Novel rotary piston type engine

A technology for rotating pistons and engines, which is applied in the direction of internal combustion piston engines, combustion engines, machines/engines, etc. It can solve problems such as poor reliability and durability, low fuel utilization rate, and complicated structure, and achieve a wide range of operating speeds, The effect of high fuel utilization and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

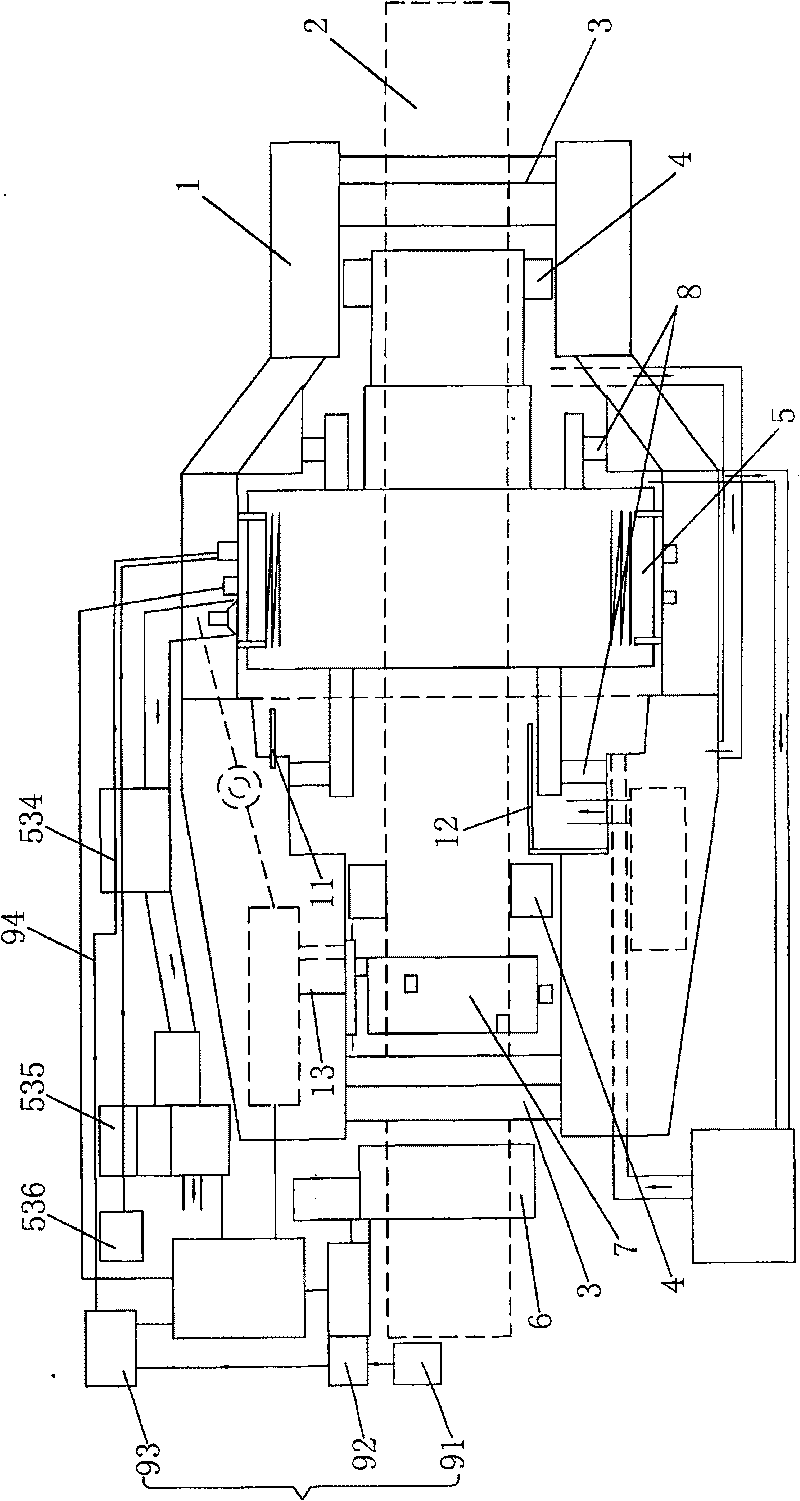

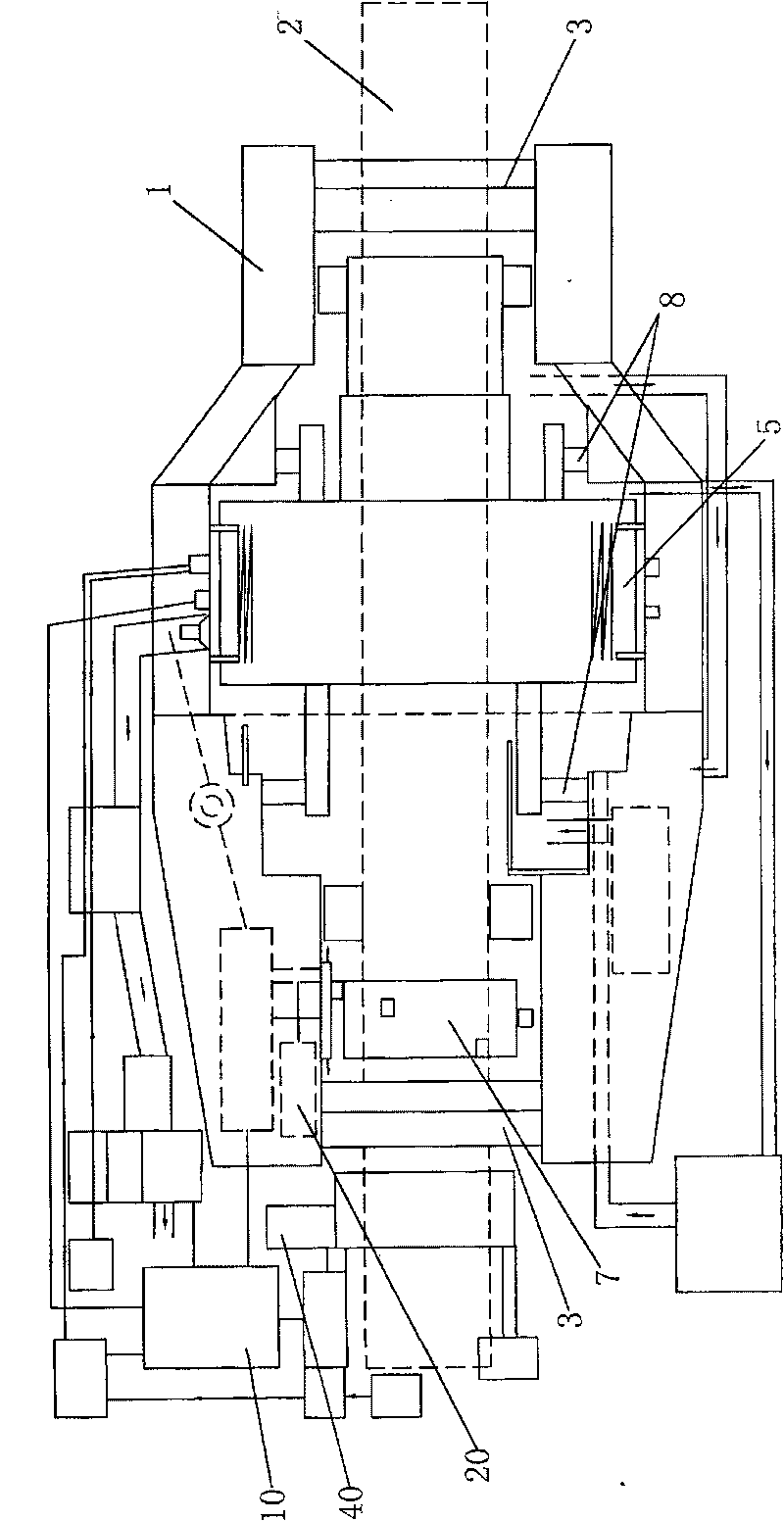

