Rotary piston machine

A technology of rotating pistons and pistons, which is applied to rotating or oscillating piston engines, oscillating piston machines, and internal combustion piston engines. Large environmental protection use, large flow, and large working speed range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

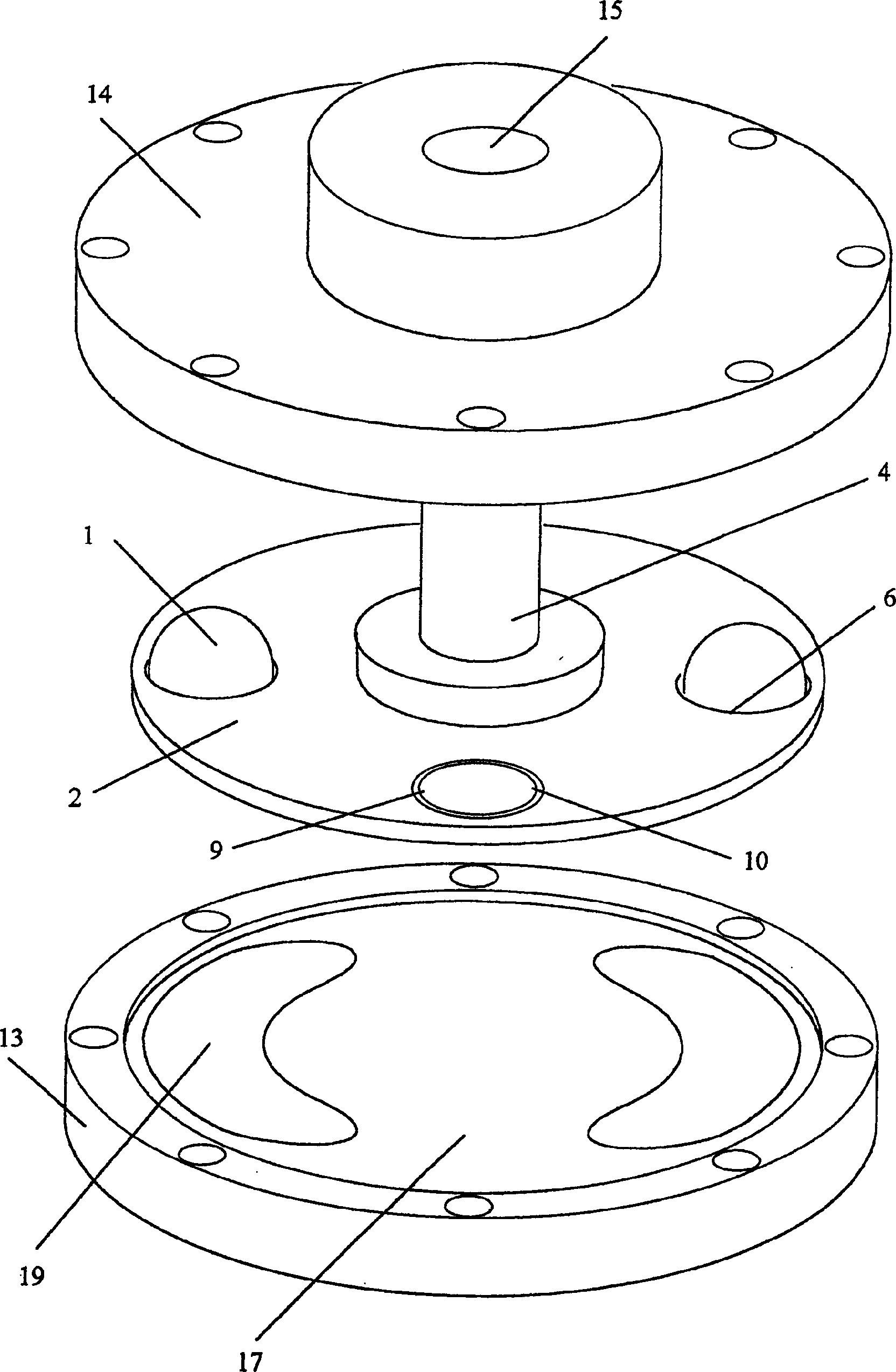

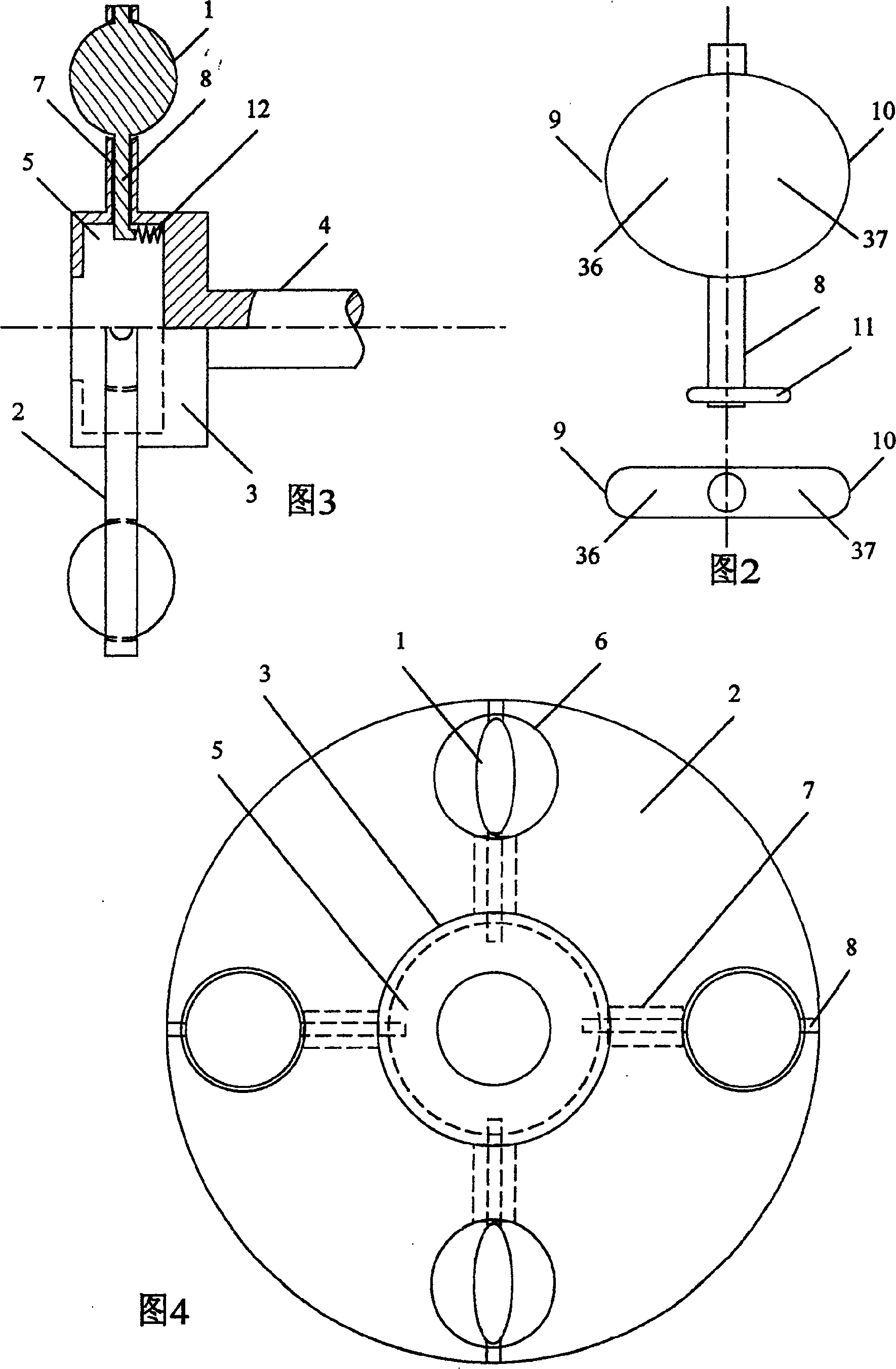

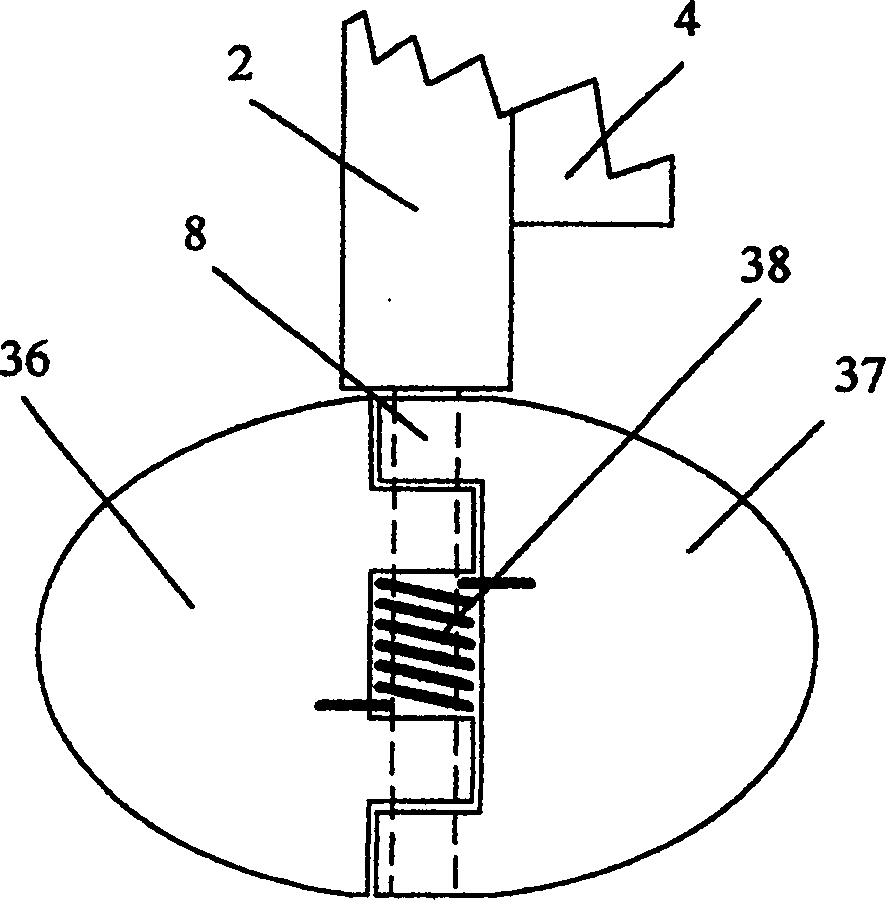

[0043] exist figure 1 Among them, the plate-shaped piston 1 is a symmetrical plate-shaped structure, there is a piston shaft on the symmetrical axis of the plate-shaped piston 1, and the plate-shaped piston 1 has a left edge 9 and a right edge 10 relative to the axis of the piston shaft. The main shaft 4 is cylindrical, and the outer circumference of the main shaft 4 has a piston frame 2, which is also cylindrical. On the circular plane of the piston frame 2, there are a plurality of piston holes 6 passing through the upper and lower planes. The radial distance of each piston hole 6 on the piston frame 2 is the same, and the plate-shaped piston 1 is supported on the piston frame 2 by the piston shaft. In the upper piston hole 6. The plate-shaped piston 1 can swing relative to the piston frame 2, and the angle at which each plate-shaped piston 1 swings determines the size of the cross-sectional area of the plate-shaped piston 1 on the planetary track.

[0044] The cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com