Hydration heat regulating and controlling material as well as preparation method and application thereof

A heat of hydration and cementitious material technology, applied in the field of concrete admixtures, can solve the problems of severe retardation, strength reduction, limited ability to suppress heat of hydration, etc., and achieve the effect of simple and easy preparation method and improved inhibition ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

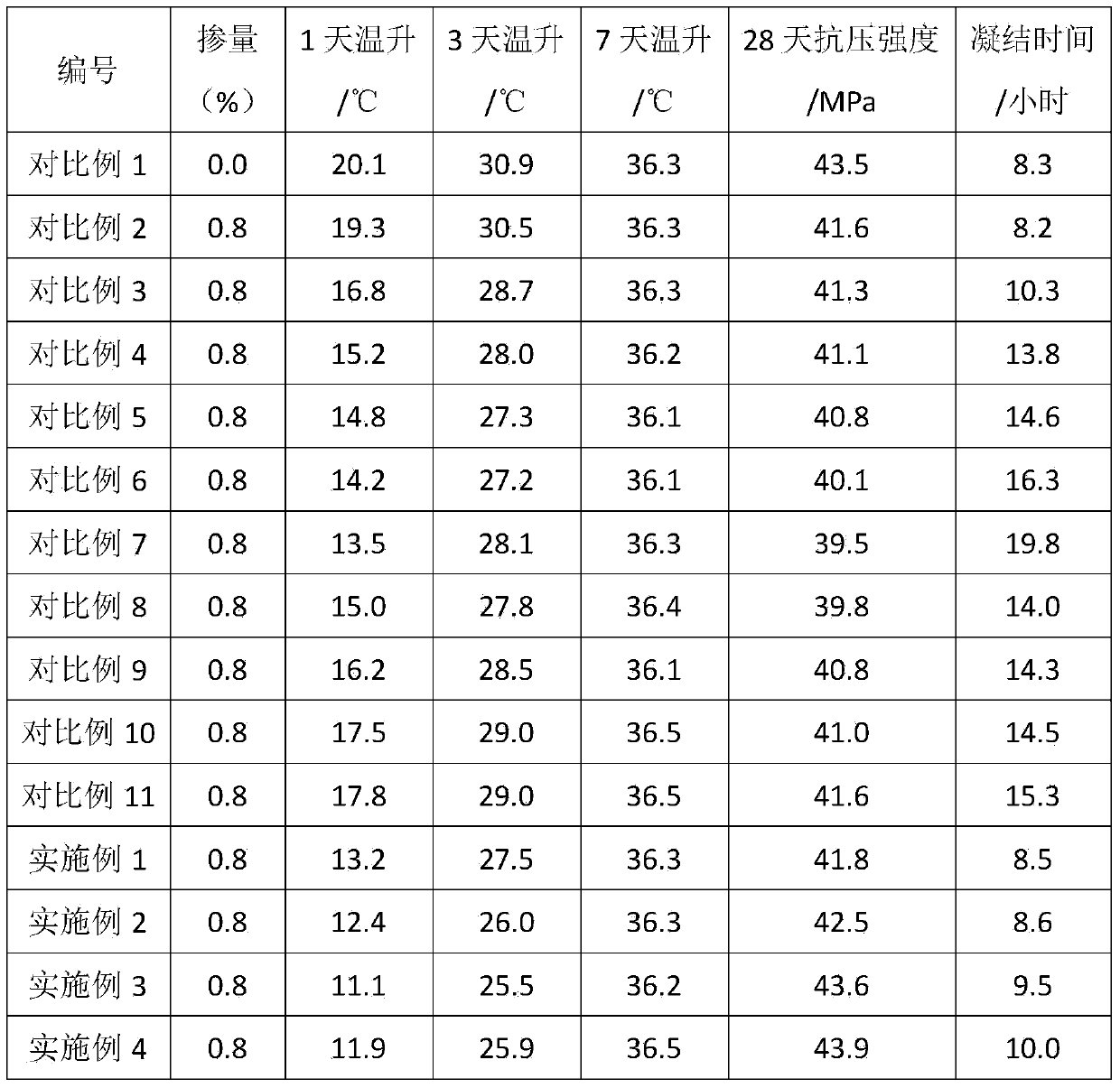

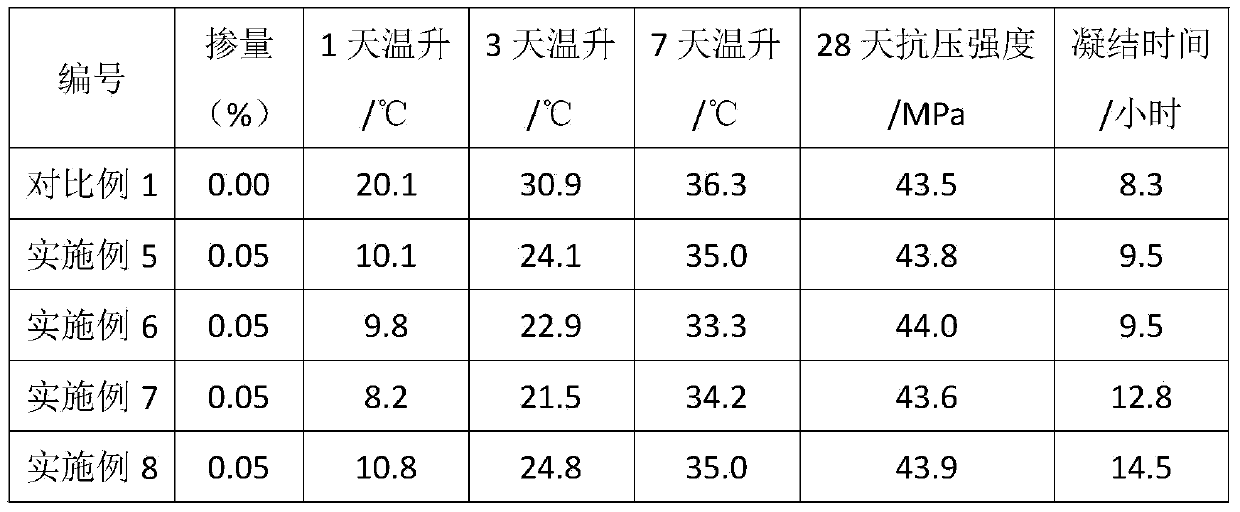

Examples

Embodiment 1

[0035] Add 1,000g of dextrin with a number average molecular weight of 84,000g / mol and a size of 700um to 2,000g of water, add 0.12g of epichlorohydrin, adjust the pH to 10 with NaOH, raise the temperature to 45°C for 12 hours, and obtain a white powder after separation and drying. That is, the dextrin described in the present invention.

Embodiment 2

[0037] Except that the size of the dextrin used is 100um, others are consistent with Example 1.

Embodiment 3

[0039] Except that the size of the dextrin used is 10um, others are consistent with Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com