Monodisperse large-grain-diameter and high-stability acid silica sol and preparation method thereof

A technology of acidic silica sol and high stability, which is applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc. It can solve the problems of poor stability, difficulty in controlling the particle size of acidic silica sol, large dispersion, etc., and achieve short production cycle , Facilitate large-scale industrial production and increase the effect of steric hindrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

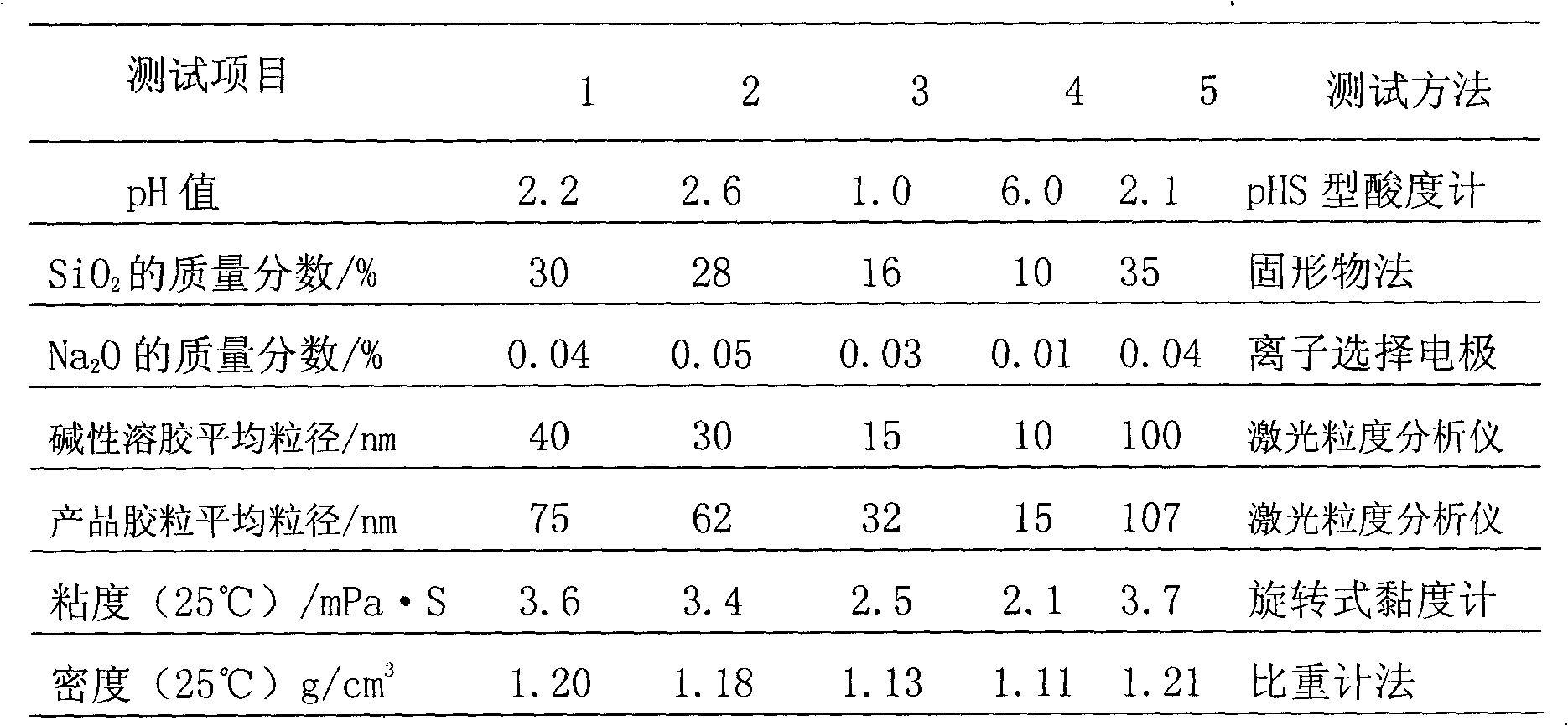

Examples

preparation example Construction

[0027] The preparation steps of the present invention are as follows:

[0028] (1) Dilute industrial sodium ions with deionized water to obtain a water glass solution with a concentration of 1-10%, carry out an exchange reaction through a styrene-based strongly acidic cation exchange resin, remove sodium ions and other cationic impurities, and obtain a concentration of 1 -10% active silicic acid solution,

[0029] (2) in the 100ml water glass solution that the pH value is 8-11, the concentration under boiling state is 1-10%, add dropwise the active silicic acid solution that 50-300ml step (1) prepares, by adding 0.3 -2ml alkaline solution, control the pH value in the range of 8-10, cool after the reaction, and age for 2-6 hours to obtain the primary mother liquor of silica sol, the concentration is 1-10%,

[0030] The alkaline solution is one or more of sodium hydroxide, ammonia water, and sodium carbonate; the concentration of sodium hydroxide, ammonia water, and sodium carb...

Embodiment 1

[0040] (1) Dilute industrial sodium ions with deionized water to obtain a concentration of 6% water glass solution, carry out exchange reaction by styrene series strongly acidic cation exchange resin, remove sodium ions and other cationic impurities, and obtain a concentration of 5% Active silicic acid solution,

[0041](2) in the 100ml water glass solution that the pH value is 10, the concentration under boiling state is 6%, add dropwise the active silicic acid solution that 150ml step (1) prepares, by adding 0.5ml sodium hydroxide (1mol / L) and 0.5ml ammoniacal liquor (1mol / L), control the pH value at about 10, cool after the reaction, and age for 6 hours to obtain the primary mother liquor of silica sol, with a concentration of 6%.

[0042] (3) Get the primary mother liquor prepared by 100ml to heat under normal pressure and keep boiling and evaporating, add dropwise the active silicic acid solution prepared by 150ml step (1) again under stirring, by adding 0.5ml sodium hyd...

Embodiment 2

[0046] (1) Dilute industrial sodium ions with deionized water to obtain a concentration of 4% water glass solution, carry out exchange reaction by styrene series strongly acidic cation exchange resin, remove sodium ions and other cationic impurities, and obtain a concentration of 3.5% Active silicic acid solution.

[0047] (2) in the 100ml water glass solution that the pH value is 9, the concentration under boiling state is 4%, drip the active silicic acid solution that 300ml step (1) prepares, by adding 0.3ml sodium carbonate (1mol / L) and 0.5ml ammoniacal liquor (1mol / L), control the pH value at about 9, cool after the reaction, and age for 4 hours to obtain a primary mother liquor of silica sol, with a concentration of 4%.

[0048] (3) Get the primary mother liquor prepared by 100ml to heat under normal pressure and keep boiling and evaporating, add dropwise the active silicic acid solution prepared by 300ml step (1) again under stirring, and add 0.5ml sodium carbonate (1mo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com