Zero-sequence current suppression method for open-winding permanent magnet synchronous motor system powered by double inverters

A permanent magnet synchronous motor, open winding technology, applied in motor generator control, electronic commutation motor control, AC motor control, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

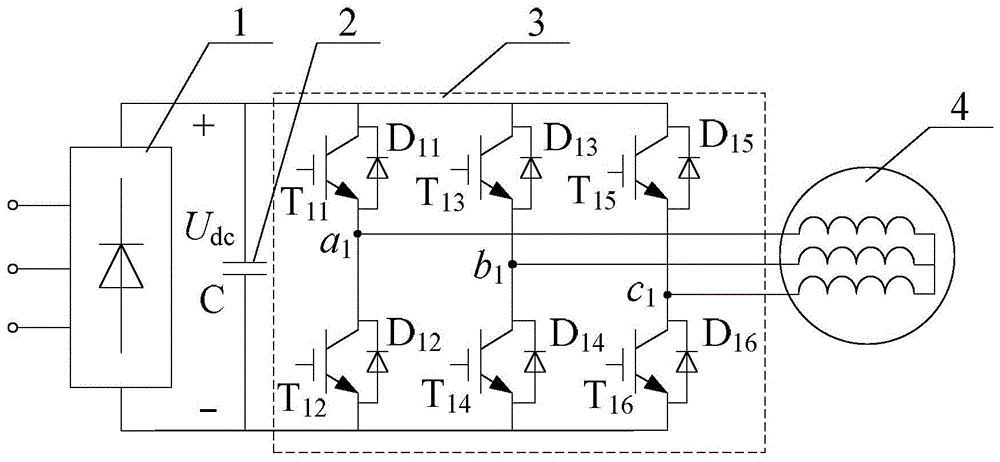

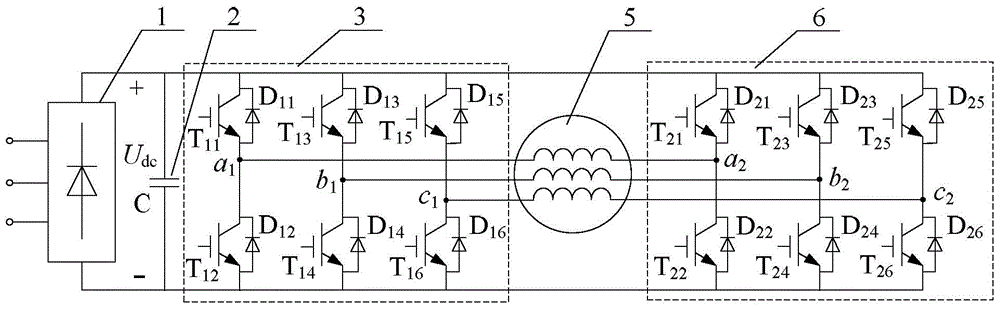

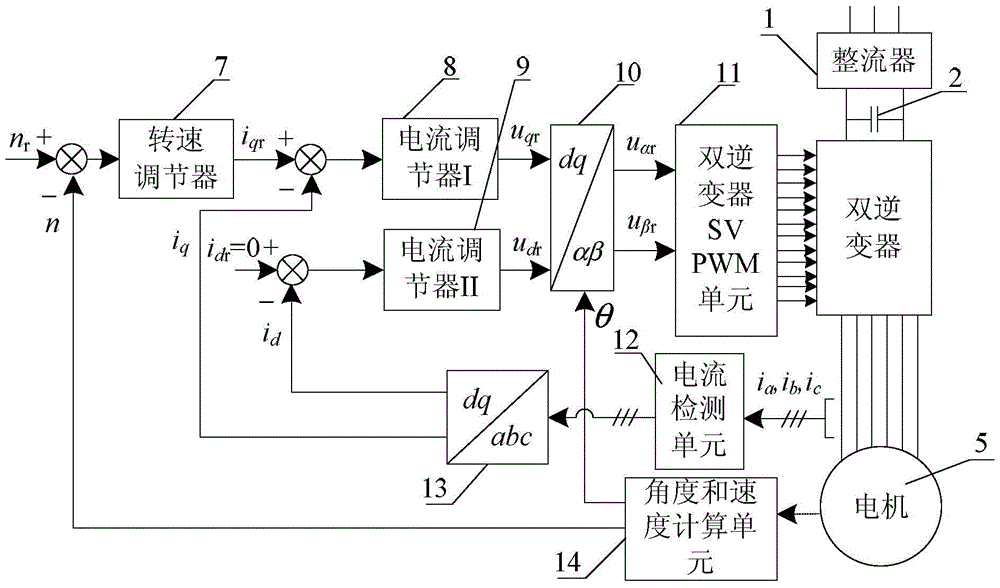

[0041] Specific implementation mode one: the following combination Figure 2 to Figure 8 Describe this embodiment, the zero-sequence current suppression method of the open-winding permanent magnet synchronous motor system powered by double inverters described in this embodiment, it is realized based on the open-type winding permanent magnet synchronous motor control system,

[0042] The motor control system includes a speed regulator 7, a current regulator I8, a current regulator II9, a dq-αβ coordinate transformation unit 10, a double inverter SVPWM unit 11, a current detection unit 12, an abc-dq coordinate transformation unit 13 and an angle with the speed calculation unit 14,

[0043] Its control method is: motor given speed n r After making a difference with the actual motor speed calculated by the angle and speed calculation unit 14, the given i of the q-axis current is generated by the speed regulator 7 qr , the given i of the q-axis current qr and the q-axis current ...

specific Embodiment approach 2

[0053] Specific implementation mode two: this implementation mode further explains implementation mode one, and the transformation formula of the abc-dq0 coordinate transformation unit 13-1 is:

[0054]

[0055] where i a is the current value of phase A at the motor input terminal, i b is the B-phase current value at the motor input terminal, i c is the C-phase current value of the motor input terminal.

specific Embodiment approach 3

[0056] Specific implementation mode three: the following combination Figure 2 to Figure 11 This embodiment will be described. This embodiment will further describe the first embodiment. The dual-inverter SVPWM unit 11 according to the α-axis voltage reference value u αr , β-axis voltage reference value u βr and the desired motor zero-sequence voltage reference value u 0r Generate 12 switching signals of the double inverter, so that the actual zero-sequence voltage u of the output of the double inverter 0 Approaching to the desired motor zero-sequence voltage reference value u 0r The specific implementation method is:

[0057] The dual inverters are inverter I3 and inverter II6, and the voltage vector U output by the dual inverters passes through the voltage vector U output by inverter I3 1 Subtract the voltage vector U of the inverter II6 output 2 get:

[0058] U=U 1 –U 2 ;

[0059] According to the triangular rule of vector synthesis, the spatial distribution diagra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com