Flame-retardant polypropylene material for cover of new energy vehicle battery pack and preparation method of flame-retardant polypropylene material

A flame retardant polypropylene and new energy vehicle technology, which is applied in the field of flame retardant polypropylene material for the upper cover of the battery pack of the new energy vehicle and its preparation field, can solve the problem that the mechanical properties and flame retardant properties of the upper cover of the battery pack of the new energy vehicle cannot be satisfied. and lightweight problems, to achieve the effect of improving mechanical properties and reducing product density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

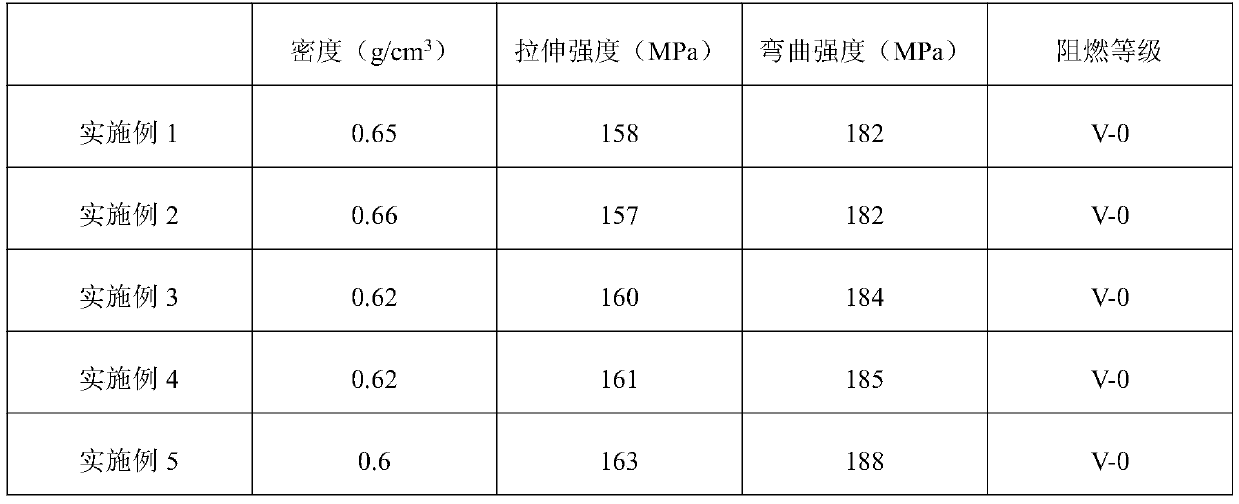

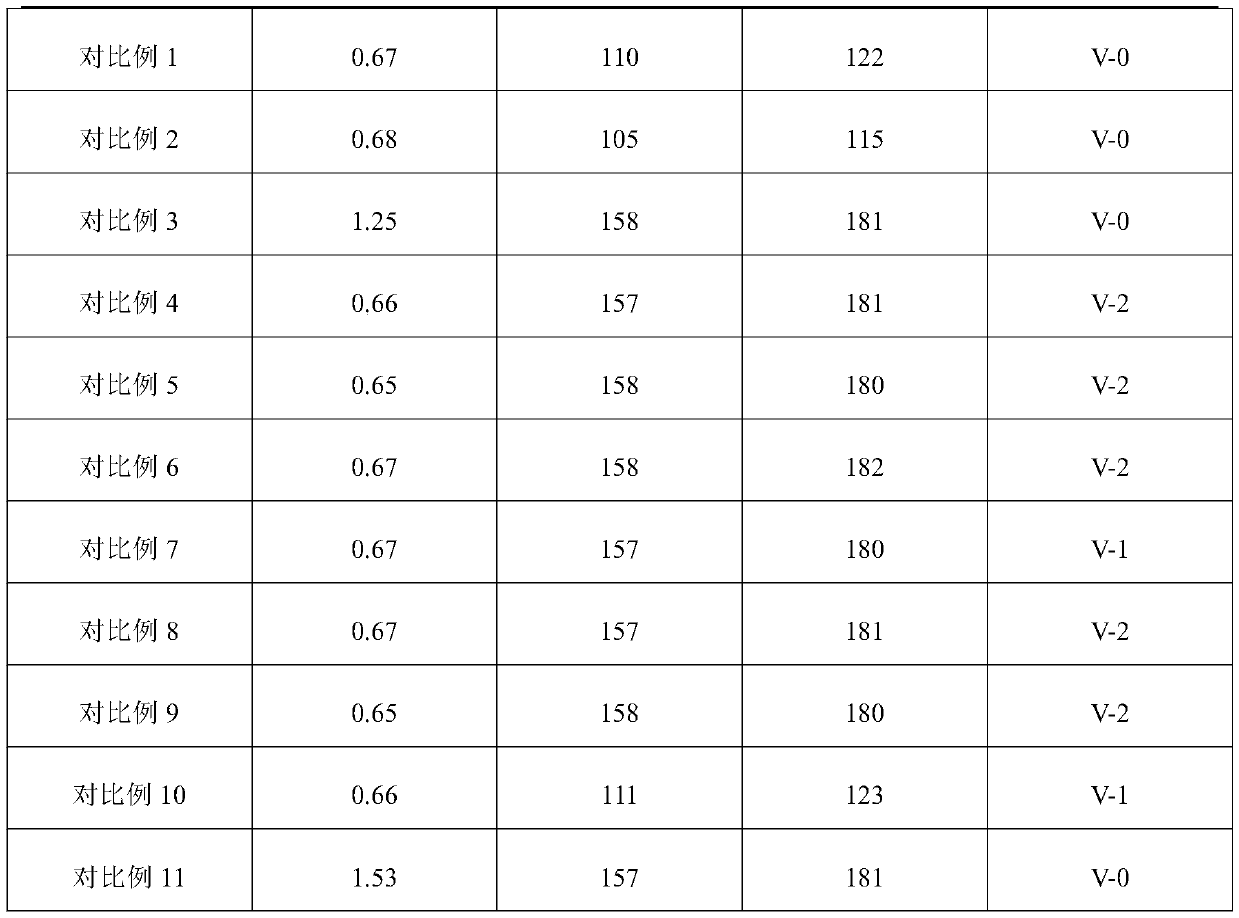

Examples

Embodiment 1

[0035] A method for preparing a flame-retardant polypropylene material for the upper cover of a new energy vehicle battery pack, the specific steps are as follows:

[0036] (1) First, carbon fiber powder, wollastonite powder, hollow glass microspheres, hexamethylenetetramine and coupling agent are mixed and ground to obtain the first additive and set aside;

[0037] (2) Then add polyvinyl alcohol, aluminum dihydrogen phosphate, sodium polyphosphate and polyhexamethyleneguanidine hydrochloride to the aqueous solution of sodium carboxymethyl cellulose, stir to dissolve, then add oxidized modified graphite, and ultrasonically oscillate After 30 minutes, the suspension was obtained, dried, and then kneaded by a torque rheometer to obtain the second additive for subsequent use;

[0038] (3) Finally, the polypropylene, the first additive obtained in step (1), and the second additive obtained in step (2) are melted and mixed with a twin-screw extruder, injected with a foaming agent, ...

Embodiment 2

[0052] A method for preparing a flame-retardant polypropylene material for the upper cover of a new energy vehicle battery pack, the specific steps are as follows:

