Glass fiber enhanced PA66 base plate material for high speed rail and preparation method thereof

A high-speed rail and track technology, applied in the field of glass fiber reinforced PA66 high-speed rail substrate material and its preparation, can solve the problem that the product is difficult to meet the requirements of safety and high stability, reduce material rigidity, aging resistance, and extrude granulation is easy to fluctuate and other problems, to achieve the effect of high appearance quality, improved water absorption and dimensional stability, excellent processing performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

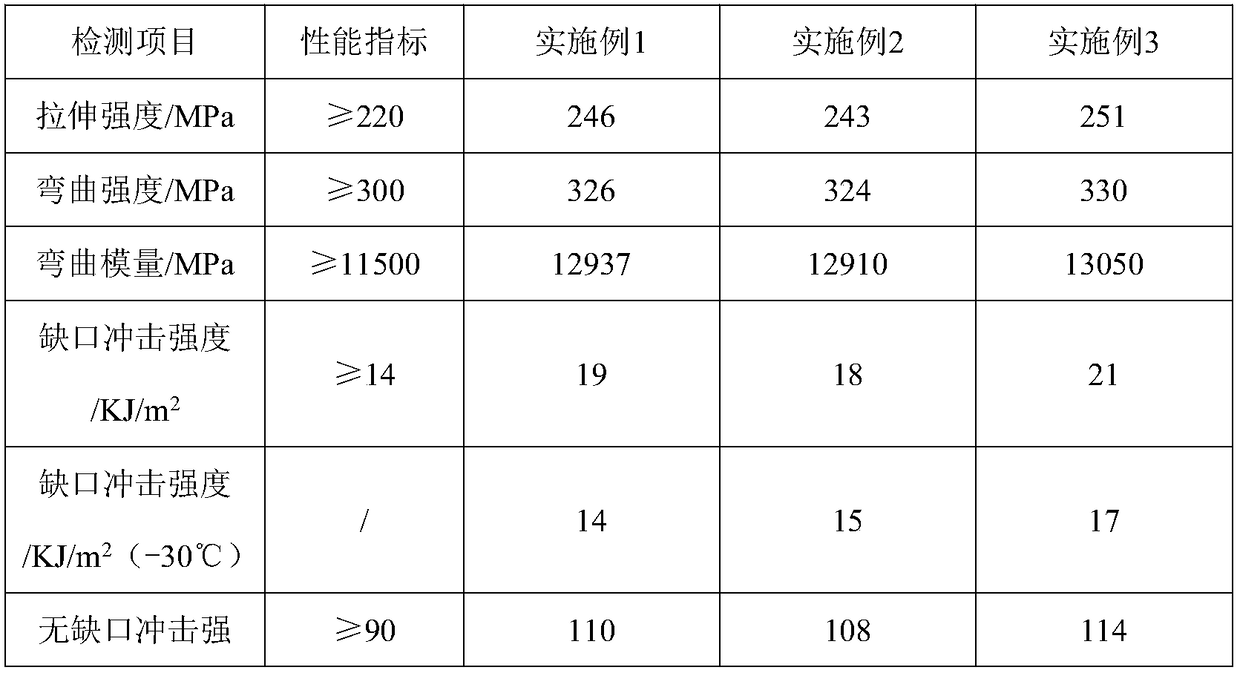

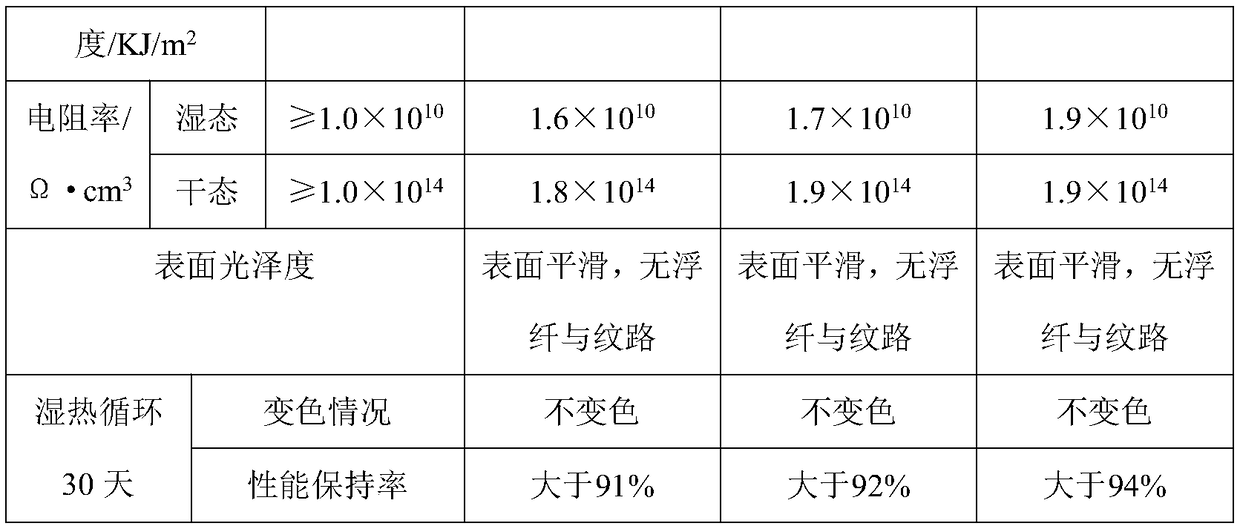

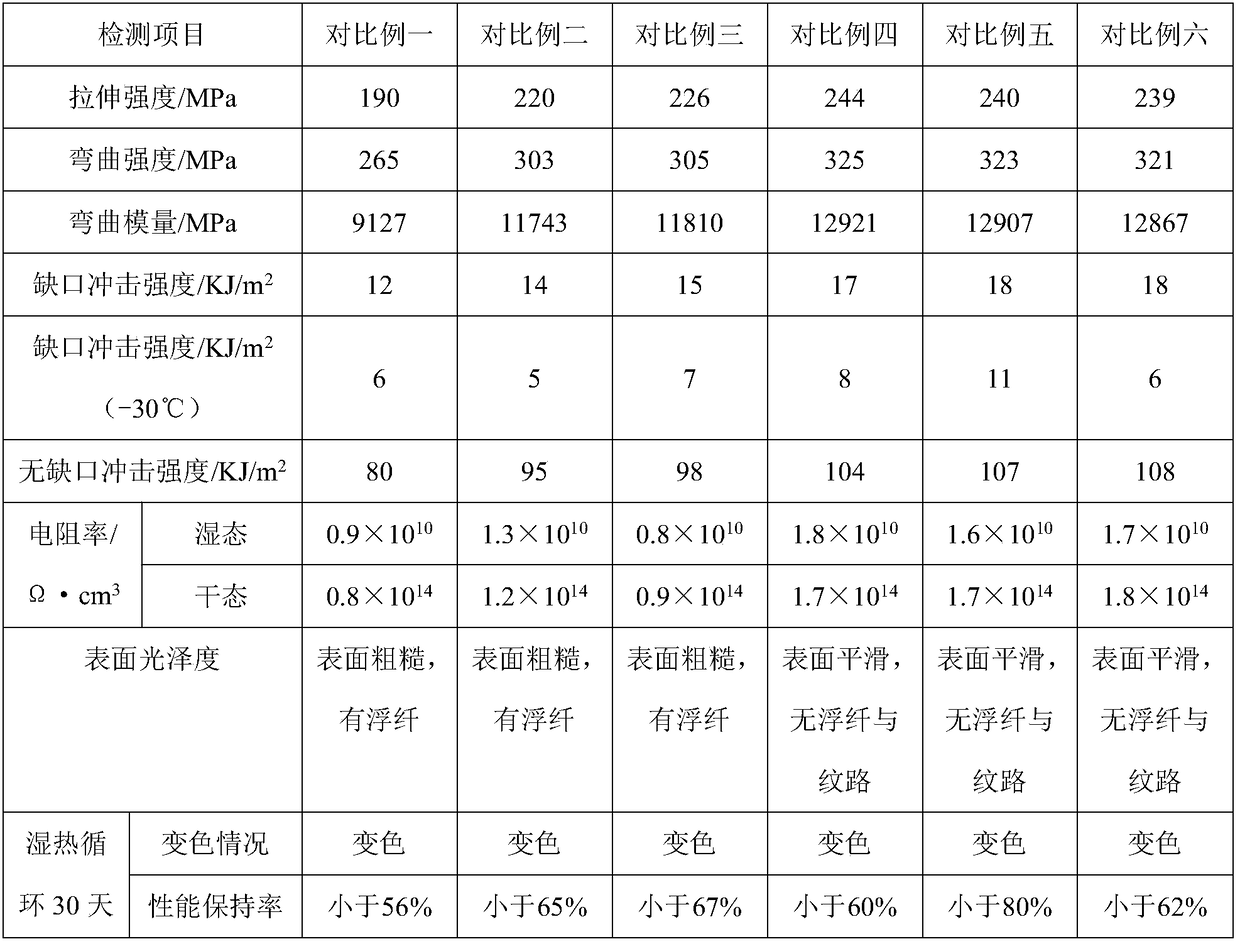

Examples

Embodiment 1

[0029] Embodiment 1, glass fiber reinforced PA66 high-speed rail track substrate material of the present invention and its preparation

[0030] formula:

[0031] PA66 resin (relative viscosity 2.0-2.2) 29.1kg, PA6T resin (relative viscosity 2.6-2.8) 10.0kg, antioxidant (composed of antioxidant 1010 and antioxidant 1098 in a weight ratio of 2:1) 0.6kg , 0.3 kg of silicone, 8.0 kg of 2000-mesh glass beads, 1.0 kg of toughening agent POE, 51.0 kg of alkali-free chopped glass fibers (5.0-8.0 mm in length, 10-14 μm in diameter).

