Double brocade woven label with warp net shuttle and its weaving method

A technology of weaving labels and fabric weaving, which is applied in the direction of textiles, papermaking, fabrics, textiles, etc. It can solve the problems of affecting weaving and shearing processing, affecting the appearance of woven labels, and high waste rate of woven labels, so as to avoid color penetration, Reduce the color through the phenomenon, the effect of uniform quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

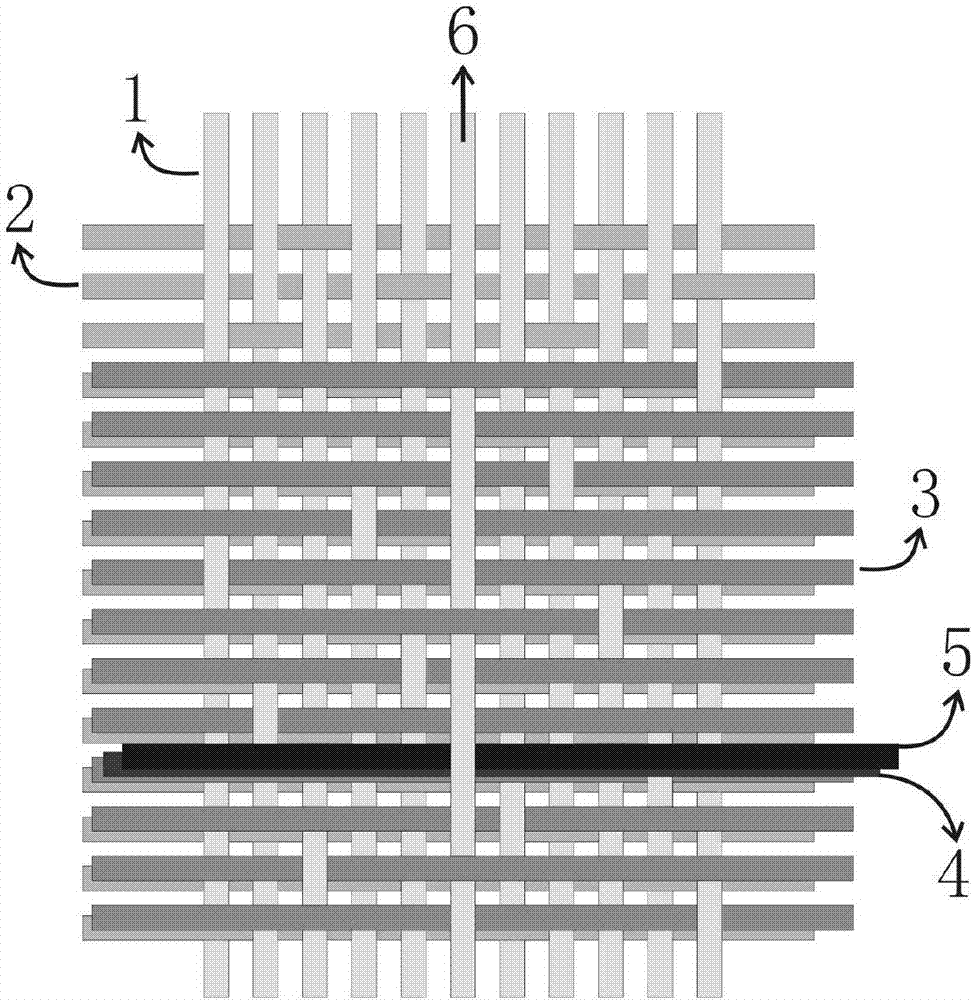

[0052] Example 1 5 pieces of 2 enclave organization effect + 10 pieces of 7 flying lining effect + 5 / 2 effect of drawing warp net shuttle + woven label of double-large net shuttle

[0053] The effect of the woven label in this embodiment is 5 pieces of 2 enclave tissue effects+10 pieces of 7 flying lining effects+drawing warp net shuttle 5 / 2 effect+double-large net shuttle, which specifically includes the following steps:

[0054] 1. Before designing the design of the woven label, determine the process parameters such as the warp and weft density and yarn thickness of the woven label. The woven label of the present embodiment ( Figure 20 ) is 84mm in length and 64mm in width; the number of patterned warp yarns is 370, the number of weft yarns is 640, and the total number of shuttles is 2487; the warp density is 146 pieces / inch, and the weft density is 192 pieces / inch; the warp yarn is 75D white, and the weft yarn system is : 1. Ground shuttle __50D white; 2. Lining shuttle _...

Embodiment 2

[0061] Example 2 5 pieces of 2 enclave tissue effects + 5 pieces of 2 flying lining effects + 3 / 1↗ effect of drawing warp net shuttles + woven labels with double size and offset net shuttles

[0062] The effect of the woven label in this embodiment is the effect of 5 pieces of 2 enclave tissue + 5 pieces of 2 flying lining effect + the effect of drawing warp net shuttle 3 / 1↗ + double the size and offset of the net shuttle, which specifically includes the following steps:

[0063] (1) Before designing the design of the woven label, determine the process parameters such as the warp and weft density and yarn thickness of the woven label. The warp density of the present embodiment is 146 threads / inch, and the weft density is 146 threads / inch; the warp yarn thickness of the woven label is 75D, and the weft yarn thickness is 75D.

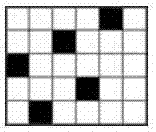

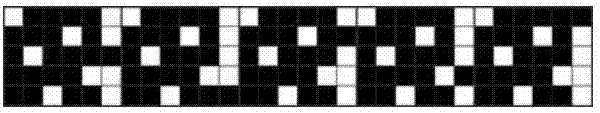

[0064] (2) In the woven label flower design software, make a new type of matching organization with the effect of 5 pieces of 2 enclaves + the effect of ...

Embodiment 3

[0071] Example 3: 8 woven labels with 5-enclave tissue effect + 8 5-fly lining effect + 3 / 1↖ effect of warp-drawing net shuttle

[0072] The effect of the woven label in this embodiment is the effect of 8 pieces of 5 enclave tissue + the effect of 8 pieces of 5 flying lining + the effect of drawing warp net shuttle 3 / 1↖, which specifically includes the following steps:

[0073] (1) Before designing the design of the woven label, determine the process parameters such as the warp and weft density and yarn thickness of the woven label. The warp density of this embodiment is suitable for 140-152 threads / inch, and the weft density is suitable for 112-228 threads / inch; the thickness of warp yarns for woven labels is suitable for 50D-100D, and the thickness of weft yarns is suitable for 30D-150D.

[0074] (2) In the woven label design software, make 8 pieces of 5 enclave weave effects + a new supporting structure with the effect of pumping net shuttle 3 / 1↖: based on ordinary woven la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com