Nickel-based superalloy for 3D printing and method for preparing nickel-based superalloy powder

A nickel-based superalloy, 3D printing technology, applied in the direction of metal processing equipment, process efficiency improvement, additive manufacturing, etc., can solve problems such as difficulty in meeting 3D printing requirements, low powder yield, poor composition uniformity, etc., to reduce Crack sensitivity, excellent mechanical properties, and high apparent density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0072] The method of the present invention is used for the following René 104 nickel-based superalloy, the added mass fraction is 0.08% rare earth element, and the weight percentage of the alloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9 Nb~0.05Zr~0.03B~0.04C~0.08Sc~the balance is Ni. The steps of preparing nickel-based superalloy powder for 3D printing by adopting the technical scheme of the present invention are as follows:

[0073] (1) Vacuum smelting: put the René 104 nickel-based superalloy raw material with a mass fraction of 0.08% rare earth Sc element into the crucible of the atomization powder making furnace, and conduct heating and smelting in a vacuum atmosphere of 0.05Pa by using an intermediate frequency power supply induction;

[0074] (2) Degassing: After the raw materials are melted and completely alloyed, vacuum degassing for 15 minutes;

[0075] (3) Refining: Fill the furnace with high-purity argon to 0.1MPa, the purity of argon is 99.99wt%, the oxygen...

Embodiment 2

[0083] The method of the present invention is used for the following René 104 nickel-based superalloy, the added mass fraction is 0.08% rare earth element, and the weight percentage of the alloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9 Nb~0.05Zr~0.03B~0.04C~0.08Y~the balance is Ni. The steps of preparing nickel-based superalloy powder for 3D printing by adopting the technical scheme of the present invention are as follows:

[0084] (1) Vacuum smelting: put the René 104 nickel-based superalloy raw material with a mass fraction of 0.08% rare earth Y element into the crucible of the atomization powder making furnace, and conduct heating and smelting in a vacuum atmosphere of 0.05Pa by using an intermediate frequency power supply induction;

[0085] (2) Degassing: After the raw materials are melted and completely alloyed, vacuum degassing for 15 minutes;

[0086] (3) Refining: Fill the furnace with high-purity argon to 0.1MPa, the purity of argon is 99.99wt%, the oxygen c...

Embodiment 3

[0091] The method of the present invention is used for the following René 104 nickel-based superalloy, the added mass fraction is 0.08% rare earth element, and the weight percentage of the alloy is: 20.6Co~13Cr~3.4Al~3.9Ti~3.8Mo~2.1W~2.4Ta~0.9 Nb~0.05Zr~0.03B~0.04C~0.04Sc~0.04Y~the balance is Ni. The steps of preparing nickel-based superalloy powder for 3D printing by adopting the technical scheme of the present invention are as follows:

[0092] (1) Vacuum smelting: Put the René104 nickel-based superalloy raw material with added mass fraction of 0.04% Sc and 0.04% Y element into the crucible of the atomizing powder making furnace, and heat it by induction in a vacuum atmosphere of 0.05Pa smelting;

[0093] (2) Degassing: After the raw materials are melted and completely alloyed, vacuum degassing for 15 minutes;

[0094] (3) Refining: Fill the furnace with high-purity argon to 0.1MPa, the purity of argon is 99.99wt%, the oxygen content in argon is 0.00006wt%, and the molten ...

PUM

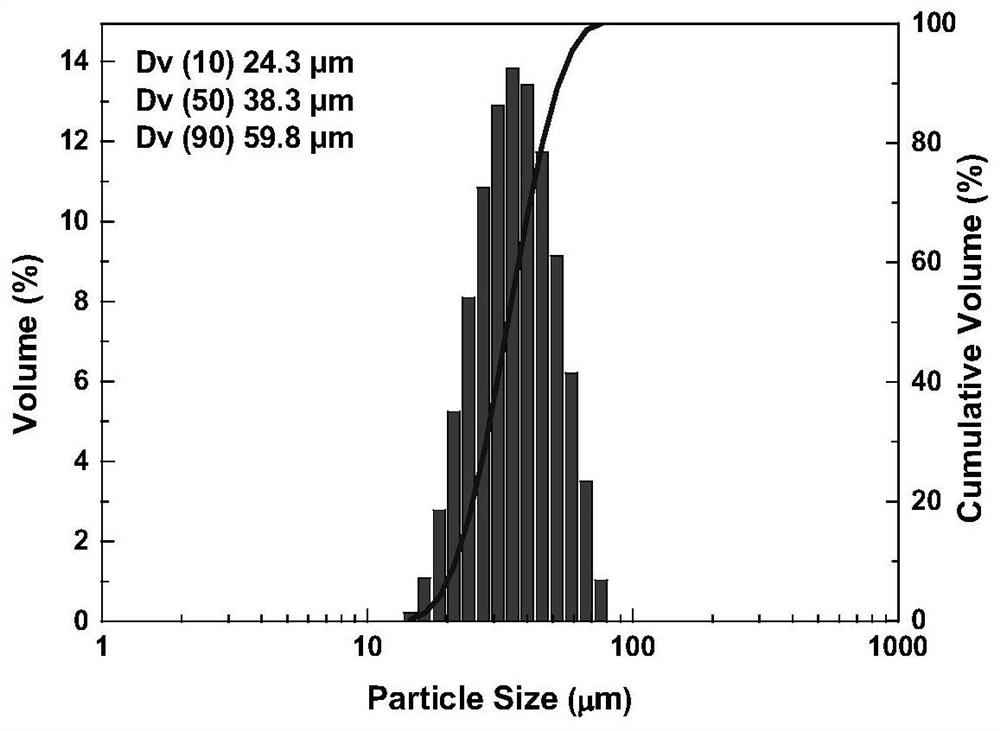

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com