A Fractional Slot Concentrated Winding Pole-changing Memory Motor Without Changing the Winding Arrangement

A technology of concentrated winding and memory motor, which is applied to the shape/style/structure of winding conductors, asynchronous induction motors, electric components, etc., can solve the problems of reduced electromagnetic performance, less than ideal structural design, complex motor control, etc., to reduce the amount of consumption. , The effect of facilitating industrial mass production and simplifying the winding connection method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

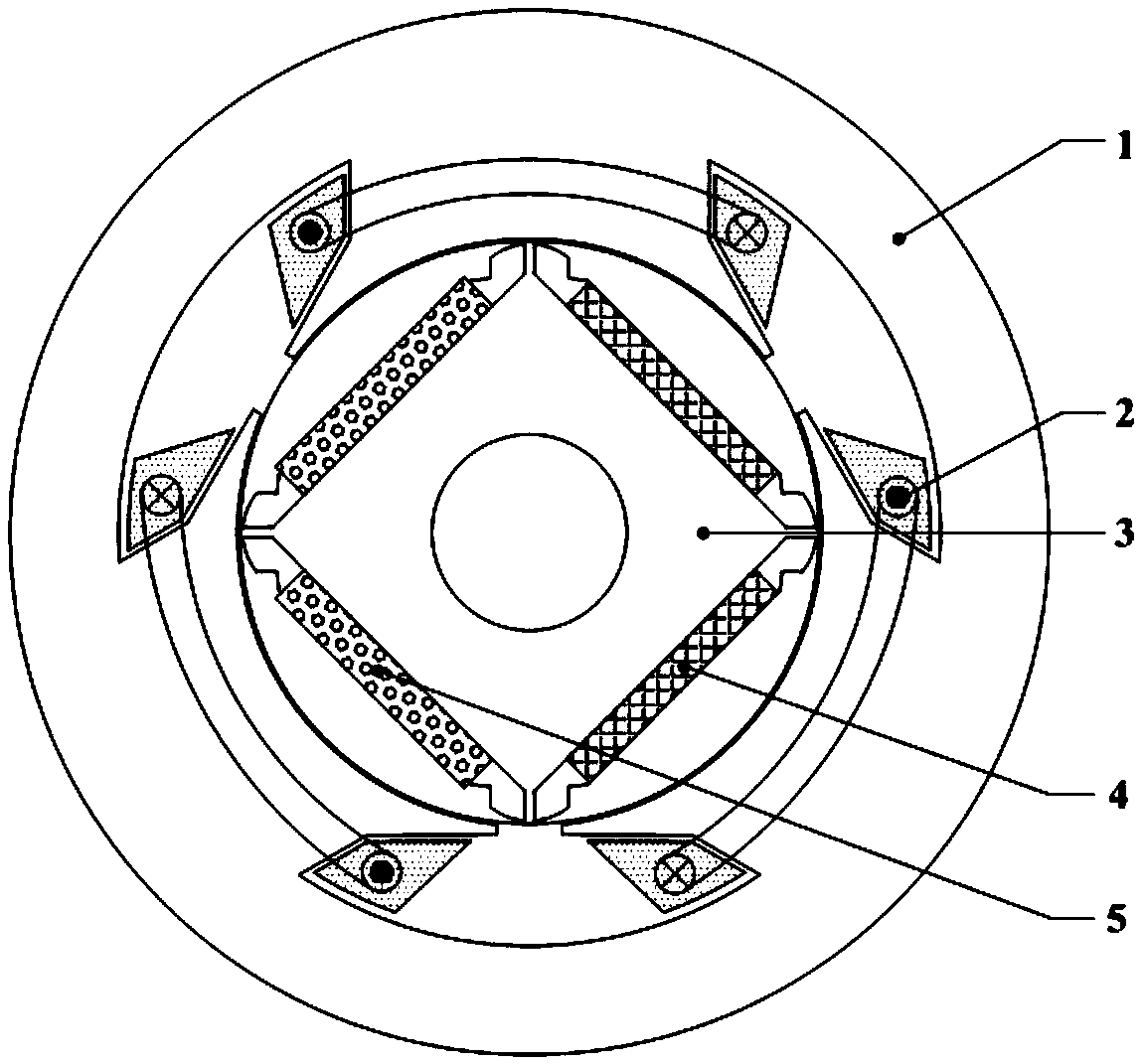

[0047] Such as Figure 1a As shown, the three-phase fractional slot concentrated winding 2:1 (4 / 2 pole) pole-changing memory motor, the stator core 1 contains three stator teeth, and the A, B and C three-phase armature windings 2 are wound in turn, the armature winding The fractional slot concentrated winding is adopted, and the armature slot for placing the fractional slot concentrated winding is arranged between two adjacent stator teeth; the rotor is coaxial with the stator, surrounded by three stator teeth of the stator core, and the rotor has two built-in high corrections A coercive force NdFeB permanent magnet 4 and two low coercive force AlNiCo permanent magnets 5; the low coercive force AlNiCo permanent magnet is thicker than the high coercive force NdFeB permanent magnet (NdFeB) The thickness of the permanent magnet, the four permanent magnets are evenly distributed along the radial direction of the rotor, and each permanent magnet is installed in a "one" shape to form...

