Preparation method of polyether modified organic silicon

A polyether modification and organosilicon technology, which can be applied to coatings and other directions, can solve the problem of adding a large amount of organic solvents, and achieve the effects of easy control, low cost, and large-scale industrial production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

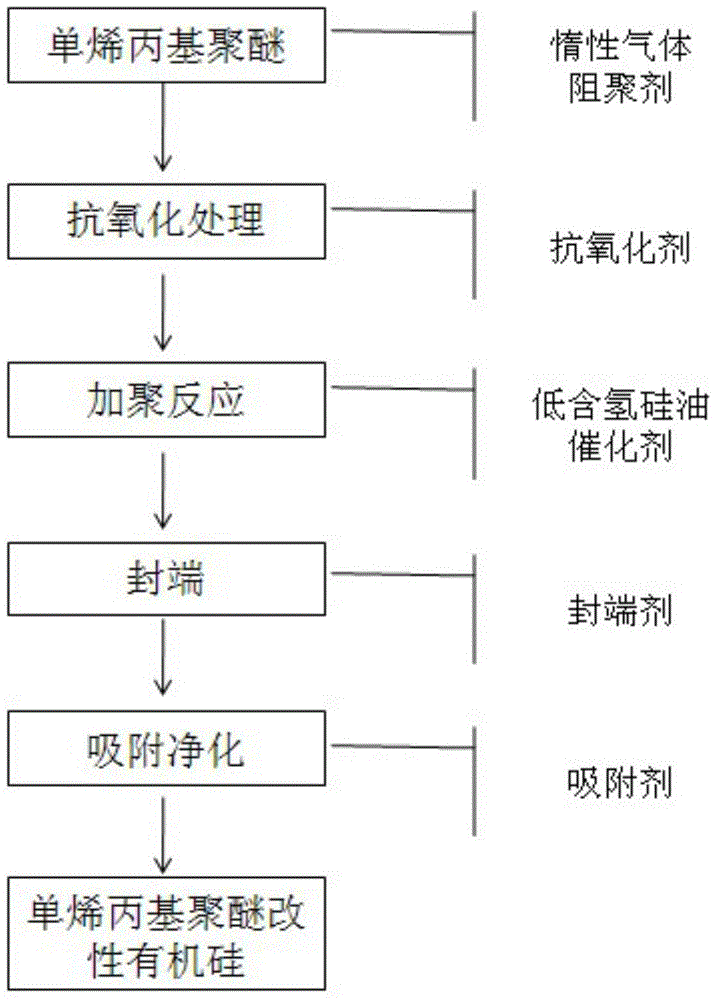

[0032] as attached figure 1 As shown, the embodiment of the present invention provides a preparation method of polyether-modified silicone, and the preparation method specifically includes the following steps:

[0033] Under the condition that inert gas and polymerization inhibitor exist, the monoallyl polyether is reacted with an antioxidant, and the monoallyl polyether is subjected to antioxidant treatment.

[0034] During the storage process of monoallyl polyether, if it is in contact with air for too long, peroxide groups will be generated, which will hinder the catalysis of the catalyst in the subsequent monoallyl polyether polyaddition reaction and reduce the reaction efficiency , as a preference, so the embodiment of the present invention uses at least one of ascorbic acid, propyl gallate, citrate and ascorbyl palmitate as an antioxidant to first carry out antioxidant treatment on monoallyl polyether. The anti-oxidation treatment is to add an anti-oxidant to the monoal...

Embodiment 2

[0058] First, N was passed into a 250ml four-necked glass flask. 2 , and then convert the structure to CH 2 =CHCH 2 O(C 2 h 4 O) 6 H's monoallyl polyether 100g, propyl gallate 0.1g, polymerization inhibitor tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionate] pentaerythritol ester (commercial brand "anti- Oxygen agent 1010") 0.1g was added to the four-necked flask, stirred and heated to 80°C, and reacted for 1h. Then, add 138g of low-hydrogen silicone oil (hydrogen content 0.15%, viscosity 13cps) and 0.933g isopropanol solution of chloroplatinic acid with a mass fraction of 2% to the four-necked flask, the reactant starts to change from turbid to transparent, continue The heat preservation reaction was carried out for 2 hours, and the Si-H peak was detected by infrared absorption spectrum to stop the polyaddition reaction. Heat the reaction system after the polyaddition reaction to 90°C, add 35g of acetic anhydride, keep it warm for 2 hours, and detect through IR ...

Embodiment 3

[0062] In a 250ml four-necked glass flask, N 2 , and join the structure as CH 2 =CHCH 2 O(C 2 h 4 O) 6 100g of monoallyl polyether of H, 3g of ascorbyl palmitate, 0.3g of benzoquinone polymerization inhibitor, stirring and raising the temperature to 60°C, and keeping the temperature for 3h. Then add 0.933g of platinum solution with a mass fraction of 2% to the above reaction system, stir evenly, and add 138g of low-hydrogen silicone oil (hydrogen content 0.15%, viscosity 13cps) dropwise within 1h, the reactant changes from turbid to transparent , the temperature was raised to 90° C. and the reaction was continued for 3 h. When the Si-H peak disappeared by IR detection, the reaction was stopped. Raise the temperature to 100°C, add 35g of acetic anhydride, and react for 1h. When the -OH peak disappears through IR detection, the reaction system is distilled under reduced pressure to distill off excess acetic anhydride and other low-boiling substances to obtain a yellow to br...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com