Ultra-thick high-strength high low-temperature toughness steel plates for ocean platforms and production method thereof

An offshore platform, low temperature toughness technology, applied in the field of low alloy quenched and tempered steel manufacturing, can solve the problems of low temperature impact toughness can not meet, can not use pile leg material, does not meet relevant standards, specification requirements, etc., to achieve excellent welding performance, good welding performance The effect of cutability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

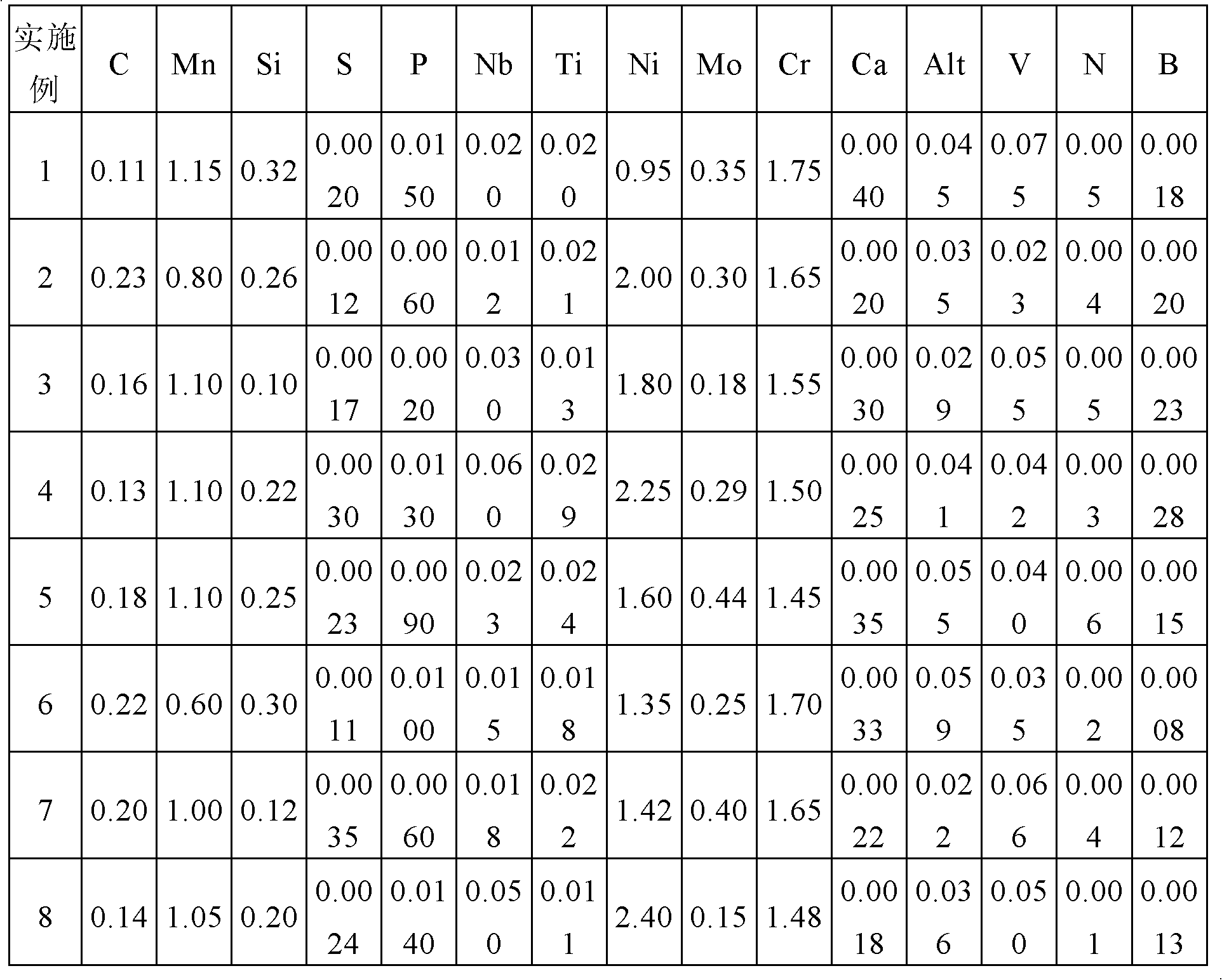

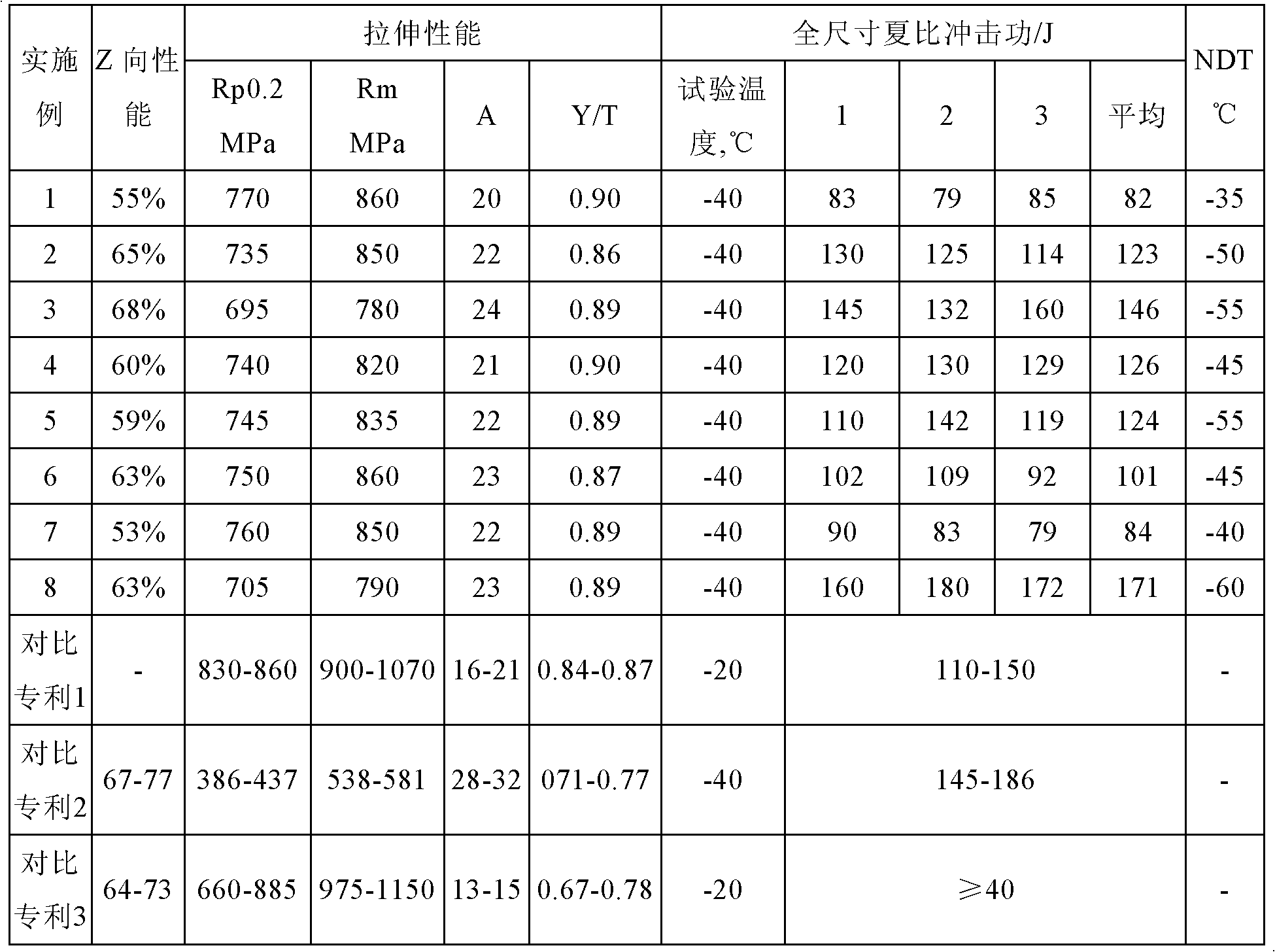

Examples

Embodiment 1、7

[0054] It is used to manufacture thick steel plates with a thickness specification of 40.0mm.

[0055] 1. Smelting, casting, RH and LF smelting;

[0056] 2. Blooming, heating temperature for blooming: 1270℃; temperature for blooming and rolling: 980℃; temperature for slow cooling out of the first rolling pit: 300℃; stress relief annealing temperature: 500℃; Stress relief annealing holding time: 11 hours;

[0057] 3. Rolling, thick plate rolling heating temperature: 1090°C; thick plate rolling finish rolling temperature: 930°C; thick plate rolling pit slow cooling temperature 150°C;

[0058] 4. Heat treatment, quenching heating temperature: 975°C; tempering heating temperature: 660°C.

