Control method of semiconductor packaging control system

A technology of control system and control method, applied in the direction of control system, vector control system, control electromechanical brake, etc., to achieve the effect of ensuring performance and improving suppression ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

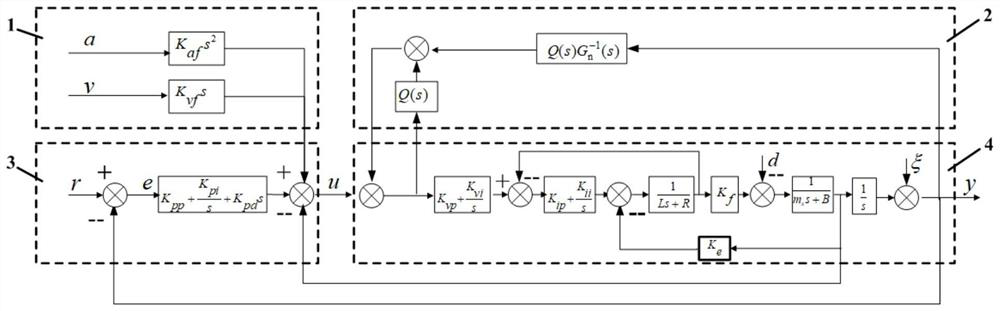

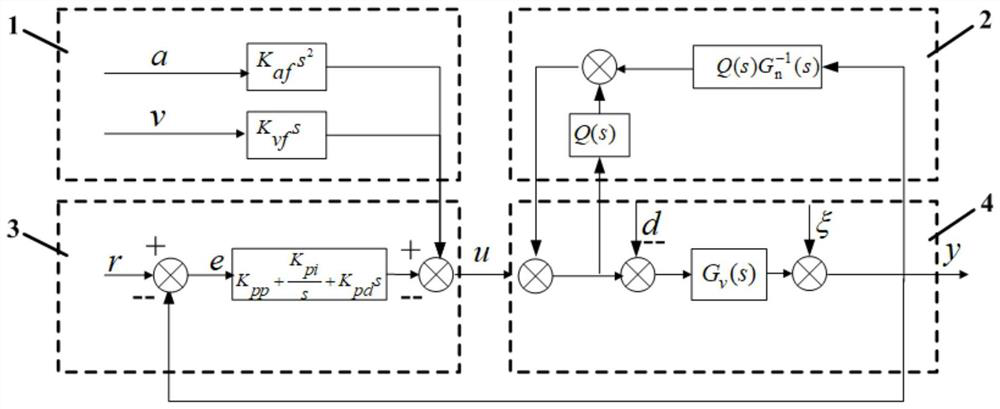

[0261] According to a specific embodiment of the present invention, the steps of establishing a transfer function adding a dedicated disturbance observer in the control method of the semiconductor packaging control system of the present invention will be described in detail.

[0262] According to a specific embodiment of the present invention, establishing the transfer function of adding a dedicated interference observer specifically includes the following steps:

[0263] According to the principle of the interference observer, the establishment of the interference observer includes the following steps:

[0264] Set u as the reference input of the basic model with disturbance observer, and its value is the obtained velocity acceleration look-ahead K af the s 2 、K vf the s 2 and position loop control output G PID sum of (s);

[0265]Let d be the low-frequency interference of the system, ξ be the high-frequency interference of the system, Q(s) be the filter, G V (s) is the...

Embodiment 2

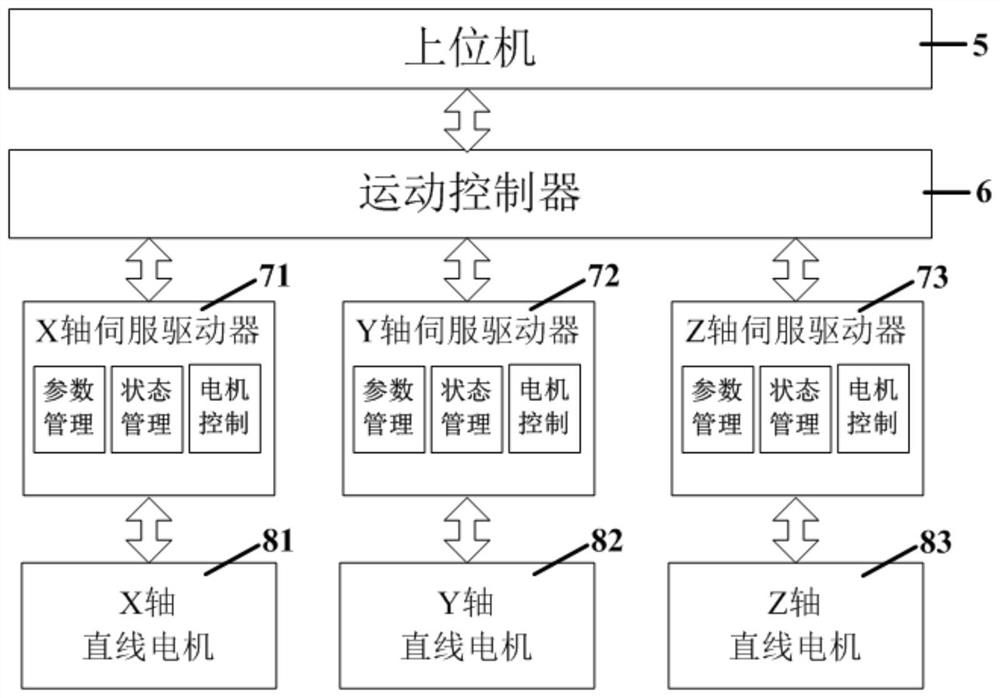

[0284] According to a specific embodiment of the present invention, the steps of establishing a solidified control kernel function based on the linear motor mathematical model, current loop and speed loop in the control method of the semiconductor packaging control system of the present invention will be described in detail.

[0285] Based on the linear motor mathematical model, current loop and speed loop, the solidified control kernel function G is established V (s) specifically include the following steps:

[0286] Establish the mathematical model of the linear motor platform in the control system, the formula is as follows:

[0287]

[0288] in,

[0289] G M The output of the linear motor platform in the control system;

[0290] L is the armature inductance of the linear motor (unit: mH);

[0291] R is the linear motor armature resistance (unit: Ω);

[0292] K f is the force constant of the linear motor (unit: N / A);

[0293] m is the moving mass of the linear mot...

Embodiment 3

[0325] According to a specific embodiment of the present invention, in the control method of the semiconductor encapsulation control system of the present invention, based on curing control kernel function G V (s), the steps of establishing the transfer function of the position loop using PID control are described in detail.

[0326] Based on the solidified control kernel function G V (s), establish the position loop transfer function that adopts PID control, specifically comprise the following steps:

[0327] The PID control expression of the position loop is:

[0328]

[0329] Establish the transfer function G of the position loop controlled by PID PID (S) is:

[0330]

[0331] in,

[0332] K pp is the proportional coefficient of the position ring;

[0333] K pi is the integral coefficient of the position loop;

[0334] K pd is the differential coefficient of the position loop;

[0335] G p Output for the position loop;

[0336] D. 4 =K pp B 2 ;

[0337...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com