Method for making hand-made paper by dry method

A soil-based paper and dry-process technology, which is applied in papermaking, paper machines, textiles and papermaking, etc., to achieve the effects of less drying steam consumption, accurate quantification, and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

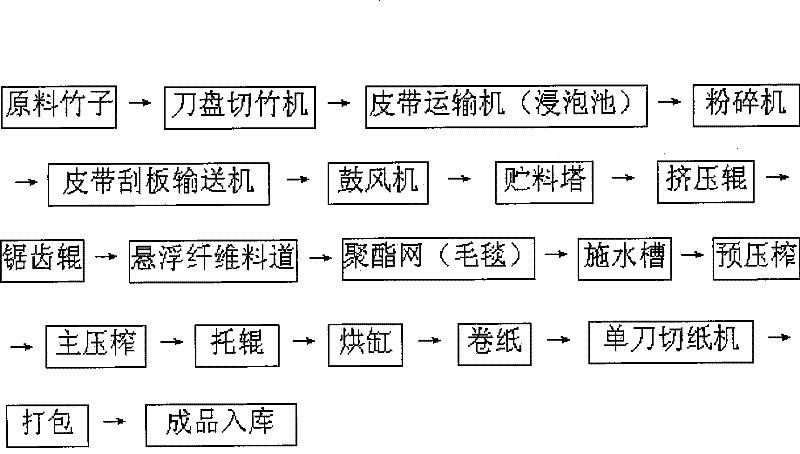

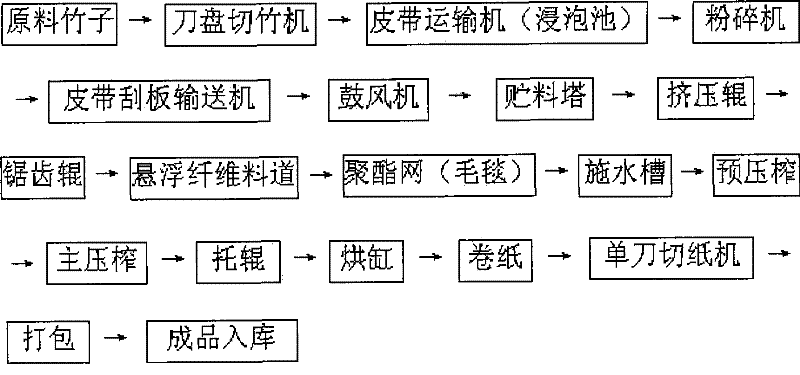

Image

Examples

Embodiment

[0040] The raw bamboo is cut into bamboo pieces with a length of 30mm-50mm by a cutter head bamboo cutting machine, and the bamboo pieces are slowly passed through the lye pool by a belt conveyor. The time is generally 5-10 minutes, and the lye used has a concentration of 10-20 % sodium hydroxide solution, the bamboo chips in the lye pool are stacked for 24 hours to fully absorb the lye, so that the lignin between the fibers is dissolved, and then the bamboo chips that have absorbed the lye are input into the grinder, and the grinder The high-speed rotating flying blade inside cuts the bamboo material, separates the filaments, and brooms the fiber. The high-speed rotating flying blade collides with the raw material, and the friction generates a lot of heat energy to reduce the water content of the pulverized pulp from 40% to 15%. Heating and evaporating the pulp moisture can meet the pulp requirements of the drylaid paper machine and save energy.

[0041] The dry pulp in the p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com