E-grade paper tube base paper and preparation process thereof

A preparation process and paper tube technology, which are applied in the field of E-grade paper tube base paper and its preparation process, can solve the problems affecting the appearance quality of paper corner protection products, high cost of corner protection, low strength index, etc., and achieve good appearance quality and good quality. The effect of high uniformity and strength index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

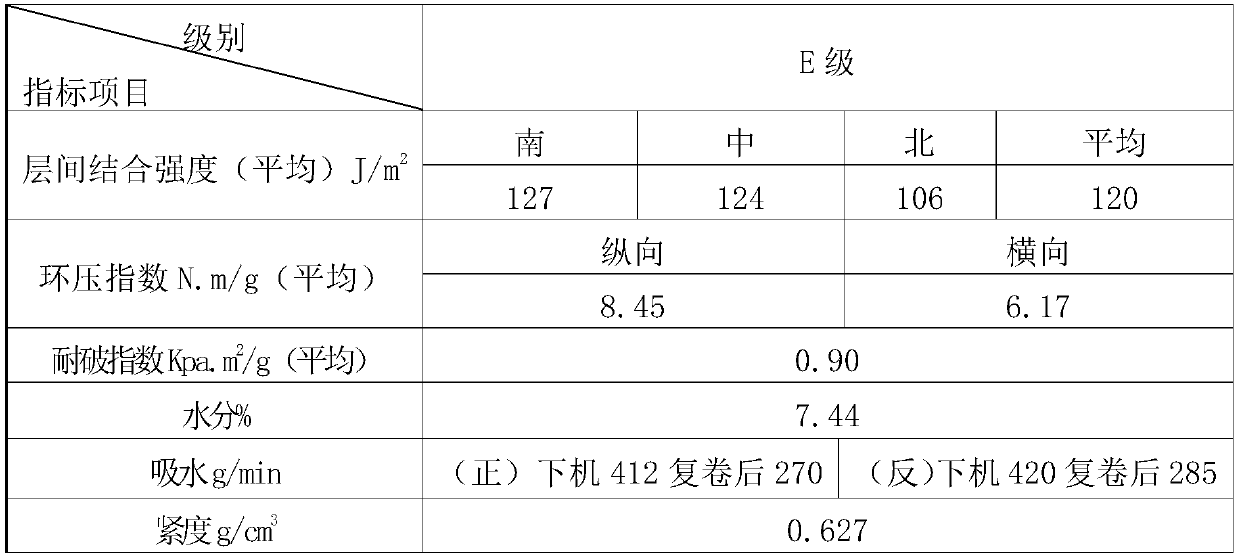

[0027] An E-grade paper tube base paper, the basis weight of the paper tube base paper is 420g / m 2 , 500g / m 2 or 520g / m 2 , the allowable error range of lateral quantitative is ±3%, the allowable error range of longitudinal quantitative is 1.5%; the tightness is 0.60~0.62g / cm 3 , The paper moisture is 6.0~8.0%; the longitudinal ring pressure index is 7.5±0.5N.m / g, and the interlayer bonding strength is 100±20J / m 2 .

[0028] A preparation process for E-grade paper tube base paper, comprising the following steps: pulping, preparing spray starch, paper forming, rewinding and packaging; pulping is separated and beating is performed, and spray starch is sprayed between layers when paper is formed. The preparation steps are as follows:

[0029] 1) pulping

[0030] Prepare raw materials, including waste paper BTG and wood fiber. When pulping, separate waste paper BTG and wood fiber and use different pulpers for pulping. Waste paper BTG is crushed with a 50D pulper, and heavy im...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com