690 alloy U-shaped heat transfer pipe production line for nuclear power evaporator

A nuclear power evaporator and production line technology, applied in the production line of 690 alloy U-shaped heat transfer tubes for nuclear power evaporators, to achieve the effects of reducing the possibility of pipe pollution, product quality assurance, and smooth production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

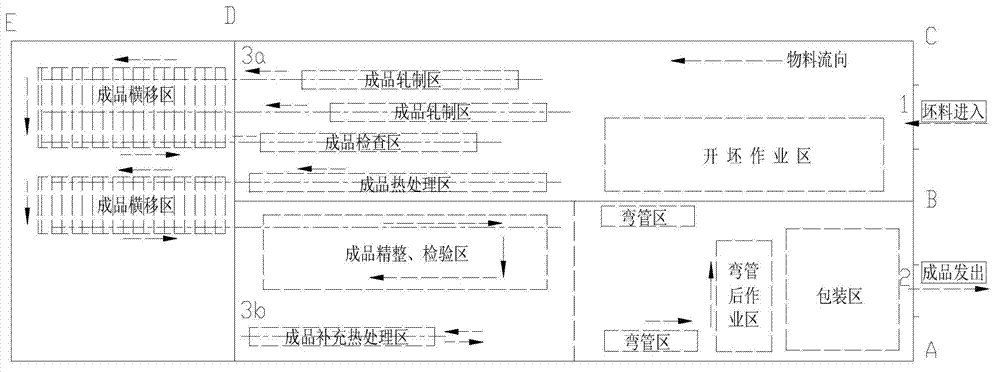

[0018] This embodiment is a production line of 690 alloy U-shaped heat transfer tubes for nuclear power evaporators. The layout of the production line is as follows: figure 1 As shown, it includes two adjacent longitudinal spanning areas AB and BC and a transverse spanning area CD which is arranged at the ends of the two adjacent longitudinal spanning areas and is adjacent to and perpendicular to the two longitudinal spanning areas, wherein the first The longitudinal span BC, the second longitudinal span AB and the transverse span CD form a "Π"-shaped production line; one end of the first longitudinal span BC is the tube blank inlet 1, and the second longitudinal span AB corresponds to the tube blank inlet. One end is the finished tube outlet 2, the adjacent end of the first longitudinal spanning area BC and the transverse spanning area CD is the intermediate pipe outlet 3a far away from the tube blank inlet, and the adjacent end of the second longitudinal spanning area AB and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com