Position-free control method of current source type synchronous reluctance motor system

A synchronous reluctance motor, current source technology, applied in the direction of motor generator control, electronically commutated motor control, motor control, etc., can solve the problems such as the application of few current source motor drive systems, and avoid system reliability The effects of lowering, strong suppression, and increased sensitivity to disturbance and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

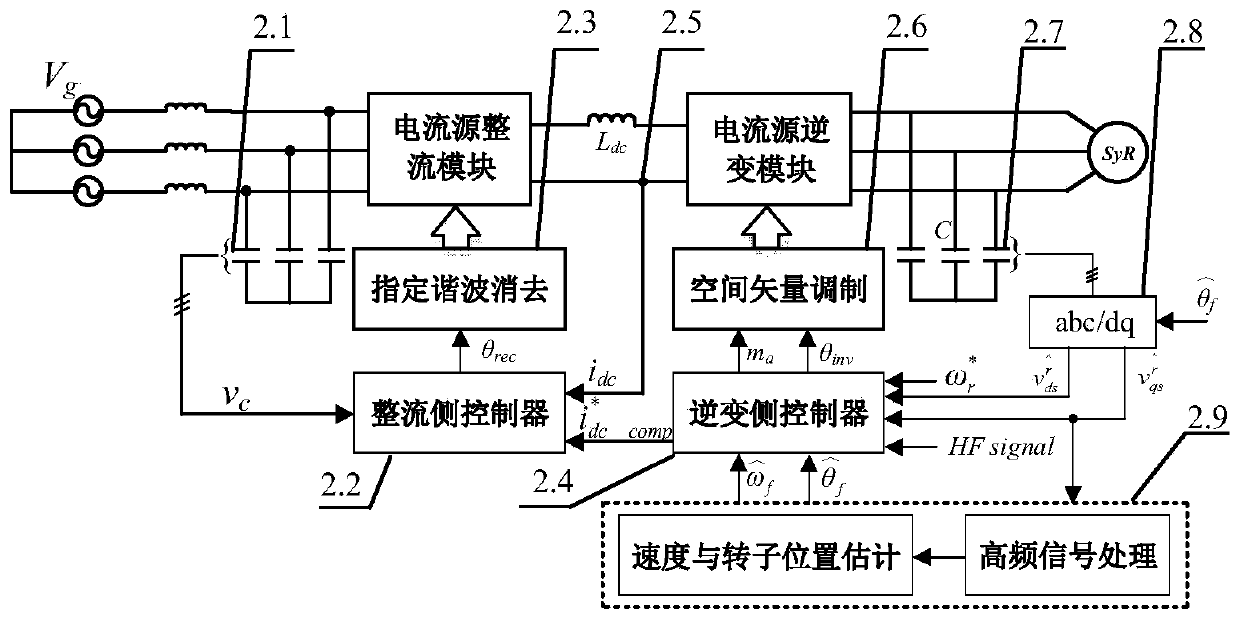

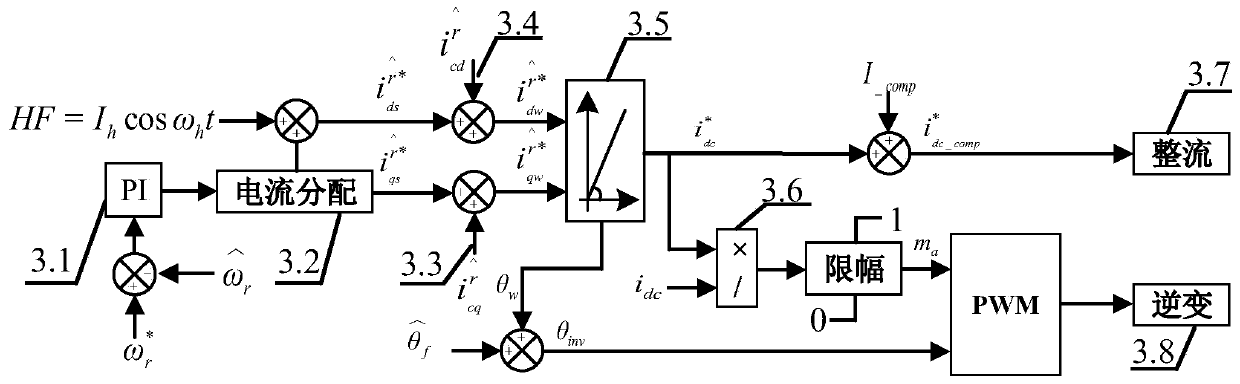

[0029] Below in conjunction with accompanying drawing, technical scheme of the present invention is described in further detail:

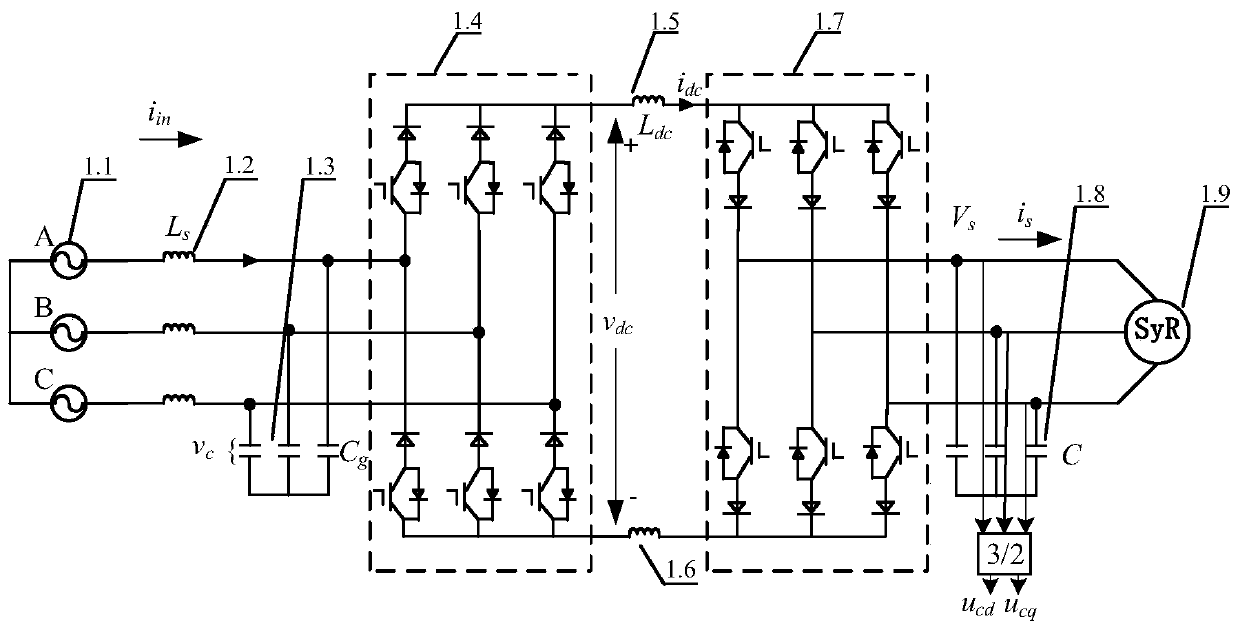

[0030] Such as figure 1 The topology of the current source synchronous reluctance motor drive system shown, including:

[0031] A synchronous reluctance motor 1.9, which is connected in parallel with a three-phase filter capacitor bank 1.8;

[0032] The three-phase filter capacitor bank 1.8 is connected to the current source inverter unit 1.7;

[0033] The current source inverter unit 1.7 is connected in series with the DC bus inductors 1.5 and 1.6 through the incoming terminal of the DC side;

[0034] The DC bus inductance 1.5, 1.6 is fed by the current source rectifier unit 1.4;

[0035] The current source rectifier unit 1.4 is connected to the LC filter at the grid side;

[0036] The LC filter includes a three-phase grid-connected inductor 1.2 and a three-phase filter capacitor 1.3 connected in parallel therewith, wherein: the other end of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com