[0032] Preparation:

[0033] S1. Put the PA66 resin and PA6T resin of the formula into the high mixer, and stir for 10 minutes at a rotation speed of 500r / min to obtain a mixed resin;

[0034]S2. Premix the antioxidant, silicone, glass microspheres, toughening agent POE and alkali-free chopped glass fiber for 5 minutes, then put it into the mixed resin, and stir for 10 minutes at a speed of 1000r / min , get the premix;

[0035] S3. Transfer the premixe...

Embodiment 2

[0036] Embodiment 2, glass fiber reinforced PA66 high-speed rail track substrate material of the present invention and its preparation

[0037] formula:

[0038] PA66 resin (relative viscosity 2.0-2.2) 33.5kg, PA6T resin (relative viscosity 2.6-2.8) 5.0kg, antioxidant (composed of antioxidant 1010 and antioxidant 1098 in a weight ratio of 3:1) 1.0kg , 0.5 kg of OP wax, 9.0 kg of 2000-mesh glass beads, 2.0 kg of toughening agent POE, 49.0 kg of alkali-free chopped glass fibers (5.0-8.0 mm in length, 10-14 μm in diameter).

[0039] Preparation:

[0040] S1. Put the PA66 resin and PA6T resin of the formula into the high mixer, and stir for 5 minutes at a rotation speed of 800r / min to obtain a mixed resin;