specific Embodiment approach 2

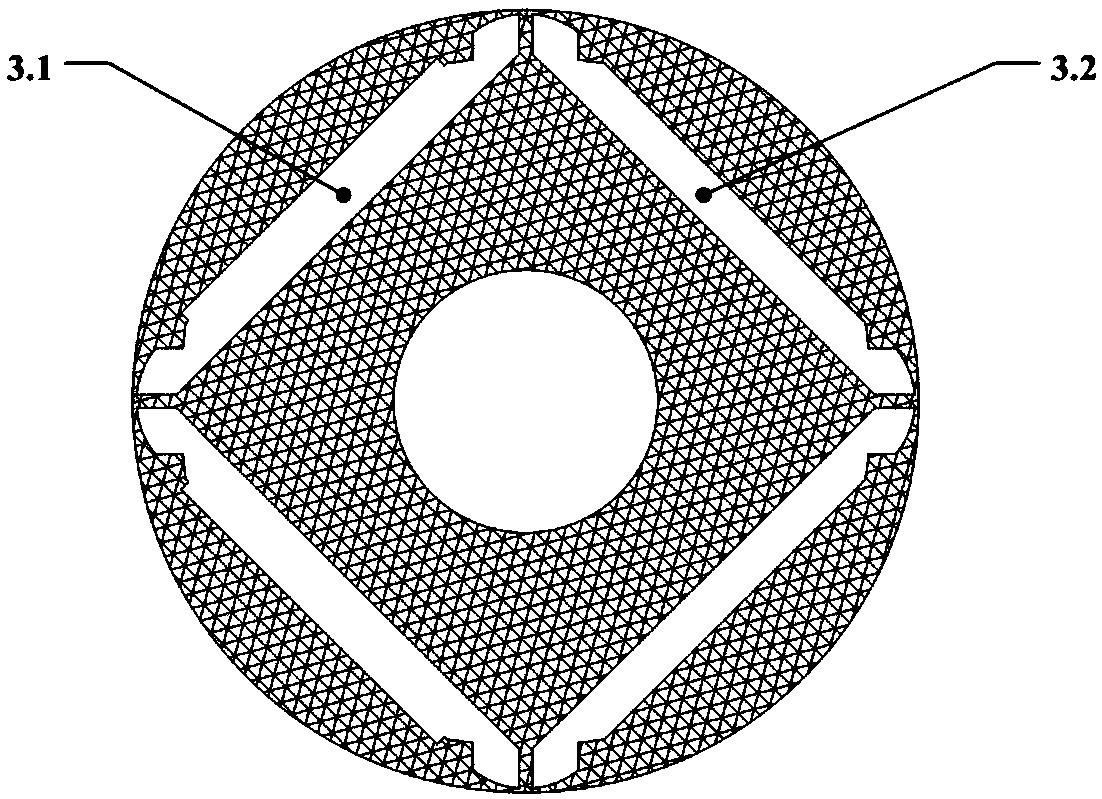

[0051] Such as figure 2 As shown, it is a five-phase fractional slot concentrated winding 2:1 (8 / 4 pole) pole-changing memory motor. The stator core 1 contains ten stator teeth, and the five-phase armature windings of A, B, C, D and E are wound sequentially. 2. The armature winding adopts fractional slot concentrated winding, and an armature slot for placing fractional slot concentrated winding is arranged between two adjacent stator teeth; the rotor is coaxial with the stator and is surrounded by ten stator teeth of the stator core. The rotor has four high-coercivity neodymium-iron-boron (NdFeB) permanent magnets 4 and four low-coercivity AlNiCo permanent magnets 5, and the thickness of the low-coercivity AlNiCo permanent magnets is greater than that of high The thickness of the coercivity neodymium iron boron (NdFeB) permanent magnet, eight permanent magnets are evenly distributed along the radial direction of the rotor, and each permanent magnet is installed in a "one" sha...

specific Embodiment approach 3

