Comprehensive stabilization treatment technology of waste incineration fly ash

A waste incineration fly ash and stabilization treatment technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve the problems of complex components, large fluctuations, and increased amount of fly ash in flue gas and fly ash, etc. Achieve the effect of avoiding unsatisfactory stabilization effect, reducing the fluctuation of physical and chemical properties, and reducing the difficulty of stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

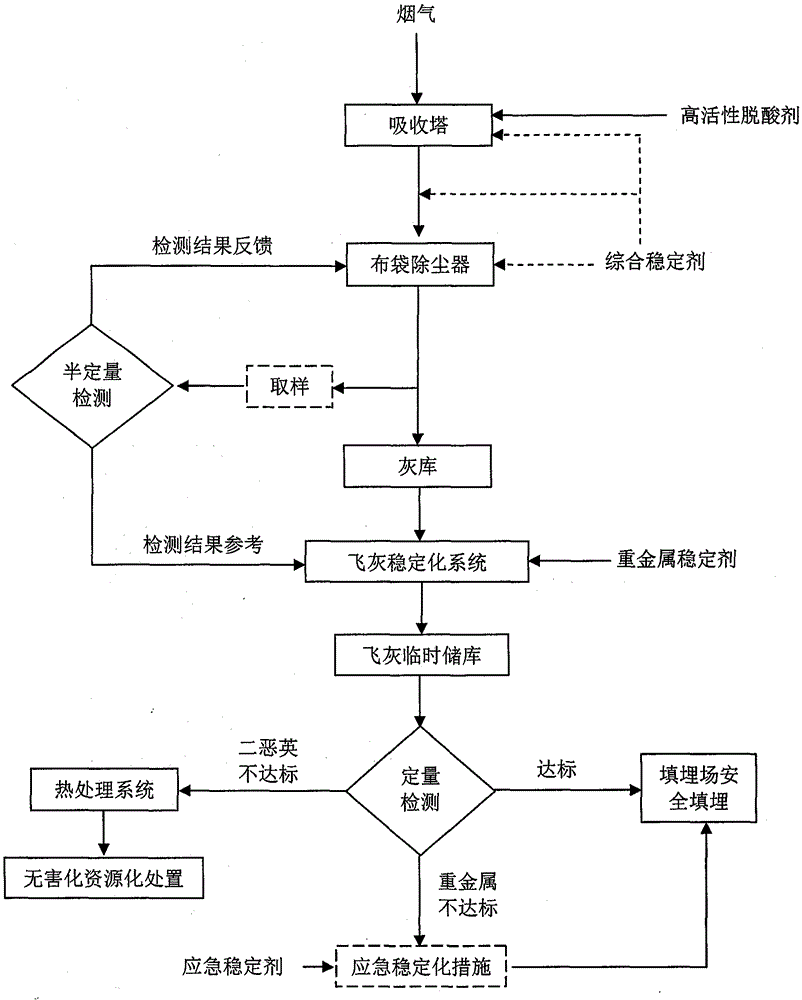

Method used

Image

Examples

Embodiment 1

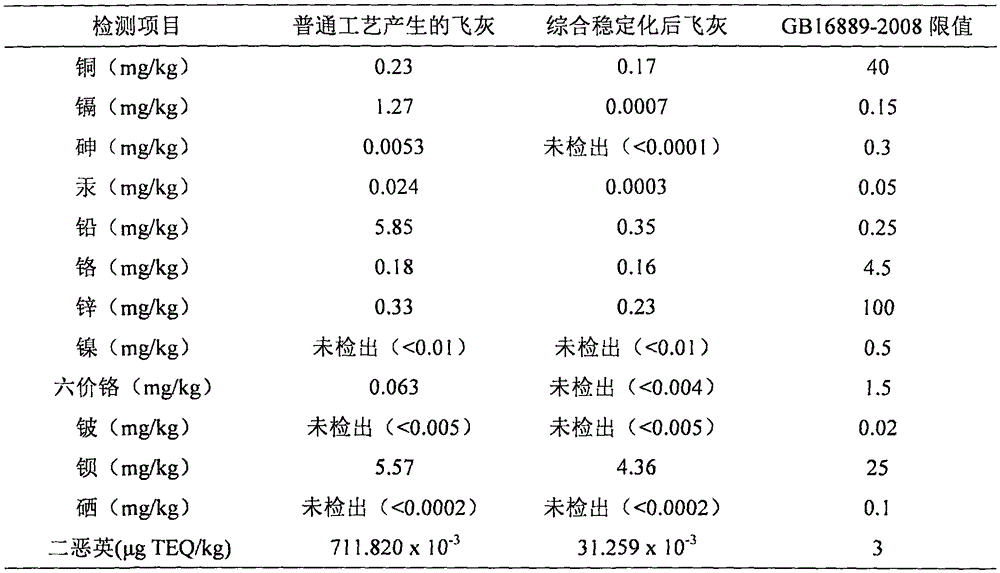

[0032] Sampling is taken at the discharge chute of the ash conveying equipment, and the heavy metal leaching toxicity of the fly ash sample exceeds the requirements of GB16889-2008 "Pollution Control Standards for Domestic Waste Landfill Sites" during on-site semi-quantitative testing, and the addition of comprehensive stabilizers should be appropriately increased Amount, and determine the amount of heavy metal stabilizer added in the fly ash stabilization system is 1.5% of the total amount of fly ash. After the fly ash is treated by the stabilization system, it enters the temporary storage, takes samples, and quantitatively detects the fly ash samples. The results are shown in Table 1. Landfill Pollution Control Standards, directly enter the domestic waste landfill for safe landfilling.

[0033] Table 1 List of heavy metal leaching toxicity and dioxin content in fly ash after comprehensive stabilization:

[0034]

[0035]Example 2

Embodiment 2