[0041] S2. Premix the antioxidant, OP wax, glass microspheres, toughening agent POE and alkali-free chopped glass fiber for 10 minutes, then put them into the mixed resin, and stir for 15 minutes at a speed of 1500r / min , get the premix;

[0042] S3. Transfer the premixed ...

Embodiment 3

[0043] Embodiment 3, glass fiber reinforced PA66 high-speed rail track substrate material of the present invention and its preparation

[0044] formula:

[0045] PA66 resin (relative viscosity 2.0-2.2) 32.3kg, PA6T resin (relative viscosity 2.6-2.8) 8.0kg, antioxidant (composed of antioxidant 1010 and antioxidant 1098 at a weight ratio of 2.5:1) 0.8kg , 0.4 kg of OP wax, 7.0 kg of 2000-mesh glass beads, 1.5 kg of toughening agent POE, 50.0 kg of alkali-free chopped glass fibers (5.0-8.0 mm in length, 10-14 μm in diameter).

[0046] Preparation:

[0047] S1. Put the PA66 resin and PA6T resin of the formula into the high mixer, and stir for 10min at a speed of 600r / min to obtain a mixed resin;

[0048] S2. Premix the antioxidant, OP wax, glass microspheres, toughening agent POE and alkali-free chopped glass fiber for 10 minutes, then put them into the mixed resin, and stir for 10 minutes at a speed of 1500r / min , get the premix;

[0049] S3. Transfer the premixed material in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com