Diirect-driven generating set

A technology for generator sets and generators, applied in the direction of electric components, electrical components, electromechanical devices, etc., can solve the problems of high noise and torque fluctuation of direct-drive switched reluctance generators, improve market competitiveness and reduce tilt. The effect of turning torque and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

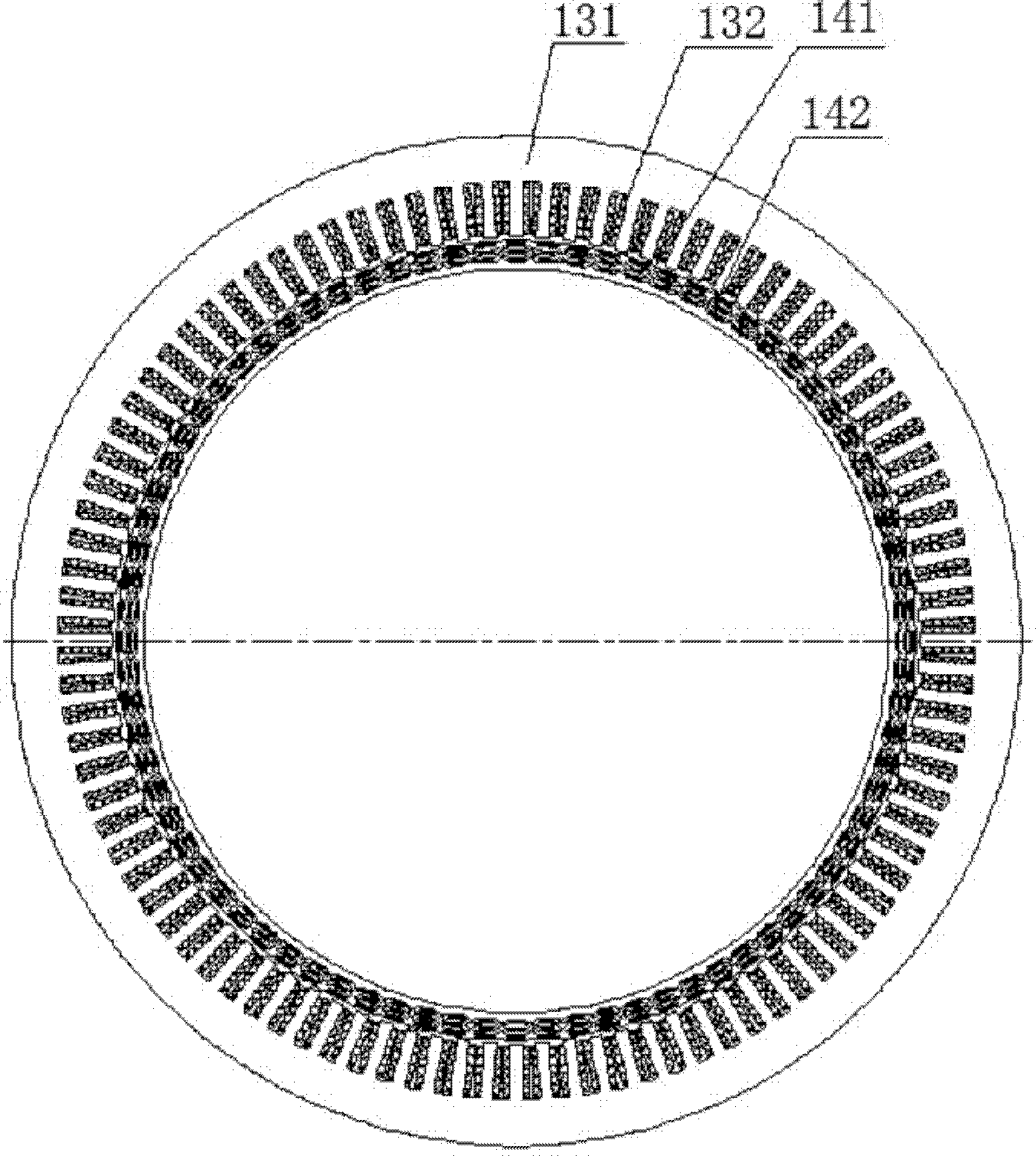

[0033] Such as figure 1 As shown, it is a sectional view of the stator and rotor of the direct drive generator in the specific embodiment of the present invention, including the stator and the rotor. The stator includes a stator core 131 and a stator winding 132, and the rotor includes a rotor core 141 and rotor permanent magnets 142 arranged in multiple air slots of the rotor core. The stator winding 132 may adopt a distributed winding form, a fractional slot winding form, a fractional slot single-pitch winding form, and the like.

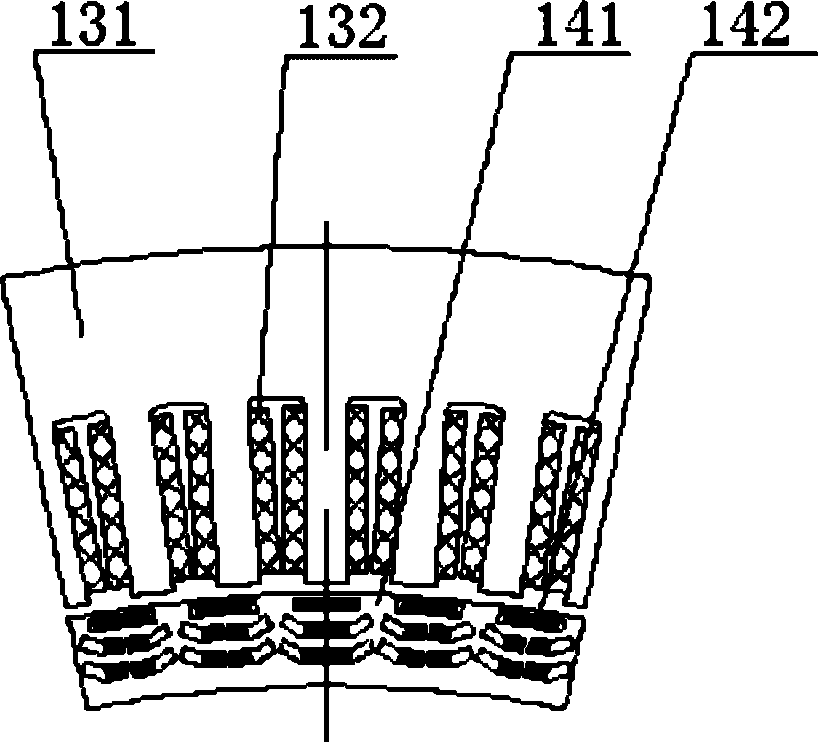

[0034] Such as figure 2 As shown, it is an enlarged view of the 1 / 16 model of the stator and rotor section of the direct drive generator in the specific embodiment of the present invention.

[0035] The working principle of synchronous permanent magnet reluctance ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com