[0037] Sampling at the discharge chute of the ash conveying equipment, if the heavy metal leaching toxicity of the fly ash sample exceeds the requirements of GB16889-2008 "Pollution Control Standards for Domestic Waste Landfill Sites" during semi-quantitative testing on site, the amount of comprehensive stabilizer should be appropriately increased Addition amount, and determine the addition amount of heavy metal stabilizer in the fly ash stabilization system as 1% of the total amount of fly ash. After the fly ash has been treated by the stabilization system, it enters the temporary storage for sampling and quantitative testing of the fly ash samples. The test results are shown in Table 2. The leaching concentration of lead is still not up to the standard. During temporary storage, due to changes in environmental conditions, etc., the lead in fly ash is re-leached. Add 8% mixture of sodium phosphate and sodium polysulfide as an emergency stabilizer to fly ash that does not meet...

Embodiment 3

[0045] Sampling was taken at the discharge chute of the ash conveying equipment, and the heavy metal leaching toxicity and dioxin content of the fly ash samples did not exceed the requirements of GB16889-2008 "Pollution Control Standards for Domestic Waste Landfill Sites" during the on-site semi-quantitative testing. Directly enter the temporary storage, and take another sample for quantitative detection. The test results are shown in Table 4. The leaching concentration of heavy metals and dioxin content in fly ash all meet the requirements of GB16889-2008 "Pollution Control Standards for Domestic Waste Landfill Sites". Into the domestic waste landfill safe landfill.

[0046] Table 4 List of heavy metal leaching toxicity and dioxin content in fly ash after comprehensive stabilization:

[0047]

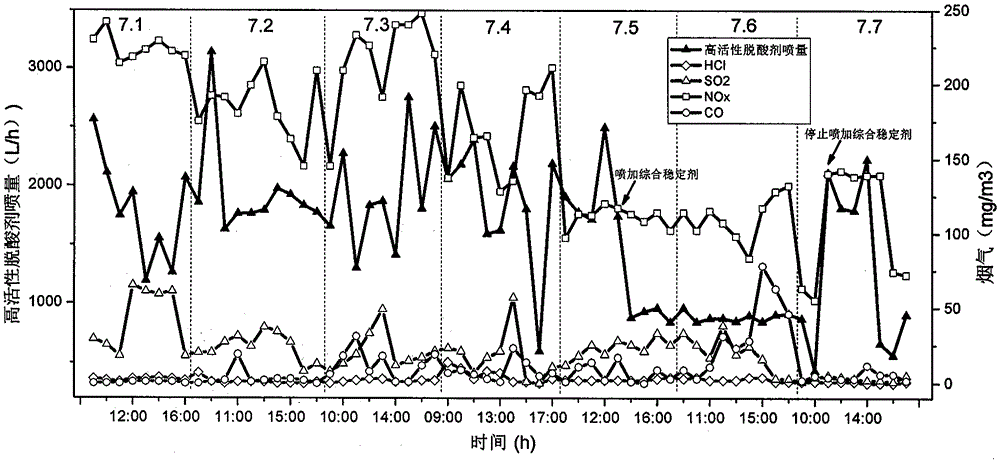

[0048] In Examples 1 to 3, the impact of high activity deacidification agent and comprehensive stabilizer spray volume on pollutants in flue gas is as follows: figure 1 shown. It ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com