Method for producing methyl methoxyacetate by methylal vapor-phase carbonylation by using supported heteropoly acid catalyst

A technology of methyl methoxyacetate and gas-phase carbonylation, applied in the directions of carbon monoxide or formate reaction preparation, organic chemistry, etc., can solve the problems of less research on ethylene glycol precursors, etc., and is beneficial to large-scale industrial production, catalysis High efficiency and easy separation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] 5%H 3 PW 12 o 40 / SiO 2 Catalyst preparation process is as follows: with concentration is the phosphotungstic acid aqueous solution of 6% by weight, with SiO 2 As a carrier, the volume of the impregnation solution is the same as the pore volume of the carrier, the carrier is mixed with the impregnation solution, and after mixing uniformly, it is left at room temperature for 10 hours to obtain the carrier impregnated with the heteropolyacid as a sample, and the sample Dry at 120°C and bake at 350°C for 4 hours to prepare catalyst samples. The catalyst number is 1.

[0045] 5%H 3 PW 12 o 40 / SiO 2 Catalyst preparation process is as follows: with concentration is the phosphotungstic acid aqueous solution of 6% by weight, with SiO 2 As a carrier, the volume of the impregnation solution is the same as the pore volume of the carrier, the carrier is mixed with the impregnation solution, and after mixing uniformly, it is left at room temperature for 20 hours to obtain ...

