Ion cleaning: pass Ar gas, the pressure is 1.5 Pa, turn on the bias power supply, voltage 1000 V, duty cycle 0.2, glow discharge cleaning for 15 min; reduce the bias voltage to 800 V / 0.2, turn on the ion source ion cleaning 25...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com