A cantilever mounted device capable of measuring torque at high speed

A cantilever installation, high-speed technology, applied in measuring devices, measuring torque/torsion force during tightening, engine testing, etc., to achieve a wide range of operating speed, wide application range, and simple and clear design ideas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

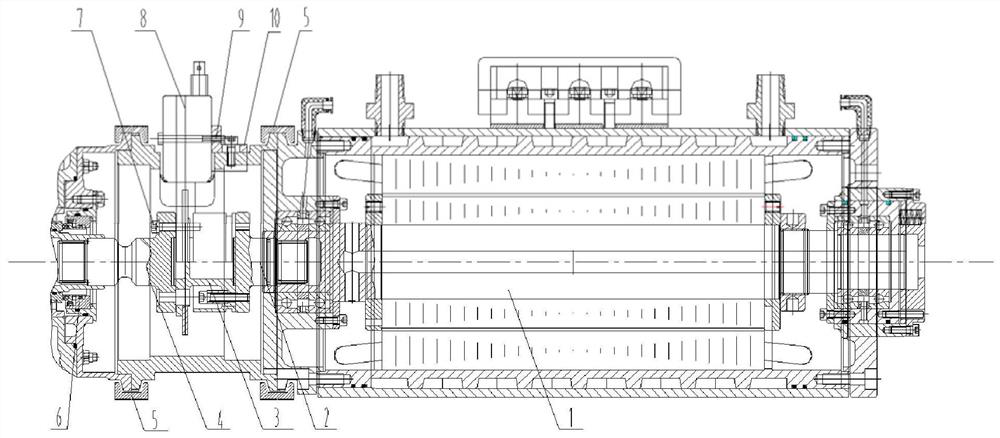

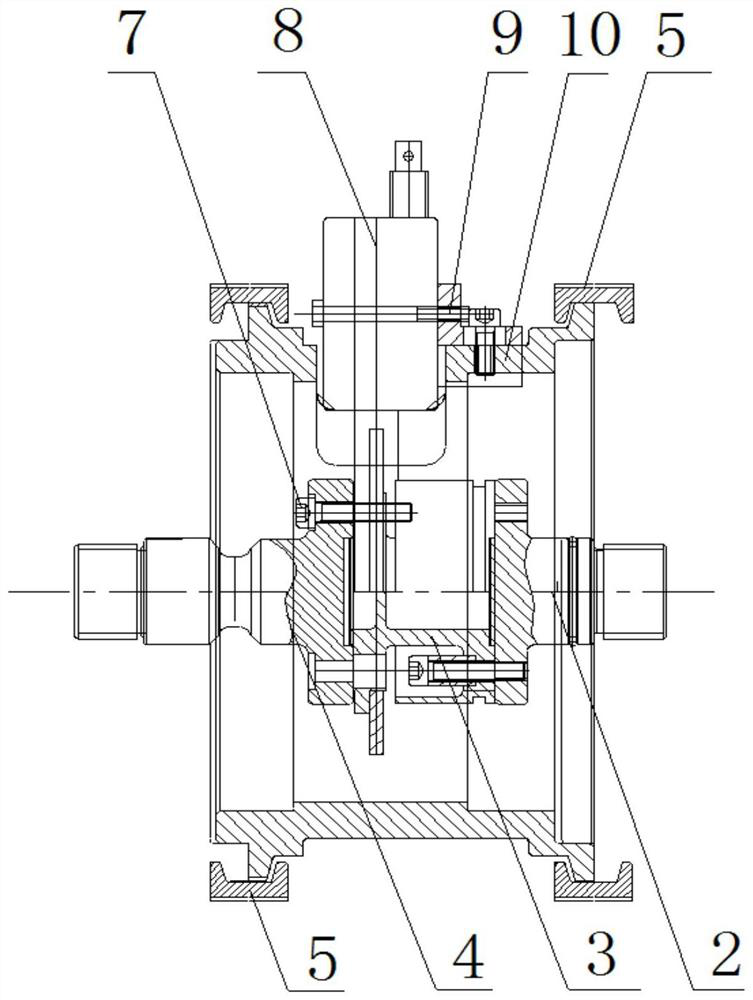

[0033] (1) According to the structure and characteristics of the torque sensor, design the adapter shaft suitable for the installation side of the rotor flange of the torque sensor. The spline shaft Ⅰ4 is the transmission chain formed by the connection between the rotor 3 of the torque sensor and the motor mounting seat 6 of the aircraft accessory casing. On the casing and the AC motor 1, no bearings are used to support the two motor spline shafts, and the design span of the overlapping structure (including the rotor 3 of the torque sensor) is 183 mm.

[0034] (2) According to the structure type of the power source and the test piece, the interface type of the adapter shaft is selected, and the connection structure of the motor spline shaft II2 and the motor spline shaft I4 is designed as an external spline structure, and the design of the splines at both ends It needs to meet the spline technical requirements of the aircraft accessory case and alternator 1, and the drive shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com