[0053] (1) First, carbon fiber powder, wollastonite powder, hollow glass microspheres, hexamethylenetetramine and coupling agent are mixed and ground to obtain the first additive and set aside;

[0054] (2) Then add polyvinyl alcohol, aluminum dihydrogen phosphate, sodium polyphosphate and polyhexamethyleneguanidine hydrochloride to the aqueous solution of sodium carboxymethyl cellulose, stir to dissolve, then add oxidized modified graphite, and ultrasonically oscillate After 40 minutes, the suspension was obtained, dried, and kneaded by a torque rheometer to obtain the second additive for subsequent use;

[0055] (3) Finally, the polypropylene, the first additive obtained in step (1), and the second additive obtained in step (2) are melted and mixed with a twin-screw extruder, injected with a foaming agent, and p...

Embodiment 3

[0069] A method for preparing a flame-retardant polypropylene material for the upper cover of a new energy vehicle battery pack, the specific steps are as follows:

[0070] (1) First, carbon fiber powder, wollastonite powder, hollow glass microspheres, hexamethylenetetramine and coupling agent are mixed and ground to obtain the first additive and set aside;

[0071] (2) Then add polyvinyl alcohol, aluminum dihydrogen phosphate, sodium polyphosphate and polyhexamethyleneguanidine hydrochloride to the aqueous solution of sodium carboxymethyl cellulose, stir to dissolve, then add oxidized modified graphite, and ultrasonically oscillate After 30 minutes, the suspension was obtained, dried, and then kneaded by a torque rheometer to obtain the second additive for subsequent use;

[0072] (3) Finally, the polypropylene, the first additive obtained in step (1), and the second additive obtained in step (2) are melted and mixed with a twin-screw extruder, injected with a foaming agent, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com