A papermaking process of single-sided blue engineering paper

A papermaking process and engineering paper technology, applied in the field of papermaking, can solve the problems of low absorption rate of coating ink, different shades of paper surface, poor air permeability, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

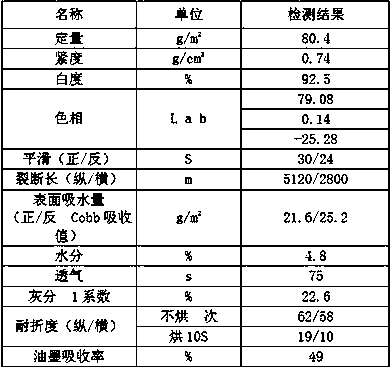

[0045] Example 1 A papermaking process of single-sided blue engineering paper

[0046] 1. Pulping

[0047] (1) Preparation of long fibers: pulverized by a hydropulper, and the 2.6mm bleached kraft softwood long fiber wood pulp was passed through a double disc refiner beater, the long fiber beating current was 300A, the beating concentration was 4.0%, and the beating degree was 35° SR;

[0048] (2) Preparation of poplar pulp: self-made poplar pulp with a fiber length of 0.85-0.9 mm is transferred through the pulp pool to the knocking pool, and then passed through a double-disk beating machine with a beating current of 270A and a beating concentration of 4.1%. The degree of beating is 36°SR, and the slurry is prepared.

[0049] 2. Mixed pulp

[0050] Start the automatic batching equipment, and pump the long-fiber pulp and poplar pulp into the mixing tank respectively. The ratio of long-fiber pulp to poplar pulp is 1.2:1, that is, the long-fiber pulp accounts for 55% of the tot...

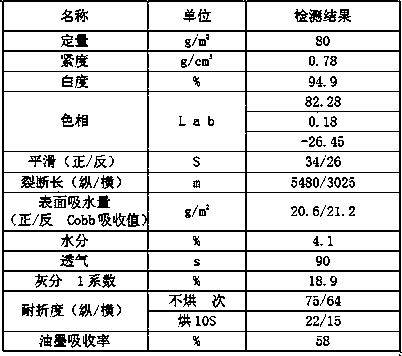

Embodiment 2

[0070] Example 2 A papermaking process of single-sided blue engineering paper

[0071] 1. Pulping

[0072] (1) Preparation of long fibers: pulverize through a hydropulper, and pulverize 2.7mm bleached kraft coniferous long fiber wood pulp through a hydropulper, transfer it to the knocking pool, pass through a double disc mill beater, and Fiber beating current 310A, beating concentration 4.0%, beating degree 37°SR;

[0073] (2) Preparation of poplar pulp slurry: self-made poplar pulp with a fiber length of 0.87 mm is transferred to the front pool through the pulp pool, and then transferred to the rear pool of poplar pulp through a double-disc mill beater, and the beating is controlled The power is 120-145kwh, the beating current is controlled at 280 A, the beating concentration is 4.1%, and the beating degree is 36°SR to prepare poplar pulp.

[0074] 2. Mixing and pulping

[0075] Start the automatic batching equipment, and pump the long-fiber pulp and poplar pulp into the m...

Embodiment 3

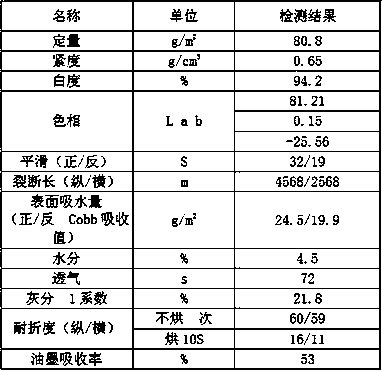

[0095] Example 3 A papermaking process of single-sided blue engineering paper

[0096] 1. Pulping

[0097] (1) Preparation of long fibers: pulverize through a hydropulper, and pulverize 2.7mm bleached kraft coniferous long fiber wood pulp through a hydropulper, transfer it to the knocking pool, pass through a double disc mill beater, and Fiber beating current 320A, beating concentration 4.0%, beating degree 38°SR;

[0098] (2) Preparation of poplar pulp slurry: self-made poplar pulp with a fiber length of 0.87 mm is transferred to the front pool through the pulp pool, and then transferred to the rear pool of poplar pulp through a double-disc mill beater, and the beating is controlled The power is 120-145kwh, the beating current is controlled at 280A, the beating concentration is 4.1%, and the beating degree is 38°SR to prepare poplar pulp pulp.

[0099] 2. Mixed pulp

[0100] Start the automatic batching equipment, and pump the long fiber pulp and poplar pulp into the mixin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com