rotary jet internal combustion engine

A technology of rotary jet and internal combustion engine, applied in the field of internal combustion engine and rotary jet internal combustion engine, can solve the problems of low thermal efficiency of internal combustion engine and narrow working speed range, and achieve the effects of high compression ratio, wide working speed range and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to the drawings and embodiments, but it is not intended to limit the present invention.

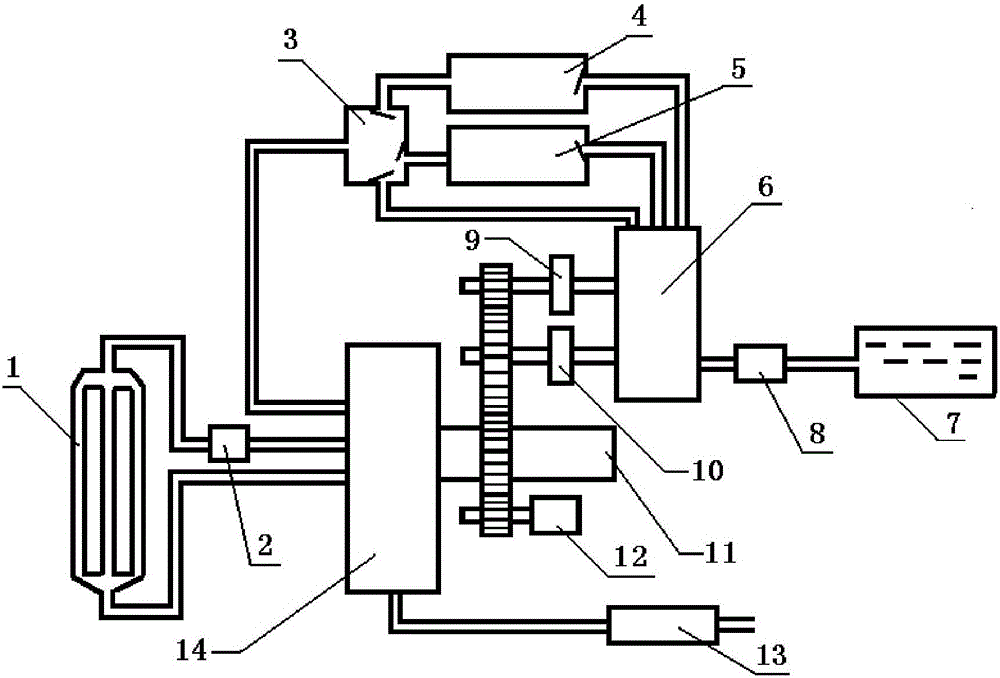

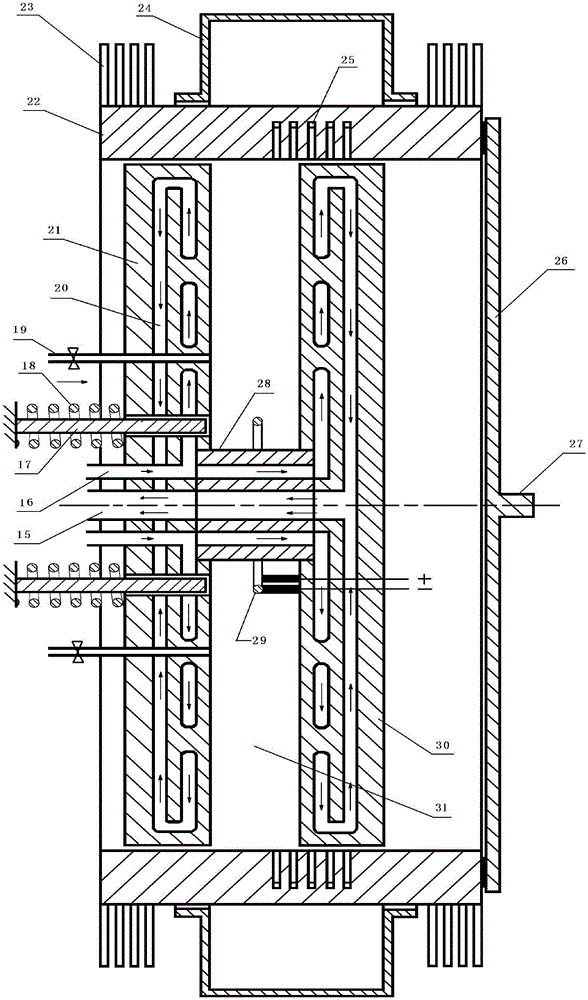

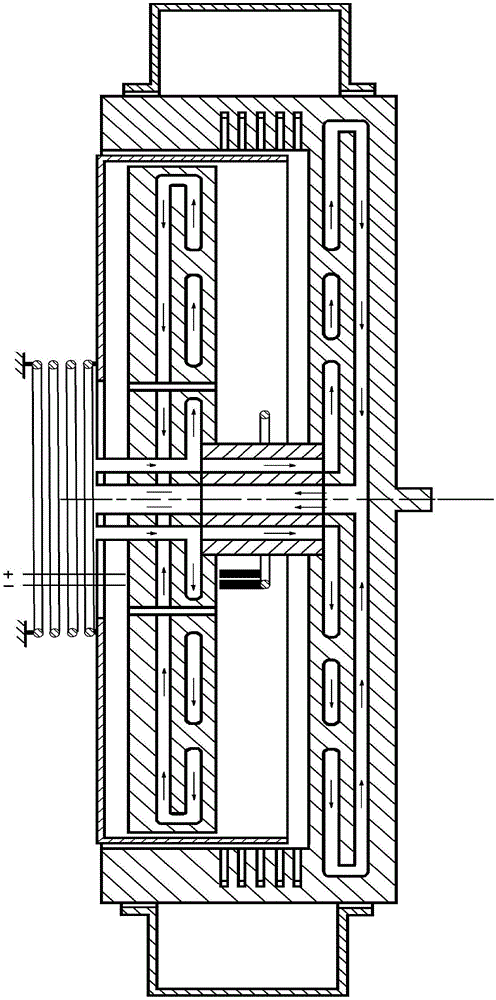

[0023] in figure 1 , 2 In the structure shown in the present invention, a rotary jet internal combustion engine designed by the present invention includes an electronic control unit (ECU), a rotary jet combustion chamber assembly 14, an air compression system, an emergency starter motor, an air storage device, a cooling system, and fuel Supply system, lubrication system, power generation storage equipment, exhaust gas processing device; electronic control unit (ECU) is similar in structure and function to the electronic control unit of ordinary internal combustion engines. It is the control center of the entire internal combustion engine. It uses sensors to collect accelerator, brake, temperature, pressure, Speed and other parameters are analyzed and calculated, and then various switches, valves and other components...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com