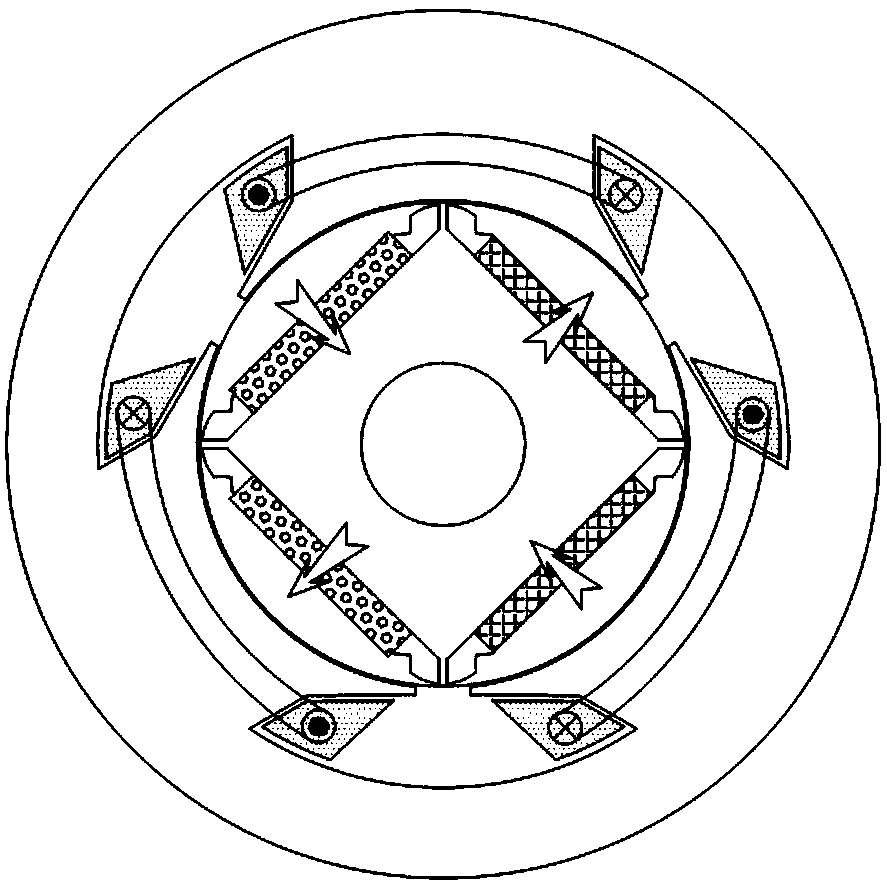

[0054] Such as image 3 As shown, it is a three-phase fractional slot concentrated winding 2:1 (12 / 6 pole) pole-changing memory motor. The stator core 1 contains nine stator teeth, and the A, B and C three-phase armature windings 2 are wound in sequence. The pivot winding adopts the fractional slot concentrated winding, and the armature slot for placing the fractional slot concentrated winding is arranged between two adjacent stator teeth; the rotor is coaxial with the stator, surrounded by nine stator teeth of the stator core, and the rotor has six built-in High-coercivity neodymium-iron-boron (NdFeB) permanent magnets 4 and six low-coercivity AlNiCo (AlNiCo) permanent magnets 5, the thickness of the low-coercivity AlNiCo (AlNiCo) permanent magnets is thicker than that of high-coercivity NdFeB The thickness of iron boron (NdFeB) permanent magnets, twelve permanent magnets are evenly distributed along the radial direction of the rotor, and each permanent magnet is installed in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com