Embodiment 2、3

[0060] 1. It is used to manufacture thick steel plates with a thickness specification of 200.0mm.

[0061] 2. Smelting, casting, RH and LF smelting;

[0062] 3. Blooming, heating temperature for blooming: 1290°C; temperature for blooming and rolling: 930°C; temperature for slow cooling out of the first rolling pit: 350°C; stress relief annealing temperature: 550°C;

[0063] 4. Rolling, thick plate rolling heating temperature: 1100°C; thick plate rolling finish rolling temperature: 940°C; thick plate rolling pit slow cooling pit temperature 200°C;

[0064] 5. Heat treatment, quenching heating temperature: 935°C; tempering heating temperature: 650°C.

Embodiment 4、8

[0066] It is used to manufacture thick steel plates with a thickness specification of 127.0mm.

[0067] 1. Smelting, casting, RH and LF smelting;

[0068] 2. Blooming, heating temperature for blooming: 1280°C; temperature for blooming and rolling: 1030°C; temperature for slow cooling out of the first rolling pit: 250°C; stress relief annealing temperature: 580°C;

[0069] 3. Rolling, thick plate rolling heating temperature: 1170°C; thick plate rolling finish rolling temperature: 920°C; thick plate rolling pit slow cooling pit temperature 100°C.

[0070] 4. Heat treatment, quenching heating temperature: 975°C; tempering heating temperature: 620°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com