A multi-mode drive system for a hybrid vehicle

A hybrid vehicle and drive system technology, which is applied to the layout of multiple different prime movers of hybrid vehicles and general-purpose power plants, and motor vehicles, can solve the problems that are not conducive to reducing vehicle fuel consumption, vehicle economy, and structural efficiency. Problems such as simple function mode to achieve the effect of improving vehicle economy, reducing vehicle fuel consumption, and high space utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

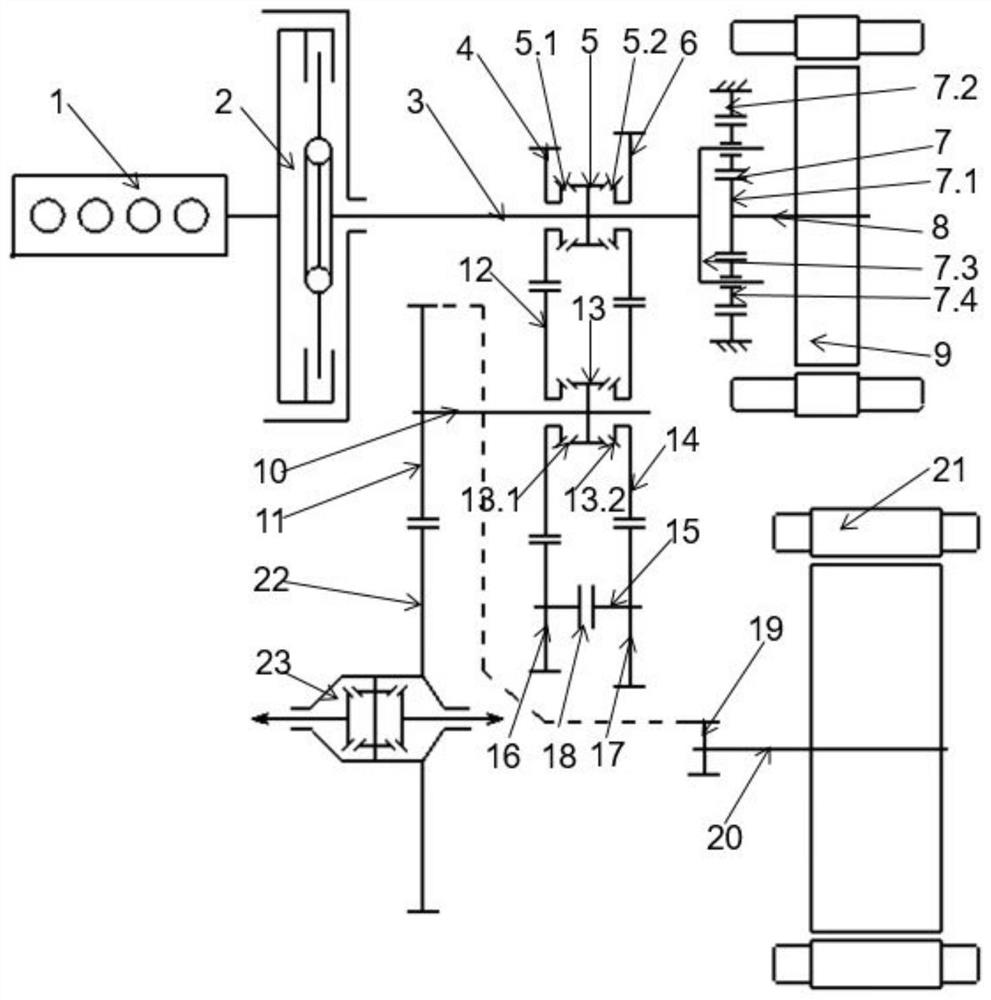

[0012] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

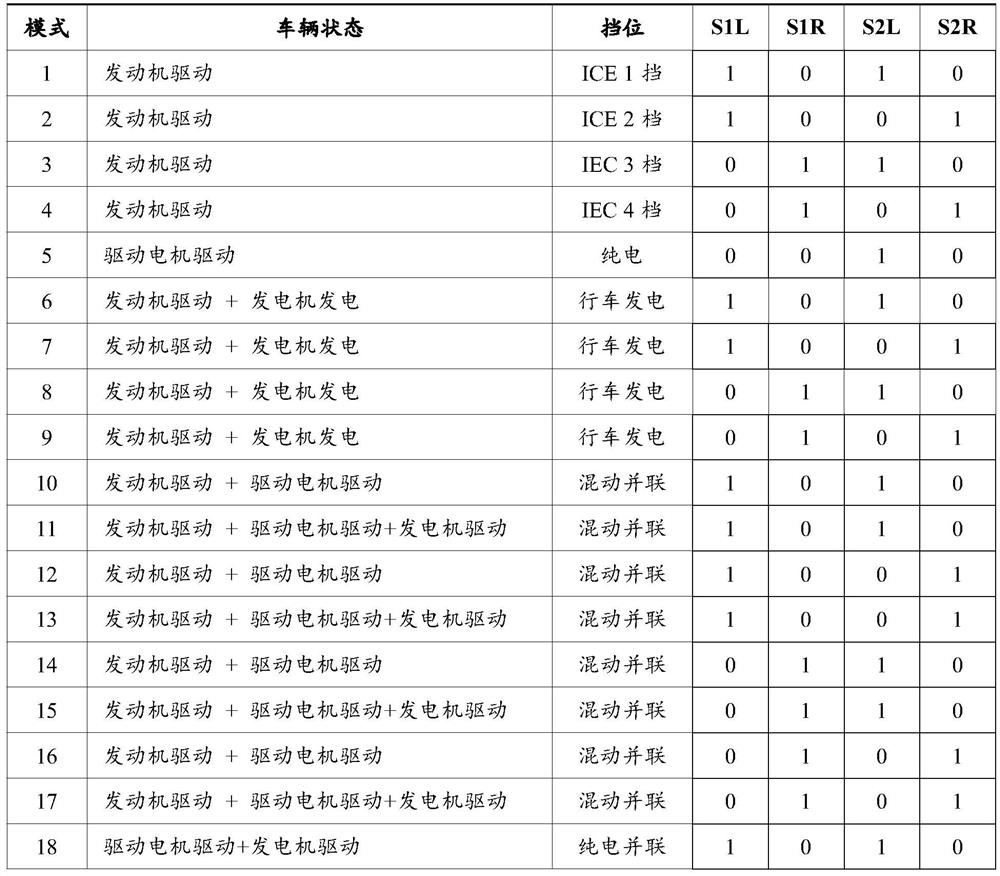

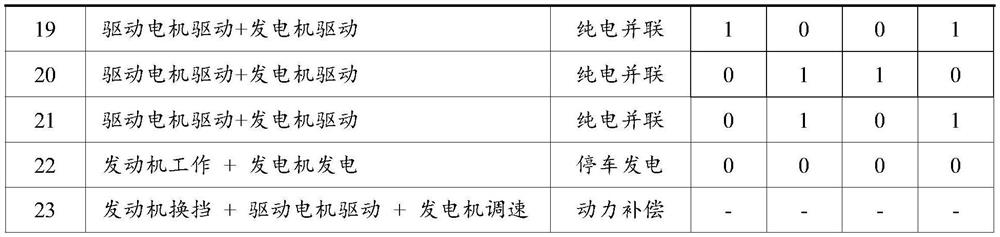

[0013] like figure 1 As shown, a multi-speed hybrid transmission, a multi-mode drive system of a hybrid vehicle, includes an engine 1, a generator 9, a drive motor 21, a planetary gear mechanism 7, an input shaft 3, a generator input shaft 8, Intermediate shaft 15, drive motor output shaft 20, output shaft 10 and differential 23, the engine is connected to the input shaft through the torsional shock absorber 2, the input shaft is coaxially arranged with the generator input shaft, and the drive motor output shaft, the intermediate shaft and the output shafts are arranged parallel to each other. The planetary gear mechanism includes a sun gear 7.1, an outer ring gear 7.2, a planetary carrier 7.3 and a planetary gear 7.4. The sun gear is installed on the input shaft of the generator, and the end of the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com