Stirring equipment specially for metro mortar

A technology for mixing equipment and subway sand, applied in mixing plants, clay preparation devices, mixing operation control devices, etc., can solve problems such as failure to reflect environmental protection performance, failure to guarantee slurry quality, uncontrollable measurement, etc., to achieve transformation Fast field, small footprint, no foundation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

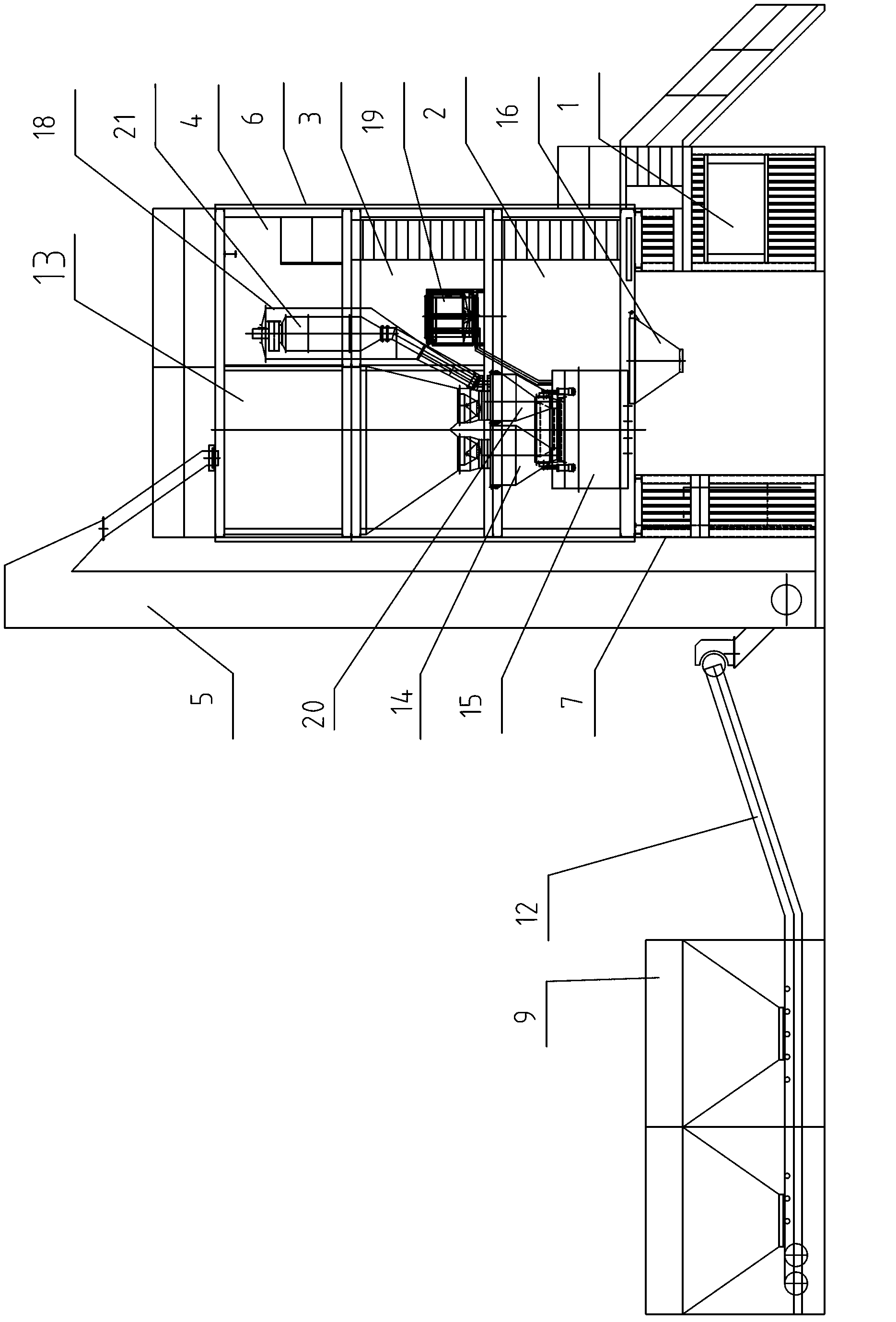

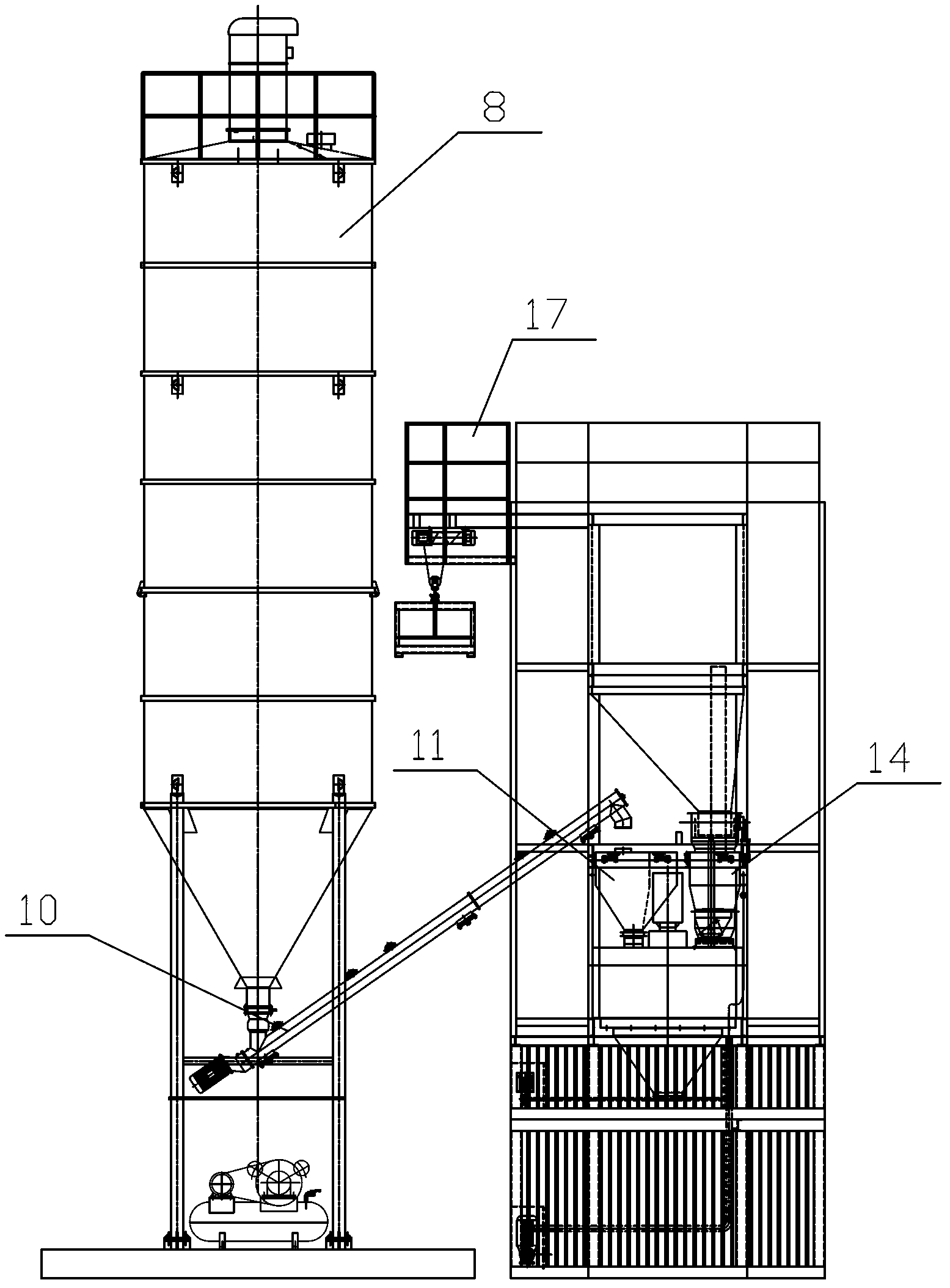

[0017] Refer to the attached figure 1 And attached figure 2 The special mixing equipment for subway mortar of the present invention is described in detail below.

[0018] The special mixing equipment for subway mortar of the present invention comprises a control room 1, a water tank and an admixture tank 7, a mixing unit 2, a metering unit 3, an aggregate storage unit 4, an aggregate batching system 9 and a powder storage system 8. The control room 1, the water tank and the additive tank 7, the stirring unit 2, the metering unit 3, and the aggregate storage unit 4 are stacked into a building body, and the control room 1, the water tank and the additive tank 7 are at the bottom, installed in On the ground, the stirring unit 2, the metering unit 3, and the aggregate storage unit 4 are set up sequentially from bottom to top, and the aggregate batching system 9 is set on the ground, and is connected with the building body through a batching belt conveyor 12. The lower part of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com