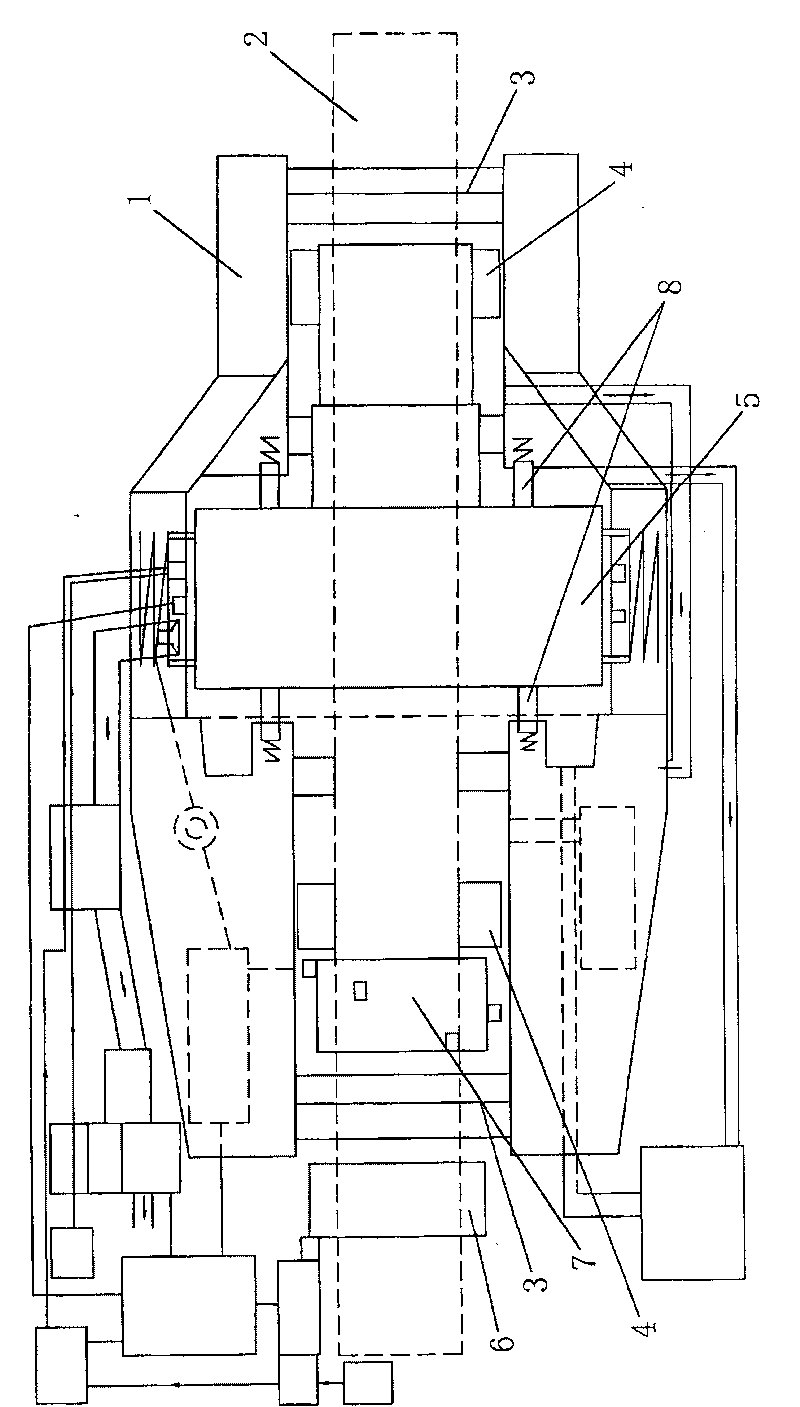

[0031] Such as figure 1 Shown, the present invention is a kind of novel rotary piston engine, and it is mainly made up of casing 1, main transmission shaft 2, oil seal 3, bearing 4, piston set wheel 5, main transmission wheel 6, cam timing wheel 7.

[0032] The piston set wheel 5 is sleeved on the main transmission shaft 2 and located in the inner cavity of the casing 1, and the main transmission shaft 2 and the two sides of the piston set wheel 5 are respectively sleeved with bearings 4 . Most of the main transmission shaft 1 is rotatably mounted on the bearing seat in the inner cavity of the casing 1 through the bearing 3, and one end of the main transmission shaft 2 extends out of the casing 1 and is socketed with the main transmission wheel 6 to form the main transmission shaft 2 power output section. Oil seals 3 are respectively installed on the outer sides of the two bearings 4 and at the two outlets of the inner chamber of the casing 1; The 7 groups of cam timing whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com