Multi-layer efficient waterproof rolled material and its manufacturing method

A waterproof membrane and high-efficiency technology, applied in waterproof membrane and its manufacturing, waterproof membrane with multi-layer waterproof base layer and its manufacturing field, can solve poor anti-aging performance, low tensile strength, waste of resources, etc. problems, to achieve the effect of improving waterproof performance and tensile strength, meeting high standard requirements, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

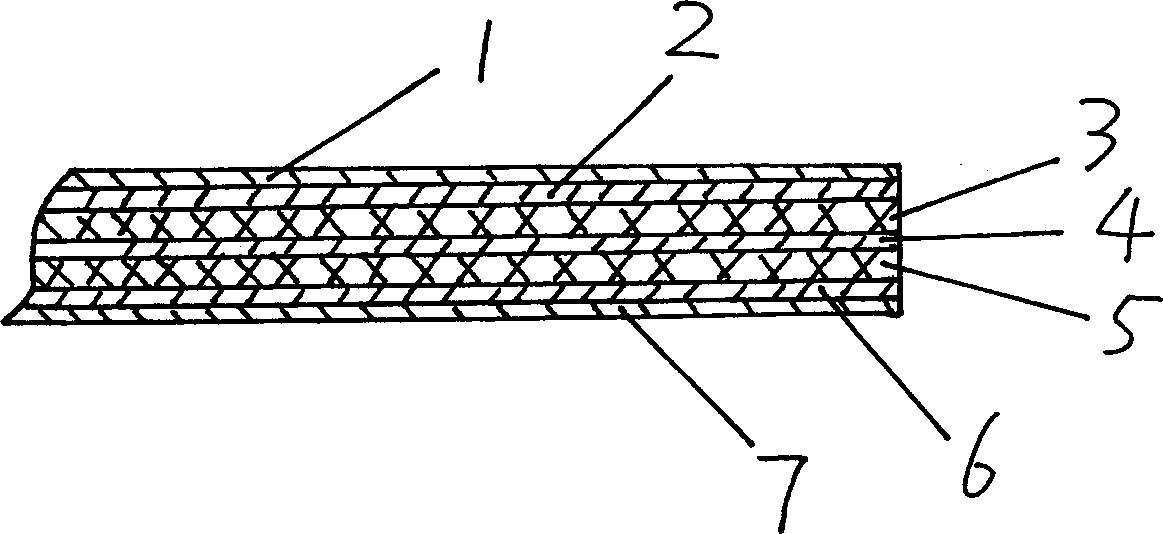

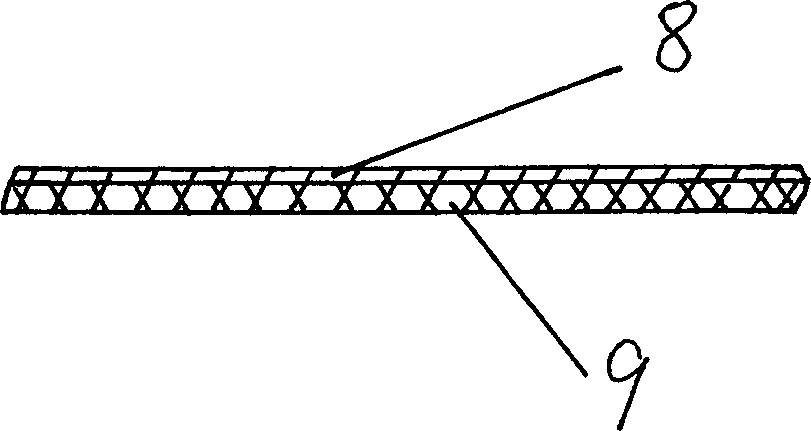

[0026] A multi-layer high-efficiency waterproof membrane composed of two layers of waterproof base layer carcass, such as figure 1 shown. The waterproof roll material is composed of the upper surface layer 1, the waterproof base layer 2, the waterproof base layer 3, the waterproof base layer 4, the waterproof base layer 5, the waterproof base layer 6 and the lower cover layer 7 sequentially. Waterproof bases 2, 4, 6 can be made of conventional asphalt waterproof bases, or asphalt waterproof bases modified by high molecular polymers, wherein the high molecular polymers can be random polypropylene, propylene, polyethylene , SBS thermoplastic elastomer, one or more of styrene-butadiene rubber. The overlying surface layer 1 can be one of fine sand, colored sand, schist, ore powder, aluminum foil, and polyethylene film. The lower covering layer 7 can be one of ore powder and polyethylene film.

[0027] The method of manufacturing a multi-layer high-efficiency waterproof membrane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com