Embodiment 2

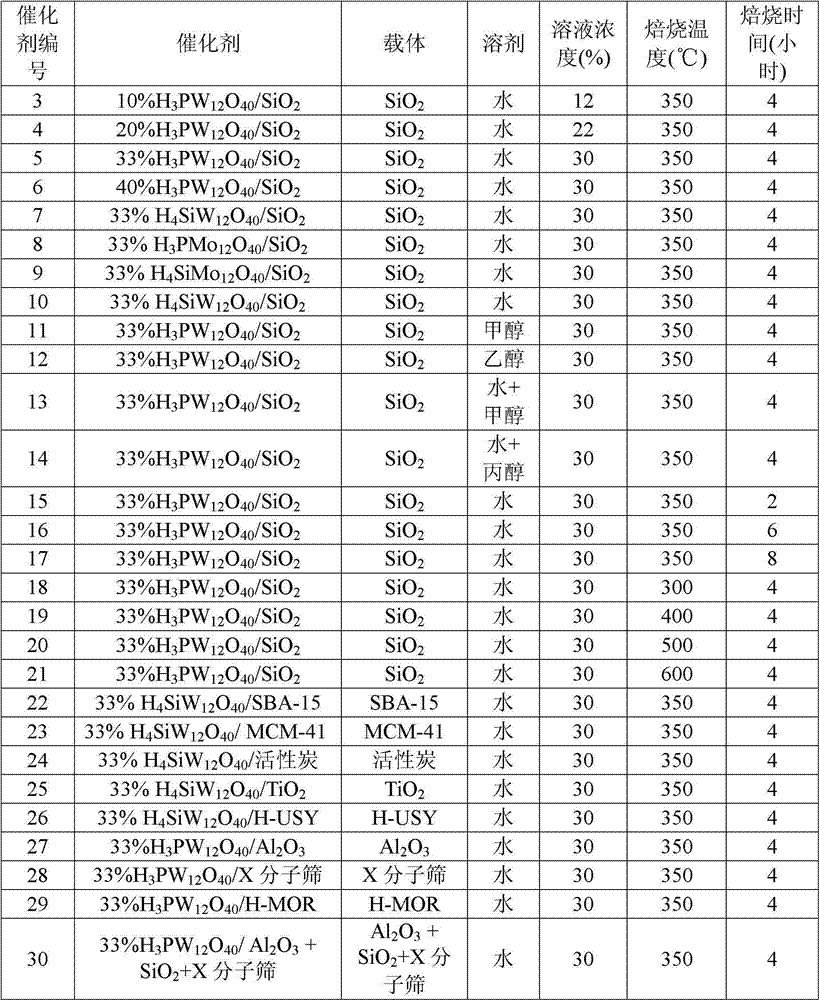

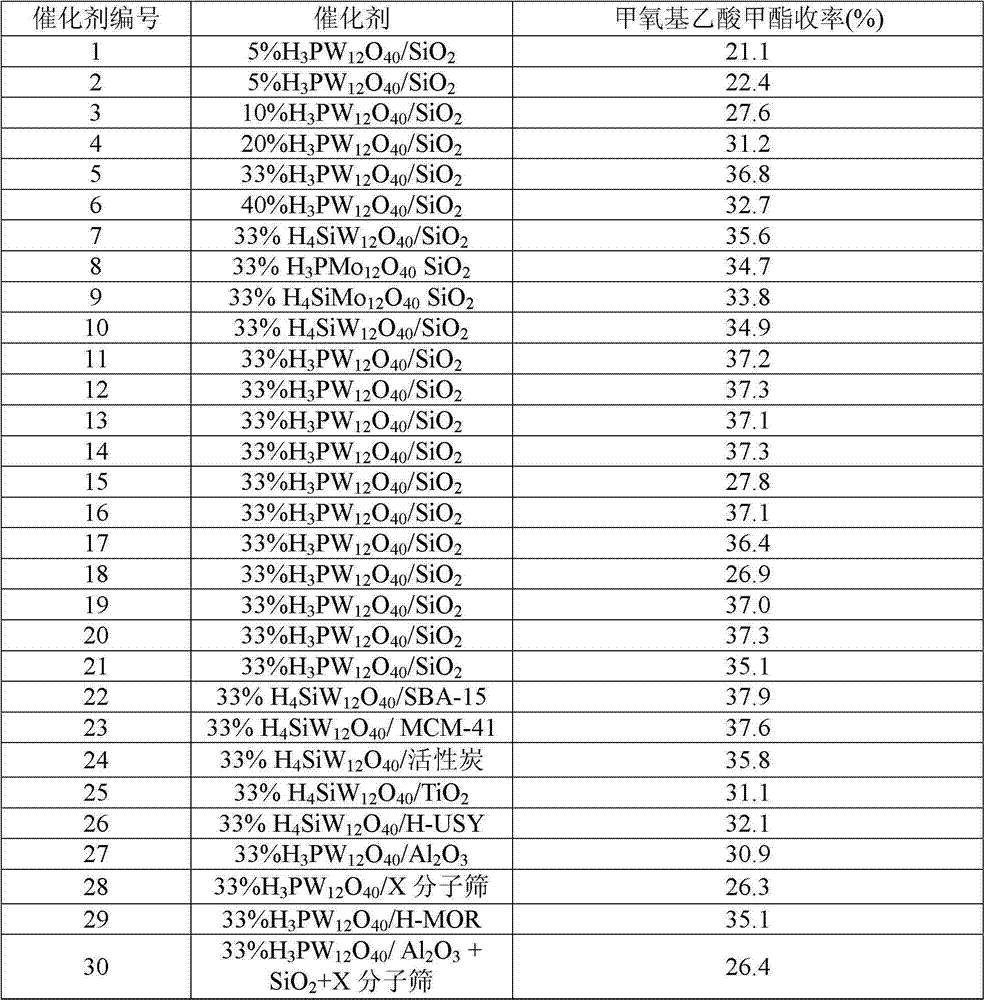

[0053] Experiments on Vapor Phase Carbonylation of Methylal over Various Catalysts

[0054] A fixed-bed reactor with an inner diameter of 6mm is filled with 0.5g of one of the catalysts 1 to 30, the reaction pressure is 1.5MPa, the reaction temperature is 110°C, the space velocity of the gas phase medium containing CO is 100ml / min, and the CO in the gas phase medium The ratio is 60%, the additional gas of the CO-containing gas phase is hydrogen, and the CO / DMM molar ratio is 150. After the reaction was stable, the reaction raw materials and products were analyzed by online chromatography. The results are shown in Table 3.

[0055] Table 3: Experiments on gas phase carbonylation of methylal over various catalysts

[0056]

Embodiment 3

[0058] 33%H at different temperatures 3 PW 12 o 40 / SiO 2 Vapor Phase Carbonylation of Methylal over Catalyst

[0059] A fixed bed reactor with an inner diameter of 6 mm is filled with 0.5 g of catalyst, the reaction pressure is 1.5 MPa, the space velocity of the gas phase medium containing CO is 100 ml / min, the proportion of CO in the gas phase medium is 60%, and the other gas containing CO gas phase is Hydrogen with a CO / DMM molar ratio of 150. After the reaction was stable, the reaction raw materials and products were analyzed by online chromatography. The results are shown in Table 4.

[0060] Table 4

[0061] temperature(℃) Yield of methyl methoxyacetate (%) 80 32.9 100 35.2 130 38.7 180 35.8

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com